In the field of glass fabrication, edge treatment is far more than just a finishing touch—it directly influences the safety, visual appeal and durability of the glass product. Whether the glass is used in architectural panels, furniture, electronics, or automotive components, how its edges are processed can determine not only how it performs, but also how long it lasts.

Raw-cut edges left untreated can be dangerously sharp, prone to chipping, and structurally weaker due to micro-cracks or stress points. This is why edge finishing has become a crucial part of the production process, typically carried out using high-precision CNC edge grinding machines. These systems ensure clean, consistent edges and allow for a wide range of finishes tailored to different uses.

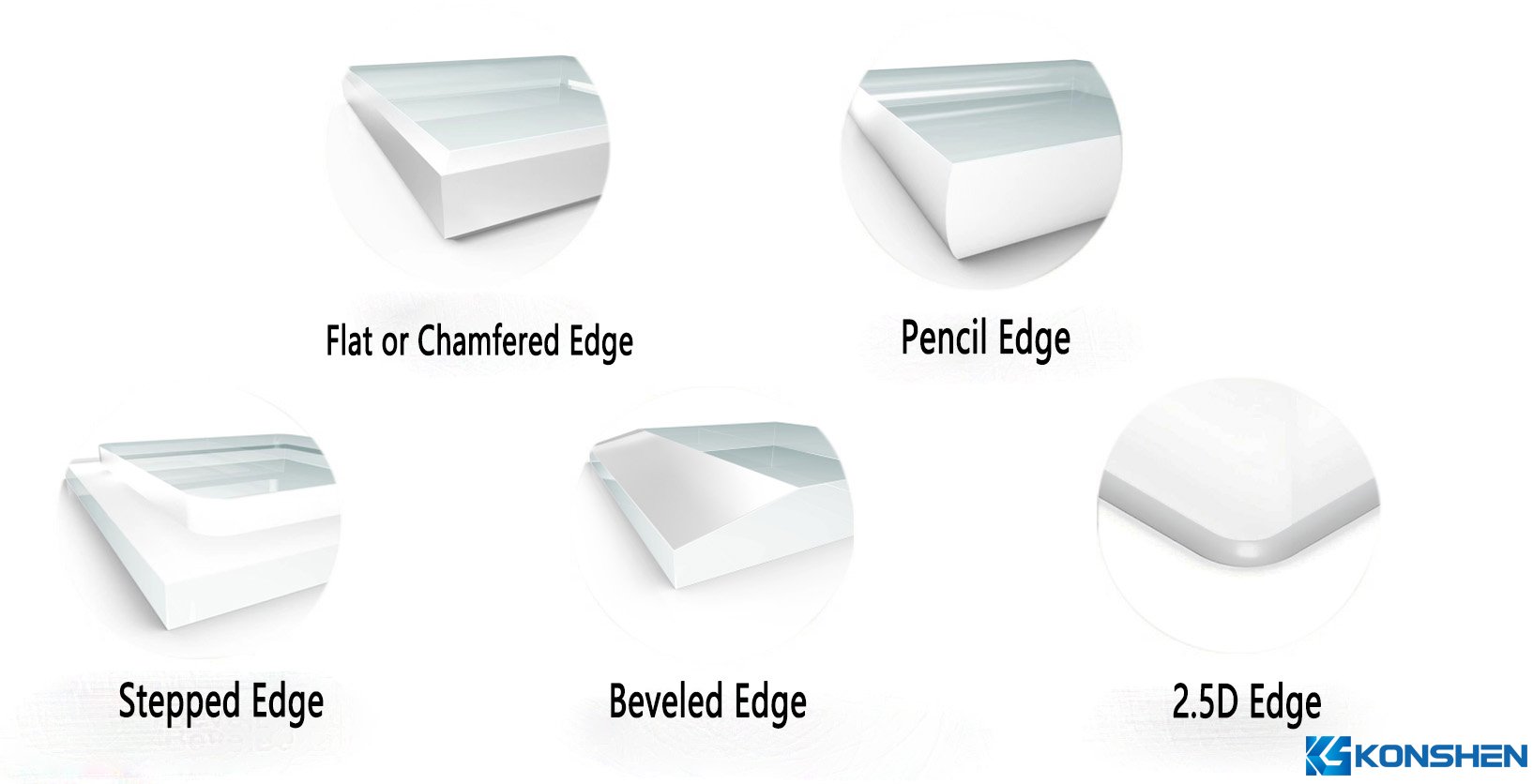

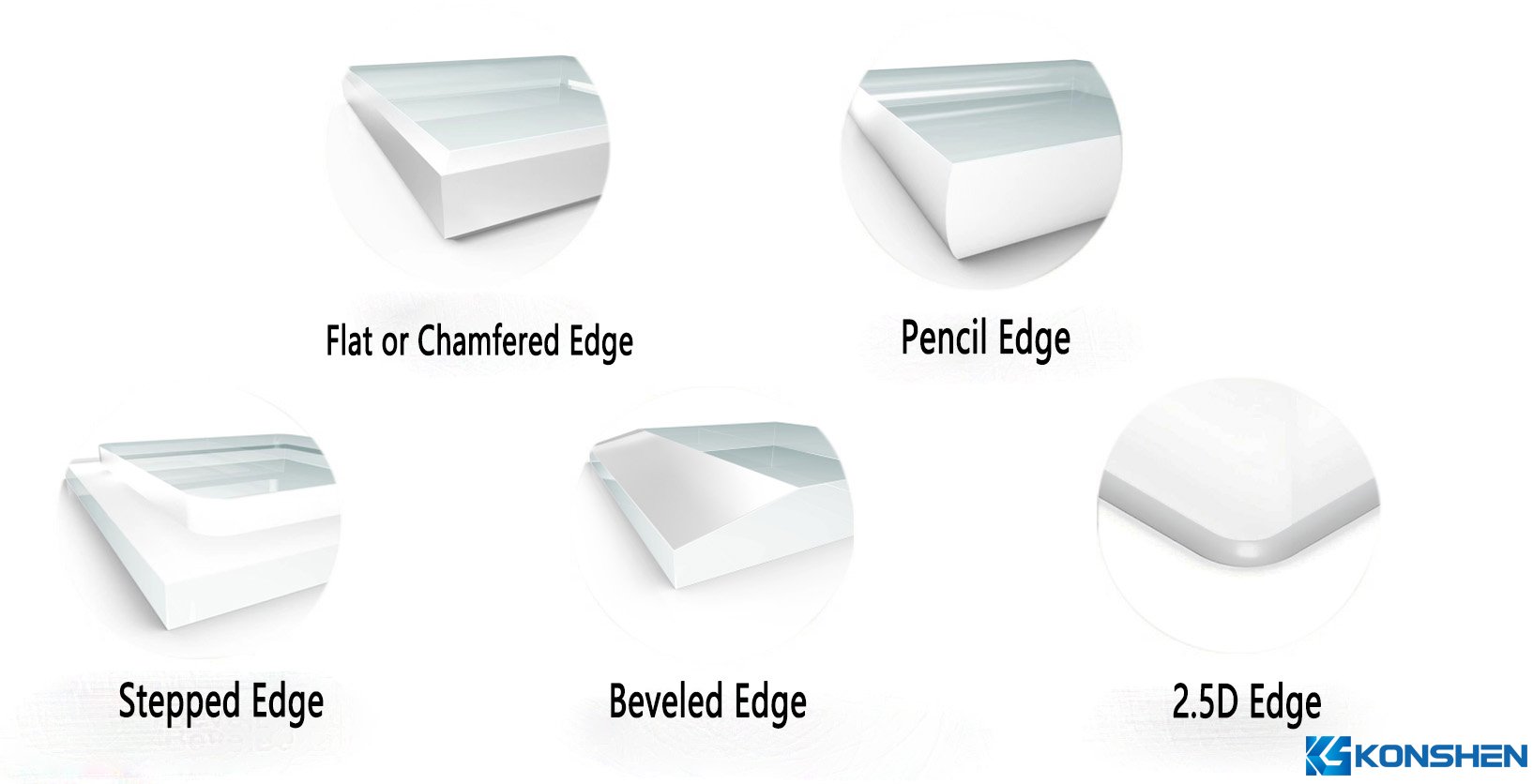

Let's take a closer look at five widely adopted edge treatment techniques in the glass industry, and how each serves different functional or aesthetic purposes.

1. Introduction of Common 5 Glass Edge Treatment

1.1 Flat Edge (Chamfered Edge)

This glass treatment method involves grinding the edge of the glass into a flat or slightly angled surface—often at 30° to 45°—and then polishing it for a matte or glossy finish. It's one of the most common choices for glass that will be seen and touched.

The flat or chamfered edge offers not just a clean, modern appearance, but also a stronger and more durable surface. This makes it a go-to solution for both decorative and functional applications where exposed edges must hold up over time.

1.2 Pencil Edge (C-Edge)

Pencil edging is a common glass edge treatment that creates a gently rounded profile,it often compared to the curve of a pencil or the letter “C.” Achieved with specialized curved grinding wheels, this finish can be matte or polished, depending on aesthetic preferences.

This smooth and rounded edge improves not just safety, but also the feel of the product. It’s frequently used in products designed to be handled frequently or installed in accessible areas.

1.3 2.5D Edge

A 2.5D edge treatment bridges the gap between flat and curved. Rather than being fully rounded, the edges are subtly curved—just enough to provide a smoother touch and improve the way light interacts with the surface.

This finish has become increasingly popular in consumer electronics, where comfort and sleek design are both essential. It not only enhances tactile experience but also gives devices a more seamless, high-end look.

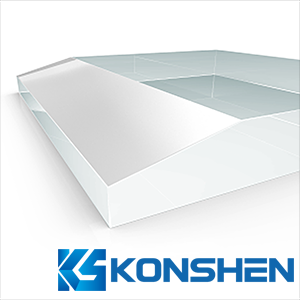

1.4 Beveled Edge

Beveled edging involves cutting the glass edge at an angle, usually wider and more dramatic than a standard chamfer. The bevel is then polished to enhance its reflective properties, often producing a prism-like effect that plays with light beautifully.

Though highly decorative, this finish also has structural benefits—it can help distribute impact more evenly across the glass surface, slightly improving resistance to edge breakage.

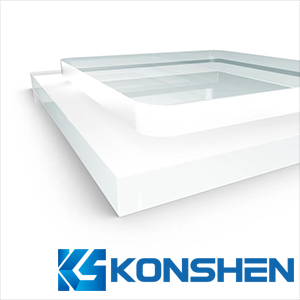

1.5 Stepped Edge

The stepped edge treatment is more complex, involving multi-level grinding to create precise layers or offsets along the edge. This technique is ideal when multiple glass pieces need to fit together seamlessly or when hardware must sit within specific recesses.

Stepped edges are particularly useful in custom glass applications where form and function must be carefully balanced, such as in lighting fixtures or curved structural glass.

2.Application Scenarios of Common Glass Edge Treatments

Each edge treatment method serves a specific purpose and is chosen based on the functional requirements, aesthetic goals, and safety standards of the final product. The six common glass edge finishes—Seamed, Flat/Chamfered, Pencil, 2.5D, Beveled, and Stepped—are widely used across various industries and applications.

|

Image

|

Type of Edge Treatment

|

Commom Application Scenarios

|

|

|

Flat Edge (Chamfered Edge)

|

Bathroom mirrors

Glass tabletops

Automotive side and rear windows

Flat display covers and home electronics

|

|

|

Pencil Edge (C-Edge) |

Consumer electronics

Household items

Kid-friendly products and safety glass

Decorative shelving and fixtures

|

|

Beveled Edge |

Framed decorative mirrors

Luxury displays and showroom furniture

Art glass and architectural features

|

|

Stepped Edge |

Lighting and lamp designs

Bespoke architectural projects

Designer furniture

Complex laminated glass builds

|

|

2.5D edge |

Smartphones and tablets

Smartwatches and wearable devices

Decorative architectural panels

Modern kitchen and household appliances

|

Choosing the appropriate edge treatment according to the specific application allows manufacturers to significantly enhance the safety, functionality, and visual appeal of glass products. This careful selection ensures better integration across a wide range of industries, including interior design, consumer electronics, architectural glazing, and industrial equipment manufacturing.

3.Why Edge Treatment Matters

While edge treatment might seem like a small part of the overall glass manufacturing process, it has far-reaching implications that go well beyond surface appearance. Properly finished edges help reduce the risk of cuts and injuries during handling, packaging, and installation—especially important when glass components are manually operated or exposed in end-use environments.

In addition to improving safety, edge treatment enhances the structural integrity of the glass. Untreated edges are more vulnerable to chipping, cracks, and stress accumulation, which can eventually lead to breakage under mechanical or thermal stress. A finished edge distributes stress more evenly and minimizes weak points, extending the service life of the product.

From an aesthetic perspective, a smooth and polished edge adds a refined, professional appearance that enhances the overall design—particularly in customer-facing applications such as display panels, furniture glass, and architectural installations. A high-quality edge finish can elevate even a simple piece of glass, contributing to a more premium and cohesive look.

Ultimately, edge treatment is not just about visual improvement—it’s a critical process that affects the safety, durability, and perceived quality of the final glass product. Whether for functional or decorative purposes, the right edge finish makes a meaningful difference.

4.Introduction of Edge Treatment Equipment

4.1 CNC edge grinding machine

CNC(Computer Numerical Control) edge grinding machine is usually equipped with multiple sets of grinding wheels.It uses a numerical control system to control the grinding wheel or diamond grinding tool to automatically process the glass edge. During this processing, the glass is fixed on the workbench, and the equipment drives the grinding head to move along the edge of the glass according to the preset program path to achieve a series of processes such as grinding, chamfering and polishing, effectively improving processing efficiency and edge quality.

CNC machining accuracy tolerance can be±0.2mm, capable of processing complex curves and special shape edges.

4.2 Precision engraving machine

Precision CNC engraving machine uses a high-speed spindle with a fine tool to achieve fine cutting of the glass edge and surface through multi-axis linkage. Compared with CNC edge grinding machines, precision engraving machines can process with higher precision(Accuracy up to 0.01mm) and smaller curvature radius, which are suitable for stepped edge grinding,various complex glass grooves and other glass projects with extremely high requirements for dimensional tolerance and edge finish.

Conclusion

Edge treatment is a vital consideration in glass design and engineering, directly affecting the safety, durability, and overall performance of glass components. Properly finished edges reduce stress concentrations and prevent micro-damage, extending product lifespan and reliability. Different edge profiles offer distinct functional and aesthetic benefits, enabling tailored solutions for diverse applications—from architectural facades to precision electronic displays. Understanding the characteristics and implications of various edge treatments helps technical and design professionals optimize glass integration and ensure seamless interaction between form and function in their projects.

Have technical requirements or drawings? Contact KS Glass for tailored edge treatment support!

Coated GlassElevate your projects with advanced coated glass solutions from KS Glass.

Coated GlassElevate your projects with advanced coated glass solutions from KS Glass. Cover GlassUpgrade your devices with our cover glass.

Cover GlassUpgrade your devices with our cover glass. Solar Panel GlassUpgrade your devices with our cover glass.

Solar Panel GlassUpgrade your devices with our cover glass. Glass MaterialDiscover the endless possibilities of working with large glass material.

Glass MaterialDiscover the endless possibilities of working with large glass material.