Contents:

Intrduction

1. Definition and Characteristics of Borosilicate Glass

1.1 Chemical Composition of Borosilicate Glass

1.2 Physical Properties of Borosilicate Glass

1.3 Comparative Analysis of Borosilicate Glass and High Borosilicate Glass

2. Temperature Resistance Advantages of Borosilicate Glass

2.1 Stability Under High-Temperature Conditions

2.2 Low Coefficient of Thermal Expansion and Its Impact

3. Processing and Manufacturing of Borosilicate Glass

3.1 Production Process of Borosilicate Glass

3.2 Impact of Precision Processing Technologies on Borosilicate Glass Performance

4. Why Borosilicate Glass Cannot Be Tempered

4.1 Basic Principle of Physical Tempering

4.2 Limitations Imposed by the Low Thermal Expansion of Borosilicate Glass

4.3 Impact of High Softening Point and Narrow Processing Window

4.4 Alternative Strengthening Approaches for Borosilicate Glass

5. Applications of Borosilicate Glass in Precision Equipment

5.1 Applications in Precision Optical Instruments

5.2 Applications in Semiconductor Manufacturing

5.3 Applications in Chemical Processing Equipment

5.4 Applications in Laboratory Instruments

5.5 Applications in Medical Equipment

Conclusion

Introduction

As precision equipment continues to evolve toward higher temperatures, higher power, and greater stability, the temperature resistance and long-term reliability of materials have become critical considerations in the design stage. In fields such as optical instruments, semiconductor manufacturing, laboratory equipment, and medical devices, materials are required not only to exhibit excellent mechanical strength but also to maintain dimensional stability and consistent performance under drastic temperature fluctuations or prolonged high-temperature conditions.

Among various glass materials, borosilicate glass has gradually become one of the indispensable materials in precision equipment due to its outstanding heat resistance, low coefficient of thermal expansion, and excellent chemical stability.

This article begins with an overview of the definition as well as the chemical and physical properties of borosilicate glass, systematically analyzes its advantages in temperature resistance, and further explores its application potential in the field of precision equipment.

Borosilicate glass is a type of specialty glass material primarily composed of silicon dioxide (SiO₂) and boron trioxide (B₂O₃). Typically, the SiO₂ content exceeds 70%, while the B₂O₃ content ranges from approximately 7% to 13%. Small amounts of alkali metal oxides (such as Na₂O and K₂O) and aluminum oxide (Al₂O₃) are also added to improve processability and structural stability.

Compared with conventional soda-lime glass, the higher proportion of B₂O₃ in borosilicate glass effectively modifies the glass network structure, forming a more stable and compact mixed silicon–oxygen and boron–oxygen network. This structure significantly reduces thermal expansion while enhancing thermal shock resistance and chemical inertness. As a result, borosilicate glass is able to maintain stable physical and chemical properties even under high temperatures, rapid temperature cycling, or corrosive environments.

From a physical performance perspective, the most prominent characteristics of borosilicate glass are its low coefficient of thermal expansion and excellent resistance to thermal shock. The typical linear thermal expansion coefficient of borosilicate glass is approximately 3.3 × 10⁻⁶ /K (20–300°C), which is significantly lower than that of ordinary glass materials. This property makes it less prone to cracking caused by internal thermal stress during rapid heating or sudden cooling.

In addition, borosilicate glass exhibits good high-temperature softening stability, with a softening point usually above 800°C, allowing it to maintain structural integrity over a wide temperature range. This characteristic is particularly critical for precision equipment that must operate for extended periods under high temperatures or in close proximity to heat sources.

In terms of optical and structural performance, borosilicate glass combines good light transmittance, relatively high surface hardness, and stable dimensional accuracy. These advantages enable it to serve not only as functional windows or protective components but also to meet application requirements that demand high optical consistency and tight assembly tolerances.

In practical applications and market communications, the terms borosilicate glass and high borosilicate glass are frequently used. However, there are notable differences between the two in terms of material composition, temperature resistance, and application positioning.

From a chemical composition standpoint, standard borosilicate glass contains a moderate level of B₂O₃, balancing heat resistance and processability while considering cost and forming efficiency. High borosilicate glass, by contrast, further increases the B₂O₃ content, resulting in a more stable glass network with a higher proportion of silicon–oxygen and boron–oxygen bonds. This leads to a significantly lower coefficient of thermal expansion and enhanced thermal shock resistance.

In terms of temperature resistance and thermal stability, high borosilicate glass offers more pronounced advantages. Under rapid thermal cycling or prolonged high-temperature operating conditions, it generates lower internal thermal stress and is less likely to develop cracks or structural instability. While standard borosilicate glass already outperforms soda-lime glass, its long-term stability may still be slightly inferior to that of high borosilicate glass in applications involving extreme temperature differentials or stringent reliability requirements.

From an application perspective, borosilicate glass is more commonly used in scenarios that require a certain level of heat resistance but involve relatively moderate operating conditions, such as industrial observation windows, general laboratory glassware, and protective glass for lighting systems. High borosilicate glass, on the other hand, is widely adopted in fields with stricter requirements for temperature precision, thermal shock resistance, and dimensional stability, including precision optical windows, semiconductor equipment viewports, high-end laboratory instruments, and medical diagnostic devices.

Overall, high borosilicate glass offers a higher performance ceiling and is the preferred material for high-end precision equipment. However, it also involves higher manufacturing costs and greater processing complexity. Therefore, in specific projects, a rational selection between borosilicate glass and high borosilicate glass should be made based on operating temperature, thermal cycling frequency, structural precision requirements, and cost considerations, in order to achieve an optimal balance between performance and economic efficiency.

The widespread adoption of borosilicate glass in high-end precision equipment is primarily attributed to its structural stability and predictability under high-temperature conditions. Compared with conventional glass materials, borosilicate glass not only withstands higher operating temperature ranges but also maintains long-term performance consistency under complex thermal cycling conditions. This reliability is of decisive importance for the stable operation of precision equipment.

Under elevated temperatures, glass materials typically face challenges such as structural softening, cumulative deformation, and the propagation of microcracks induced by thermal stress. Owing to its unique chemical composition and glass network structure, borosilicate glass effectively suppresses these failure mechanisms.

From a microstructural perspective, borosilicate glass is composed of a stable network formed by silicon–oxygen tetrahedra combined with boron–oxygen structural units. This composite network retains high bond energy and structural integrity even at elevated temperatures. As temperature increases, the degree of structural relaxation within the material remains relatively low, and the softening process occurs more gradually, reducing the likelihood of sudden deformation or abrupt degradation in mechanical properties. As a result, borosilicate glass is able to maintain good dimensional stability even when operating close to its long-term service temperature range.

In practical applications, borosilicate glass can typically be used stably for extended periods at temperatures of several hundred degrees Celsius. Even when exposed to higher temperatures for short durations, its structural integrity is not easily compromised. This characteristic is particularly critical for precision equipment operating near heat sources or under continuous thermal loads. For example, in semiconductor processing equipment or optical inspection systems, glass windows and protective components are often subjected to prolonged radiant heat and environmental temperature fluctuations. The high-temperature stability of borosilicate glass significantly reduces maintenance frequency and the risk of failure.

The coefficient of thermal expansion (CTE) is a key parameter for evaluating the dimensional change of a material during temperature variation and is one of the most important indicators in determining suitability for precision structures. One of the most prominent temperature resistance advantages of borosilicate glass lies in its extremely low and stable linear thermal expansion coefficient.

Typical borosilicate glass, especially high borosilicate glass, exhibits a linear thermal expansion coefficient of approximately

3.3 × 10⁻⁶ /K (20–300°C), which is significantly lower than that of conventional soda-lime glass. This means that under the same temperature differential, borosilicate glass undergoes much smaller dimensional changes, thereby substantially reducing internal stress concentration caused by thermal expansion and contraction.

A low coefficient of thermal expansion not only enhances the material's inherent resistance to thermal shock but also improves its structural compatibility with other materials such as metals, ceramics, or composite materials. In multi-material precision equipment, mismatches in thermal expansion behavior are often the primary causes of interfacial failure, seal degradation, or loss of assembly accuracy. Due to its mild and predictable thermal expansion behavior, borosilicate glass can be more easily integrated with surrounding structures through proper thermal matching design.

In addition, the low thermal expansion characteristic has a positive impact on optical stability and measurement accuracy. In optical windows, observation ports, or inspection channels, even minor temperature-induced deformation can lead to optical path deviation or focal length variation. By maintaining stable dimensions and geometry under thermal environments, borosilicate glass helps ensure consistent optical performance and reliable measurement accuracy across varying operating conditions.

The excellent temperature resistance of borosilicate glass is not only derived from its chemical composition and structural characteristics, but is also closely related to its production methods and subsequent precision processing. Well-designed manufacturing processes and advanced machining techniques can preserve the intrinsic properties of the material while further enhancing its reliability in precision equipment applications.

The superior thermal performance of borosilicate glass is achieved through carefully controlled melting and forming processes. During production, raw materials such as silica (SiO₂), boron trioxide (B₂O₃), and other functional oxides are precisely proportioned and melted at high temperatures to form a homogeneous glass melt. The melting process requires strict control of temperature and composition to ensure uniform distribution of boron within the glass network, which is critical for achieving low thermal expansion and high thermal stability.

The superior thermal performance of borosilicate glass is achieved through carefully controlled melting and forming processes. During production, raw materials such as silica (SiO₂), boron trioxide (B₂O₃), and other functional oxides are precisely proportioned and melted at high temperatures to form a homogeneous glass melt. The melting process requires strict control of temperature and composition to ensure uniform distribution of boron within the glass network, which is critical for achieving low thermal expansion and high thermal stability.

After melting, the glass is formed through processes such as float forming, tubing, pressing, or drawing, depending on the intended product form. Controlled cooling and annealing are then applied to relieve internal stresses generated during forming. Proper annealing is particularly important for borosilicate glass, as residual stress can adversely affect thermal shock resistance and long-term dimensional stability. Through optimized production control, borosilicate glass can achieve a stable internal structure that provides a solid foundation for subsequent precision processing.

In precision equipment applications, borosilicate glass typically undergoes multiple machining processes, including cutting, edge grinding, drilling, polishing, and surface treatment. Although these processes do not alter the chemical composition of the glass, they have a significant influence on surface quality, stress distribution, and final service performance.

Precision cutting and grinding ensure dimensional accuracy and assembly consistency. However, improper control of processing parameters may introduce microcracks at edges or drilled holes, which can reduce thermal shock resistance. For high-end applications, low-stress machining methods are therefore commonly employed, along with fine edge finishing or chamfering, to minimize stress concentration and the risk of crack initiation.

Precision cutting and grinding ensure dimensional accuracy and assembly consistency. However, improper control of processing parameters may introduce microcracks at edges or drilled holes, which can reduce thermal shock resistance. For high-end applications, low-stress machining methods are therefore commonly employed, along with fine edge finishing or chamfering, to minimize stress concentration and the risk of crack initiation.

High-quality polishing not only enhances the optical performance of borosilicate glass but also contributes to improved long-term stability under high-temperature conditions. Smooth and uniform surfaces reduce the likelihood of crack initiation and improve reliability under repeated thermal cycling. In certain applications, functional surface coatings may also be applied to further enhance wear resistance, anti-contamination properties, or optical control performance.

Overall, the final performance of borosilicate glass in precision equipment is the result of the combined effects of intrinsic material properties and processing quality. Through scientifically designed manufacturing processes and advanced precision machining techniques, the temperature resistance advantages of borosilicate glass can be fully realized, providing stable and reliable material support for high-end equipment.

In the field of glass processing, tempering is widely regarded as an effective method for enhancing glass strength and safety. However, unlike soda-lime glass or certain aluminosilicate glasses, borosilicate glass generally cannot be effectively strengthened through conventional physical tempering processes in practical engineering applications. This limitation is not due to processing constraints, but rather is determined by the inherent physical properties of the material itself.

Physically tempered glass is produced by heating the glass to near its softening point, followed by rapid and uniform cooling. This process creates compressive stress on the glass surface and tensile stress within the interior, thereby significantly improving bending strength and impact resistance.

The core prerequisites of this process are:

The glass must exhibit sufficient thermal deformation capability during the heating stage.

A significant temperature gradient must be established between the surface and the interior during cooling.

Only when these conditions are met can a stable and effective stress distribution be formed within the glass through the tempering process.

Due to its extremely low coefficient of thermal expansion, borosilicate glass undergoes much smaller volumetric changes during heating and cooling compared with conventional soda-lime glass. As a direct consequence, it is difficult to establish a sufficiently large temperature differential and stress gradient between the surface and the interior during physical tempering.

In other words, even when standard tempering temperatures and cooling rates are applied, borosilicate glass cannot readily develop a stable surface compressive stress layer. The resulting tempering effect is extremely limited and, in many cases, negligible. In some situations, forcibly applying a tempering process may instead introduce non-uniform residual stresses, ultimately reducing the overall reliability of the material.

In addition to its low coefficient of thermal expansion, borosilicate glass is characterized by a relatively high softening point and a narrow viscosity stability range. This means that higher temperatures are required during heating to reach a state suitable for tempering. However, once temperature control becomes imprecise, the material is more prone to forming risks or structural instability.

By comparison, soda-lime glass offers a much wider processing window, making it more suitable for large-scale physical tempering production. In engineering practice, the combination of a high softening point and a narrow tempering window makes it difficult for borosilicate glass to achieve stable and repeatable strengthening effects using conventional tempering equipment.

Although borosilicate glass is not suitable for physical tempering, its reliability in practical applications does not depend on tempering processes. On one hand, the inherently excellent thermal shock resistance of borosilicate glass provides a high safety margin under high-temperature and thermal cycling conditions. On the other hand, in certain applications, overall performance can be enhanced through the following approaches:

Structural design optimization: Reducing the risk of fracture through appropriate thickness selection, edge chamfering, and stress-relief design.

High-quality precision machining: Minimizing microcracks and edge defects to improve actual mechanical strength.

Surface treatment or functional coatings: Enhancing wear resistance or functional performance without introducing additional thermal stress.

Therefore, in high-end precision equipment, borosilicate glass primarily relies on its intrinsic material stability combined with sound engineering design to meet application requirements, rather than on tempering processes to increase strength.

Owing to its excellent temperature resistance, low coefficient of thermal expansion, and long-term stability in both physical and chemical properties, borosilicate glass is widely used as a key structural or functional material in various types of precision equipment. In systems that are sensitive to temperature fluctuations, operate under harsh environments, or demand extremely high precision, borosilicate glass is often a core material choice for ensuring reliability and consistency.

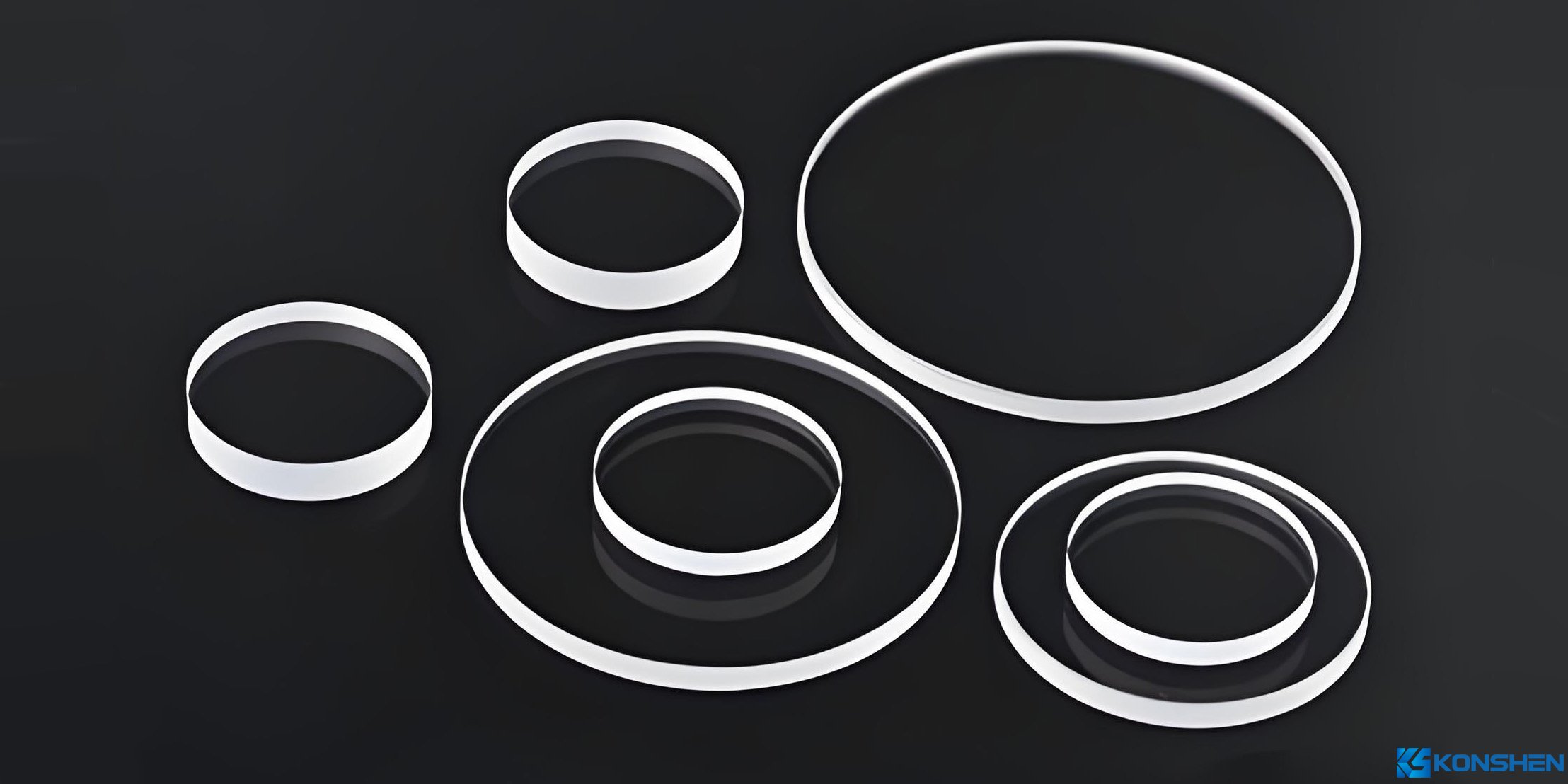

In precision optical instruments, the thermal stability of materials directly affects optical path accuracy and imaging quality. Thanks to its low thermal expansion and good optical homogeneity, borosilicate glass is commonly used for optical windows, observation ports, protective cover glasses, and auxiliary optical components.

During actual operation, optical equipment is often subject to heat generated by light sources or changes in ambient temperature. If the glass material undergoes noticeable deformation when heated, it may lead to optical axis deviation, focal length variation, or cumulative measurement errors. Borosilicate glass maintains stable geometry and surface flatness under temperature variations, helping ensure consistent optical performance across different operating conditions. This advantage has led to its widespread use in spectrometers, imaging inspection systems, laser equipment, and high-precision measurement instruments.

Semiconductor manufacturing places extremely high demands on materials in terms of temperature resistance, cleanliness, and chemical stability. Due to its structural stability under high-temperature conditions and excellent corrosion resistance, borosilicate glass is frequently used for equipment observation windows, process chamber viewports, and isolation or protective components.

During wafer fabrication and packaging/testing processes, equipment often undergoes frequent thermal cycling and localized high-temperature exposure. Borosilicate glass effectively resists crack propagation induced by thermal stress under such conditions, reducing the risk of downtime caused by material failure. Its low thermal expansion also helps maintain stable assemblies with metal or ceramic components, ensuring long-term equipment reliability and process consistency.

In chemical equipment, materials must not only withstand high temperatures but also exhibit strong chemical inertness to resist acids, alkalis, and other corrosive media. In this field, borosilicate glass is commonly used for reactor observation windows, process monitoring windows, and high-temperature pipeline viewports.

Chemical processes are typically accompanied by temperature fluctuations and aggressive chemical environments, under which ordinary glass is prone to stress corrosion or thermal shock failure. With its stable glass network structure, borosilicate glass maintains good transparency and mechanical integrity even under the combined effects of high temperature and corrosive media, providing reliable visual monitoring of equipment operating conditions.

Laboratory instruments represent one of the most mature application areas for borosilicate glass. From traditional laboratory glassware to modern analytical equipment, borosilicate glass is widely used for heating vessels, observation windows, sample protection covers, and structural support components.

During laboratory operations, components often experience repeated heating, cooling, and rapid temperature changes. The excellent thermal shock resistance of borosilicate glass effectively prevents breakage caused by sudden temperature changes, improving experimental safety and extending equipment service life. In addition, its dimensional stability helps ensure repeatability of experimental conditions, meeting the stringent requirements for accuracy and consistency in research and testing.

In the medical equipment sector, material reliability, safety, and long-term stability are of paramount importance. With its good temperature resistance, chemical stability, and controllable processing precision, borosilicate glass is commonly used in diagnostic equipment observation windows, optical inspection windows, and functional components exposed to high-temperature sterilization environments.

Many medical devices undergo high-temperature sterilization or thermal treatment during use or maintenance. Borosilicate glass resists performance degradation under such conditions and maintains stable optical and structural properties, helping ensure safety and accuracy throughout long-term operation. As a result, its application continues to expand in medical imaging systems, analytical instruments, and high-end medical devices.

As precision equipment continues to advance toward higher operating temperatures, higher power levels, and greater stability, the temperature resistance and long-term reliability of materials have become critical factors in system design. With its low coefficient of thermal expansion, excellent resistance to thermal shock, and stable structural characteristics under high-temperature conditions, borosilicate glass demonstrates clear advantages across a wide range of precision equipment applications.

Although borosilicate glass is not suitable for strengthening through conventional physical tempering processes, its engineering value does not rely on tempering for performance enhancement. Through appropriate material selection, optimized structural design, and high-quality precision machining, borosilicate glass has been widely adopted in optical instruments, semiconductor equipment, chemical processing systems, laboratory instruments, and medical devices, where it continues to provide reliable and consistent performance in demanding operating environments.

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us