AR (Anti-Reflective) coatings are optical thin films applied to glass surfaces to minimize light reflection and maximize transmission(Up to 99%), effectively reduce environmental light interference to present a clear and real image.

In the glass industry, this technology has revolutionized applications across sectors such as automotive, display panel, solar energy, consumer electronics, medical equipments and optical lens, offering both functional and aesthetic benefits.

1.Introduction of three AR Coating Methods

Dip coating, Magnetron sputtering, and Vacuum evaporation are three common AR (anti-reflection) coating technologies, each with significant differences in principle, process, performance, and application scenarios. The following is a detailed comparison from three dimensions: core differences, advantages/disadvantages, and applicable fields.

|

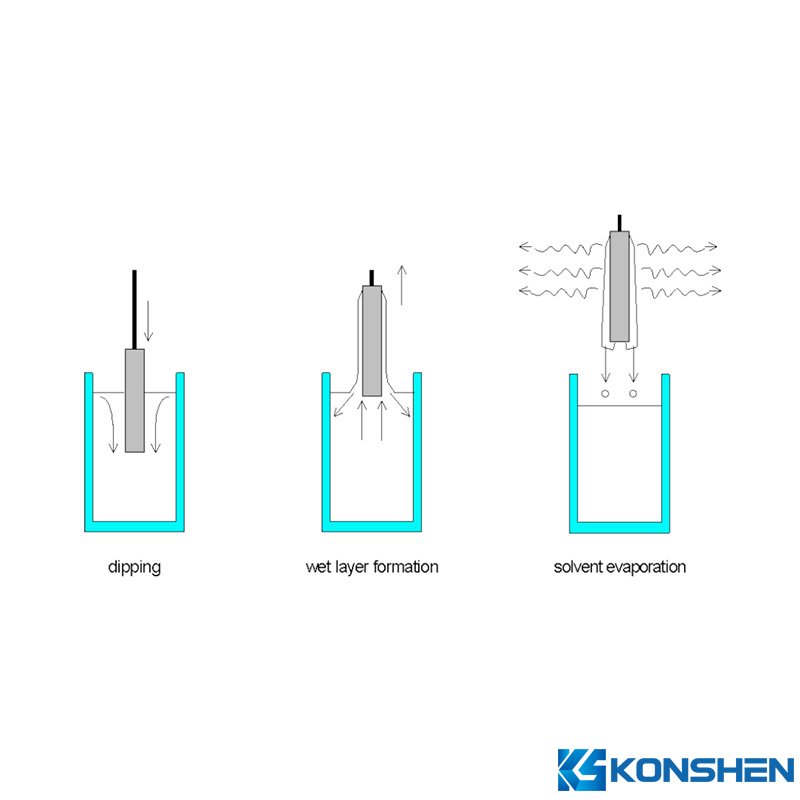

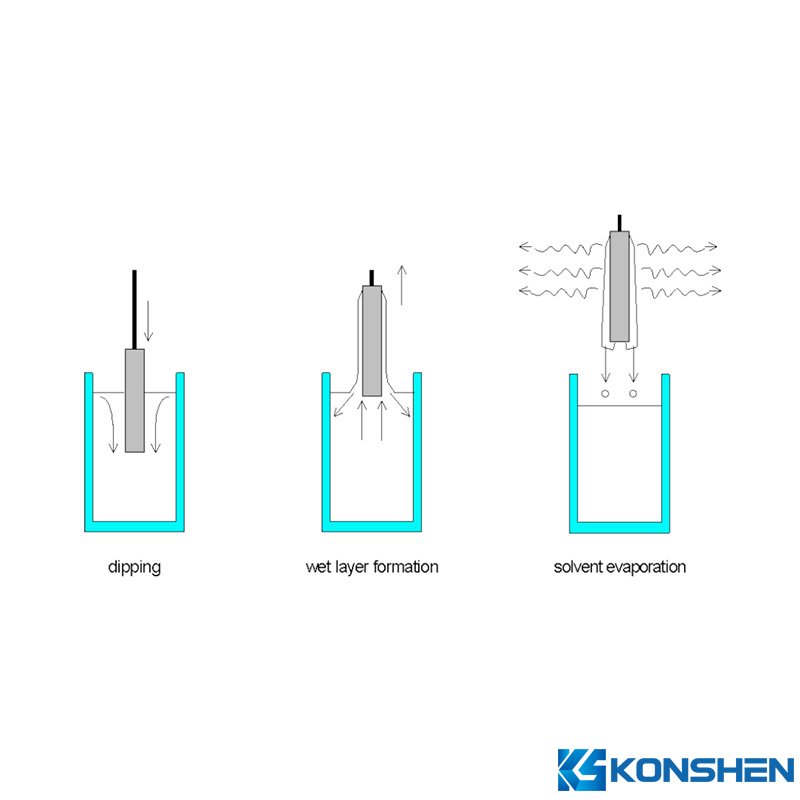

1.1 Dip Coating: A Low-Cost Method for AR Coating on Glass

A liquid-phase coating technique where the glass substrate is immersed in a solution containing coating materials (e.g., SiO₂ sol, silicone resin). By controlling the withdrawal speed (typically 0.1–5 mm/s), a uniform film forms on the substrate surface. After drying and curing (e.g., high-temperature sintering or UV curing), an AR layer is created.

Low cost and suitable for photovoltaic products or low-requirement picture frame items, but with poor light transmittance and scratch resistance.

|

|

1.2 Magnetron Sputtering AR Coating on Glass: High Precision, Excellent Performance

A type of physical vapor deposition (PVD). The glass original sheet is placed in a vacuum coating chamber, and a magnetic field is applied on the surface of the target material to accelerate argon ions in the argon plasma to bombard the target material. The target atoms are sputtered out and deposited on the glass surface to form a coating. It can precisely control the coating thickness and composition by accurately controlling parameters such as sputtering time, power, and gas flow, and is often used to prepare multi-layer film structures.

Suitable for high-performance optics, touch panels, wear-resistant surfaces. Offers optimal performance and excellent optical effects, but features expensive equipment and slow production speed.

|

|

1.3 Vacuum Evaporation AR Coating for Glass: Flexible Method with Optical Clarity

In a high-vacuum environment (vacuum degree 10⁻⁴–10⁻⁶ Pa), coating materials (e.g., metal oxides, fluorides) are evaporated into a gaseous state via resistance heating or electron beam bombardment. Gaseous molecules condense on the glass surface to form a thin film, with thickness controlled by evaporation rate and time.

Features a flexible process and good optical performance, suitable for optical instruments and electronic devices, but with slightly inferior adhesion and hardness.

|

2.Technical Comparison Table of Three AR Coating Methods

| Feature |

Dip-Coated AR |

Magnetron Sputtered AR |

Vacuum Evaporated AR |

| Coating Environment |

Atmospheric or clean oven |

High vacuum chamber |

High vacuum chamber |

| Material Deposition |

Chemical sol-gel deposition |

Plasma-based sputtering |

Thermal evaporation |

| Coating Precision |

Medium |

Very High (multi-layer possible) |

High |

| Layer Adhesion |

Moderate |

Excellent |

Good |

| Surface Hardness |

3–5H |

≥6H |

4–6H |

| Typical Transmission |

92–94% |

96–98.5% |

94–97% |

| Scratch Resistance |

Moderate |

Excellent |

Good |

| Production Cost |

Low |

High |

Moderate to High |

| Uniformity (on large glass) |

Good |

Good |

Maybe limited by thickness |

| Environmental Stability |

Moderate |

High |

Moderate |

3. Application Fields of AR Coating Glass

3.1 Application of AR coating Glass In Display Panels/Touch Screens

Modern electronic display products have extremely high requirements for display clarity. AR glass can significantly improve the display effect of devices such as smartphones, tablets, and TV screens, reducing glare interference in strong light or outdoor environments and delivering clearer, more realistic images.

3.2 Application of AR Coating Glass in Photovoltaic Field

The role of AR glass in photovoltaic power generation equipment is to improve the efficiency of sunlight passing through the glass panel into the photoelectric conversion layer. Its low reflectivity can significantly increase light absorption, thereby boosting the power generation efficiency of solar panels.

3.3 Application of AR Coating Glass in Optical Instrument Field

Used in camera lenses, telescopes, etc., it can reduce reflection between lenses, improve imaging clarity and color reproduction, and eliminate stray light and glare. In laser processing equipment, it can improve laser transmittance and enhance processing accuracy and efficiency.

3.4 Application of AR Coating Glass in Museum Display Cases and Art Frames

AR glass, with its extremely low reflectivity, is widely used in museum display cases and high-end art frames. It effectively reduces reflections from lights and the environment, allowing viewers to appreciate the original appearance and details of exhibits unobstructed. Meanwhile, it boasts excellent light transmittance and UV resistance, protecting precious cultural relics and paintings from light damage, and enhancing the quality and professionalism of exhibitions.

3.5 Application of AR Coating Glass in Automotive HUD (Head-Up Display) and Instrument Panels

In the high-end automotive sector, HUD systems project information through the windshield. Using AR glass can reduce reflection interference, enabling drivers to clearly read navigation, speed, and other information even in direct sunlight or during night driving. Additionally, it is applied in in-vehicle instrument panels, navigation screens, and other display systems, ensuring high brightness, high clarity, and operational safety.

3.6 Application of AR Coating Glass in Medical Instruments

In scenarios requiring extremely high image clarity, such as medical imaging equipment, surgical navigation systems, and laboratory observation windows, AR glass ensures that medical personnel obtain interference-free, high-definition image data during operations. Its stable surface performance also helps maintain long-term cleanliness and accurate display of equipment, making it an indispensable component in modern medical devices.

| Application Industry |

Dip-Coated AR |

Magnetron Sputtered AR |

Vacuum Evaporated AR |

| Display Panels/Touchscreens |

❌ No |

✅ Best choice |

✅ Optional |

| Precision Optical Lenses |

❌ No |

✅ Optional |

✅ Best choice |

| Camera Lens Covers |

❌ No |

✅ Optional |

✅ Best choice |

| Medical Devices |

❌ No |

✅ Strong resistance |

✅ Good performance |

| Military / Aerospace Optics |

❌ No |

✅ Best choice |

✅ Optional |

| House Appliance |

❌ No |

✅ For premium products |

✅ Mid-range options |

| Solar Glass Panels |

✅ Yes (cost-effective) |

❌ Less used (expensive) |

❌ Rare |

| Picture Frame/Art Display |

✅ Yes (cost-effective) |

✅ Optional |

❌ Rare |

Conclusion:

In conclusion, AR (Anti-Reflective) coating technologies—Dip Coating, Magnetron Sputtering, and Vacuum Evaporation—each offer unique advantages, trade-offs, and application scenarios. Dip Coating stands out for its low production cost, making it ideal for solar panels and decorative glass products. Magnetron Sputtering delivers the highest precision and durability, suitable for high-end optical and touchscreen devices. Vacuum Evaporation, with its flexible process and good optical performance, is well-suited for optical instruments and electronic components.

Choosing the right AR coating method depends on your specific performance, cost, and application requirements. By understanding the differences in process technology and functional outcomes, manufacturers and designers can make informed decisions to achieve optimal product performance and cost-efficiency.

KS Glass have the most advanced AR coating equipment in the glass industry and rich production experience. Contact us and consult the most suitable AR coating solution for you.

Coated GlassElevate your projects with advanced coated glass solutions from KS Glass.

Coated GlassElevate your projects with advanced coated glass solutions from KS Glass. Cover GlassUpgrade your devices with our cover glass.

Cover GlassUpgrade your devices with our cover glass. Solar Panel GlassUpgrade your devices with our cover glass.

Solar Panel GlassUpgrade your devices with our cover glass. Glass MaterialDiscover the endless possibilities of working with large glass material.

Glass MaterialDiscover the endless possibilities of working with large glass material.