In recent years, flexible display technology has risen rapidly, revolutionizing product design from foldable smartphones and rollable tablets to electronic books and wearable devices. The popularization of flexible screens has brought new challenges to cover materials — they must now combine lightweight form, bendability, durability, and optical purity while maintaining high resolution, contrast, and color saturation.

Early flexible displays primarily used CPI (Colorless Polyimide) plastic films as protective cover plates. Although CPI offers certain flexibility, it suffers from low light transmittance (around 88–90%), limited surface hardness (~3H), susceptibility to scratches and yellowing, and poor thermal stability during high-temperature deposition or long-term use. These drawbacks make CPI inadequate for high-end flexible displays that demand both premium image quality and long-term reliability.

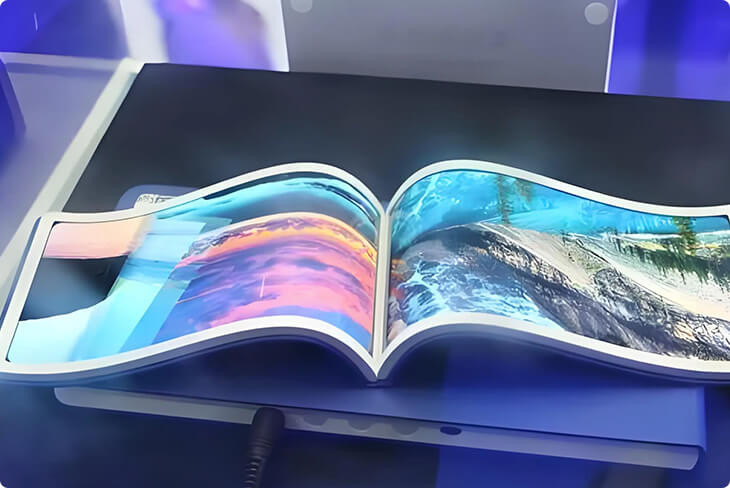

In this context, UTG (Ultra Thin Glass) has emerged as a breakthrough solution. With its superior optical clarity, hardness, heat resistance, and flexibility, UTG has become the key cover material for next-generation flexible displays, gradually replacing CPI and other polymer films to become the new industry standard.

The exceptional performance of UTG stems from its high-purity glass substrate and advanced forming techniques. The most commonly used UTG substrate is aluminosilicate glass, which features extremely low iron content and achieves light transmittance of 91–92%, minimizing light absorption and color distortion to maintain high brightness and vivid colors.

UTG is typically produced by the Overflow Down-Draw process, where molten glass naturally overflows from a high-temperature trough and forms a continuous sheet without mechanical contact, achieving exceptional flatness and defect-free surfaces, ideal for high-resolution flexible OLED displays.

Another approach is the thinning process, where conventional 0.3–0.5 mm glass is chemically or mechanically thinned to 0.03–0.1 mm, achieving ultra-flexibility without compromising surface integrity.

|

Company |

Model |

Thickness Range (mm) |

Key Features |

|

SCHOTT |

Xensation® Flex |

0.03 – 0.10 |

High transparency, supports R2 mm folding |

|

Corning |

Willow® Glass |

0.03 – 0.10 |

Excellent flexibility, suitable for rollable displays |

|

NEG |

G-Leaf™ |

0.03 – 0.10 |

Exceptional flatness, can be wound for storage |

The flexibility of UTG comes not only from its thinness but also from precise bending and stress control during manufacturing. Through thermal bending or stress-controlled bending, UTG can achieve specific curvatures suitable for foldable or rollable display modules.

Current mainstream UTG products can achieve bending radii of R2–R5 mm, with some high-performance variants reaching R1.5 mm. Even after bending, the glass maintains high optical uniformity and surface smoothness without stress whitening or light scattering. Compared with CPI, UTG offers much longer folding endurance — over 200,000 folding cycles without surface degradation or image distortion. For example, Samsung’s Galaxy Z Fold series utilizes ~0.03 mm UTG cover glass combined with a patented bending process, delivering a smooth folding experience while retaining the premium touch feel and scratch resistance characteristic of glass.

Chemical Strengthening for Durability

Although extremely thin, UTG achieves high mechanical strength through chemical strengthening. During this process, glass is immersed in a molten KNO₃ bath, where potassium ions (K⁺) replace sodium ions (Na⁺) on the surface, forming a compressive stress layer that prevents crack propagation and enhances impact resistance.

After strengthening, UTG can reach surface compressive stress levels of 600–900 MPa and a surface hardness up to 7H, far exceeding CPI’s 3H. Chemical strengthening also significantly improves humidity and heat resistance, ensuring consistent flexibility and touch performance under complex environmental conditions — making UTG the ideal combination of flexibility and safety.

Beyond its material properties, UTG can be enhanced with various surface coatings to further optimize optical, tactile, and functional performance. These coatings not only enhance transparency and durability but also expand the design flexibility of flexible electronics.

|

Samsung Galaxy Z Fold Series |

Adopts dual-layer AR + AF coated UTG, combining low reflection and anti-fingerprint features. This enhances image clarity by ~15% and provides a smoother touch experience. |

|

Huawei Mate X Series |

Uses ITO + AF coating for flexible capacitive touch, balancing conductivity, cleanliness, and scratch resistance. |

|

Xiaomi MIX Fold Series |

Certain models feature a triple-layer AR + AG + AF structure for anti-glare, anti-reflection, and easy-clean performance, ensuring outstanding visual experience both indoors and outdoors. |

Ultra-thin UTG glass can also accommodate high-precision screen printing for border masking, alignment marks, or functional graphics. Due to its excellent flatness, printing can be performed at the micron level, ensuring both optical uniformity and circuit precision in flexible modules. Printed layers can also serve as structural reinforcement and decorative elements, giving the cover glass both aesthetic appeal and functional integration.

Ultra Thin Glass (UTG), with its high transmittance, superior hardness, outstanding durability, and customizable optical functionality, successfully bridges the long-standing gap between flexibility and reliability in flexible devices. From foldable smartphones and rollable TVs to wearable displays and automotive curved screens, UTG is steadily replacing CPI to become the core material of next-generation flexible displays.

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us