Contents:

1. Overview of Mainstream Cover Glass Materials for Smart Panels

1.1 Soda Lime Glass

1.2 Borosilicate Glass

1.3 Tempered Glass

1.4 Other Emerging Materials

2. Safety Advantages of Tempered Glass

2.1 Superior Impact Resistance

2.2 Safe Breakage Morphology

2.3 Reliable Thermal Stability

2.4 Long-Term Durability

3. Practical Selection Criteria for Tempered Glass in Smart Cover Panels

3.1 Thickness Matching Based on Device Type

3.2 Strengthening Process Selection

3.3 Surface Treatment Optimization

3.4 Compliance with International Standards

3.5 Extreme Environment Adaptation

4. Global Market Application and Future Trends

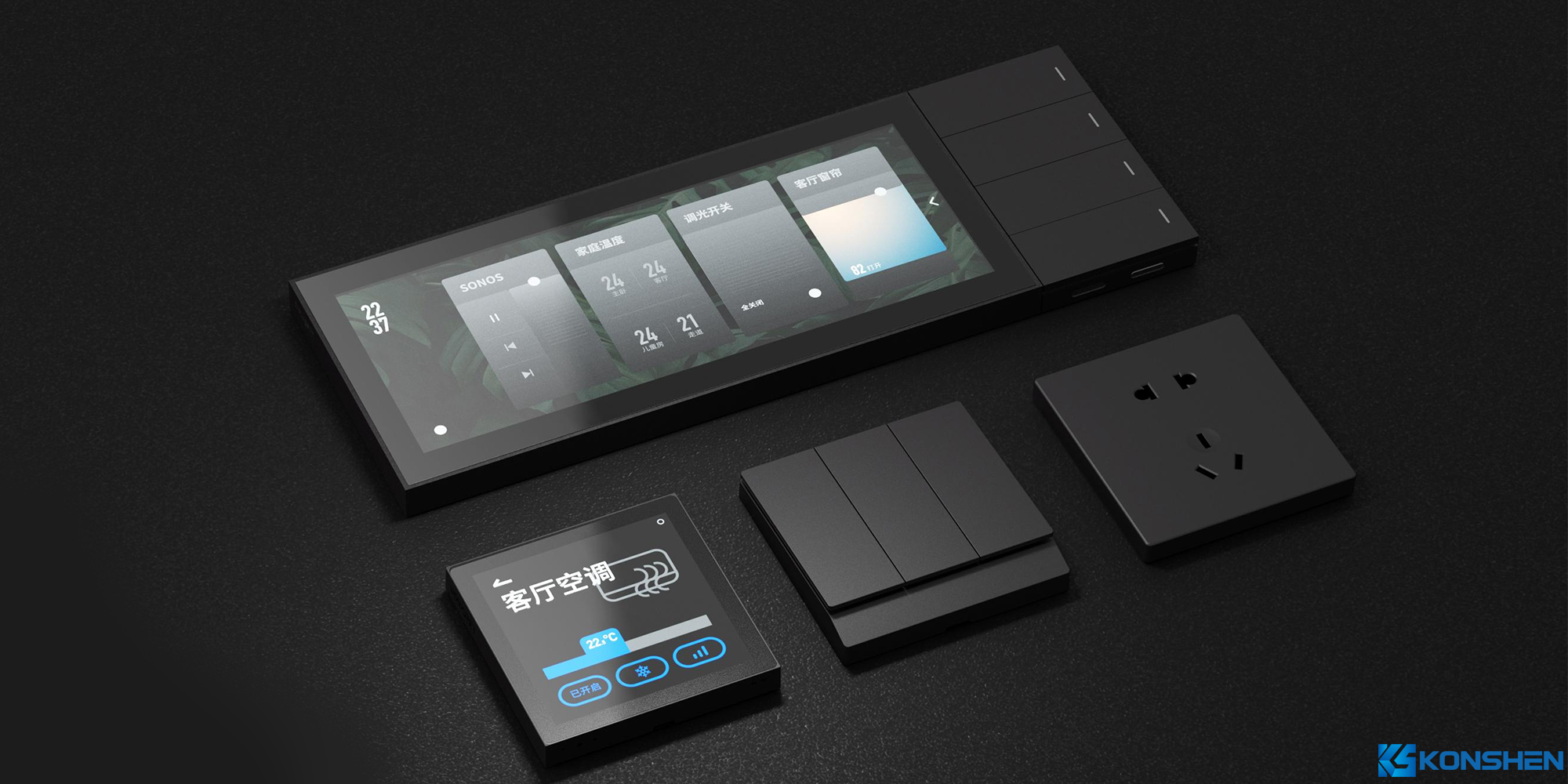

Smart cover panels have become integral components in modern electronic devices, spanning smartphones, smart home controls, and automotive displays. The safety performance of their cover glass directly impacts user experience and device reliability. With the global smart device market expanding at a steady pace—driven by over 85% of adults worldwide owning smartphones—material selection for cover glass has evolved from a purely functional consideration to a critical safety priority. Among various options, tempered glass stands out as the preferred material for smart cover panels due to its superior mechanical strength, controlled breakage behavior, and adaptability to diverse operating environments.

As the most basic glass material, soda lime glass is composed of silica, sodium oxide, and calcium oxide. It features low production costs and high transparency, with light transmittance exceeding 90%. However, its mechanical properties are inferior, with a bending strength of only 50-70 MPa and impact resistance that fails to meet the safety requirements of smart cover panels. Soda lime glass breaks into large, sharp fragments when subjected to impact, posing significant safety hazards. Currently, it is rarely used in smart device cover panels, limited primarily to low-cost, non-interactive decorative components.

Borosilicate glass is manufactured by adding boron oxide to the glass composition, resulting in an extremely low thermal expansion coefficient (approximately 3.3 x 10⁻⁶/K). This material excels in thermal shock resistance, capable of withstanding rapid temperature changes of up to 500°C without cracking, making it ideal for high-temperature environments such as laboratory equipment and high-end cookware. However, its impact resistance is only moderately improved compared to soda lime glass, and it still breaks into sharp fragments. Additionally, higher production costs restrict its widespread application in mainstream smart cover panels.

Tempered glass is produced by heating ordinary glass to approximately 700°C and then subjecting it to rapid uniform cooling. This process creates a compressive stress layer on the surface and tensile stress inside the glass, significantly enhancing its mechanical properties. The bending strength of tempered glass reaches 150-250 MPa, 4-5 times that of ordinary glass, while its impact resistance is increased by 5-10 times. A key safety feature is its breakage behavior: when shattered, it fragments into small, rounded particles without sharp edges, minimizing injury risks. Two primary types dominate the market: physically tempered glass, suitable for thicker panels (above 2mm), and chemically strengthened glass, which uses ion exchange technology to achieve strengthening effects for ultra-thin panels (0.2-5.0mm), making it ideal for smart devices. Critical performance indicators for qualified tempered glass include surface compressive stress ≥90MPa, stress layer depth ≤35MPa, and fragment count ≥40 particles per 50mm×50mm area with maximum fragment weight ≤50g, as specified by international testing standards.

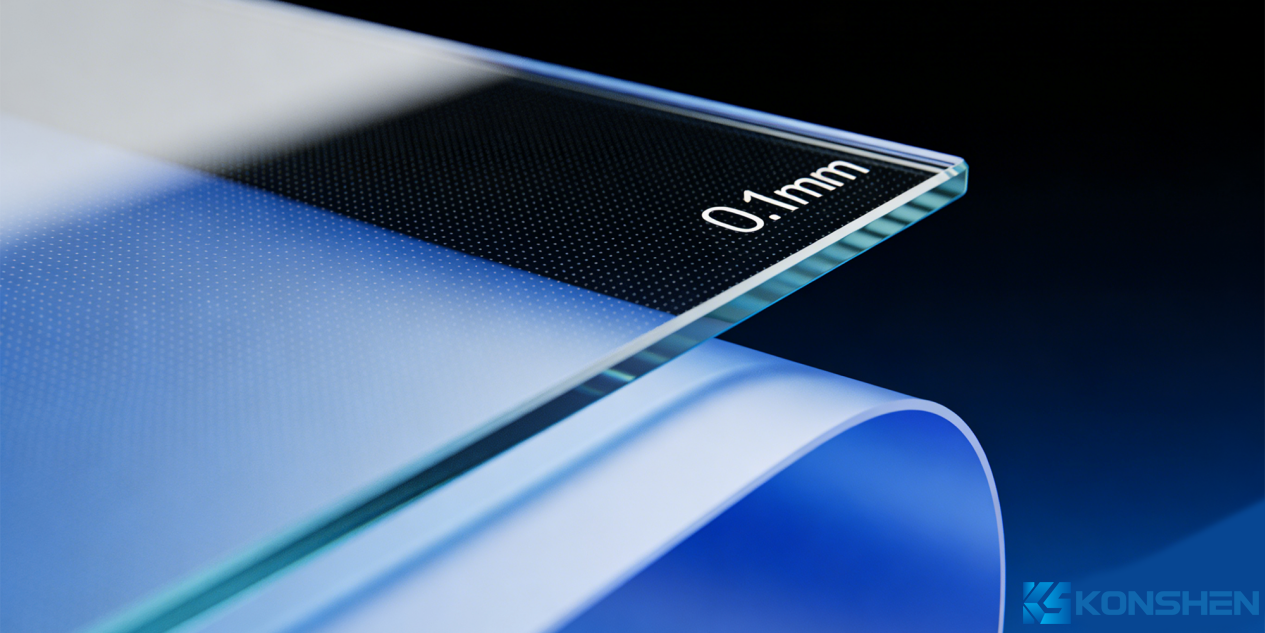

Sapphire glass, composed of aluminum oxide crystals, offers exceptional hardness (second only to diamond) and scratch resistance. However, its high brittleness, poor impact resistance, and exorbitant production costs (5-10 times that of tempered glass) limit its application to high-end, niche products such as luxury watch faces. Flexible glass, a recent innovation, exhibits bendability but remains in the developmental stage with inadequate mechanical stability for mass-produced smart cover panels. Ultra-thin glass (UTG), a specialized type of tempered glass, has emerged as a key material for foldable devices, enabling repeated bending with minimal fatigue.

Impact resistance is a core safety metric for smart cover panels, as devices are frequently at risk of accidental drops. According to testing data from the China Building Glass and Industrial Glass Association, chemically strengthened tempered glass achieves an impact resistance 5-10 times that of ordinary soda lime glass. In standardized drop tests (1.5-meter height onto concrete), tempered glass cover panels for smartphones exhibited a 92% survival rate, compared to 18% for soda lime glass and 45% for borosilicate glass. International testing standards further validate this performance: under the ECE R43 standard for automotive glass, tempered glass withstands 1040g steel ball impacts from 1m height without penetration, maintaining over 80% residual strength. Global smartphone manufacturers prioritize this performance: 78% of OEMs prefer chemically strengthened ultra-thin glass for its enhanced drop protection, with flagship models such as those using Corning Gorilla Glass (a type of chemically strengthened tempered glass) dominating the premium market with a 48% share of the global smartphone cover glass segment. Specialized tempered glass variants like SCHOTT Xensation α, made from lithium aluminum borosilicate (LABS), offer 100% improved drop resistance on rough surfaces compared to traditional aluminosilicate glass, as validated by Knoop diamond indenter tests.

The breakage behavior of glass directly affects user safety. Traditional glass breaks into large, sharp shards that can cause lacerations, while tempered glass fragments into small, rounded particles (typically 5-8mm in size) due to its internal stress distribution. A study published in the Journal of Materials Science & Technology confirmed that tempered glass breakage produces no acute angles, reducing injury risk by over 80% compared to soda lime glass. This property aligns with international safety standards such as ASTM F1233 for shower glass and AS/NZS 4667 for scratch resistance, which mandate controlled fragmentation. For smart cover panels, compliance with these standards ensures that even in breakage scenarios, users are protected from severe lacerations. This property has made tempered glass the mandatory material for automotive windows and building safety glass, and its adoption in smart cover panels aligns with global consumer safety expectations.

Smart devices generate heat during operation, and cover glass must withstand temperature fluctuations without cracking. Tempered glass exhibits excellent thermal stability, capable of enduring temperature changes of approximately 220°C—2-3 times that of ordinary glass. In rigorous thermal shock tests, it withstands cyclic temperature changes from 170°C to 20°C at least 3 times without bursting or strength degradation. This performance ensures resistance to thermal shock from rapid environmental temperature shifts or device overheating. For example, tempered glass used in automotive display panels maintains structural integrity even in extreme temperature ranges of -40°C to 85°C, a common requirement for vehicle electronics. In contrast, borosilicate glass, while superior in extreme thermal resistance, lacks the impact resistance required for portable smart devices, making it unsuitable for mainstream cover panel applications.

Smart cover panels require sustained performance over extended use. Testing by 360 Research Reports shows that tempered glass cover panels maintain structural integrity after over 50,000 friction cycles, significantly outperforming soda lime glass (which fails after 5,000 cycles). Additionally, the compressive stress layer on tempered glass surfaces enhances scratch resistance, with a Mohs hardness rating of 6-7, sufficient to resist daily scratches from keys or coins. UV aging tests simulating 10 years of exposure confirm that tempered glass retains over 97% of its original light transmittance, with a yellowing index ΔE ≤1.5. This durability reduces maintenance costs and extends device lifespan, a key factor driving the 47% surge in demand for durable cover glass over the past five years. For foldable devices, specialized UTG tempered glass such as SCHOTT UTG achieves 500,000 folding cycles without failure, as certified by TÜV Rheinland, enabling the longevity of foldable smartphone displays.

Ultra-thin chemically strengthened tempered glass (0.2-1.1mm) is preferred for portable devices such as smartphones and smartwatches, balancing light weight and durability. For foldable devices, 0.1-0.2mm UTG tempered glass is essential to achieve minimal bending radii, with SCHOTT UTG variants as thin as 16μm available for specialized applications. For larger devices like tablet computers and smart home control panels, 1.1-2.0mm tempered glass provides enhanced structural stability. Automotive display panels, which face harsher operating environments, typically use 2.0-4.0mm physically tempered glass to withstand impact and vibration, with thickness deviation controlled within ±0.3mm to ensure optical uniformity.

Chemically strengthened glass is ideal for ultra-thin panels, as it avoids the deformation issues associated with physical tempering. Its deep compression layer (exceeding 40μm) ensures superior durability, making it the material of choice for 92% of smartphone front covers and 68% of rear covers. The ion exchange process used in chemical strengthening results in uniform stress distribution, critical for ultra-thin applications. Physical tempering is suitable for thicker panels, offering higher production efficiency and lower costs for large-area applications such as smart home wall panels. It is particularly effective for panels requiring high thermal stability, as the rapid cooling process enhances resistance to temperature fluctuations.

Surface coatings enhance the performance of tempered glass cover panels. Anti-fingerprint coatings reduce oil adhesion, improving user experience, and are now standard on 61% of mid-range smartphones, with durability tested to withstand 10,000 wipes without degradation. Anti-glare coatings improve visibility in bright environments, critical for outdoor-facing devices like automotive displays, achieving a haze value ≤0.5% while maintaining high light transmittance. For medical or food industry smart panels, antimicrobial coatings complying with ISO 22196 standards achieve 99% bacterial inhibition, essential for hygiene-critical applications. Edge treatment is also critical: polished edges reduce stress concentration, with edge impact resistance tested to withstand 500g drop impacts without excessive crack propagation (crack length ≤50mm).

Tempered glass materials must comply with relevant international standards to ensure safety. Key standards include ISO 12543-1 for architectural glass (applicable to large smart panels), ASTM C1048 for tempered glass performance, and ECE R43 for automotive applications. For electronic touch panels, surface roughness requirements (Ra ≤0.01μm) and dielectric strength (>15kV/mm) must be met to ensure touch sensitivity. Marine and coastal applications require additional salt spray corrosion resistance, with 72-hour salt spray tests showing no pitting. These standards specify requirements for impact resistance, breakage morphology, and thermal stability, providing a benchmark for material selection. Manufacturers should prioritize materials certified by accredited third-party testing bodies to ensure compliance.

For devices used in extreme environments, specialized tempered glass variants are required. High-temperature environments (e.g., industrial control panels) demand tempered glass with enhanced heat resistance, capable of withstanding continuous operating temperatures up to 300°C. Low-temperature environments (e.g., outdoor smart meters in cold climates) require glass with improved resistance to thermal shock, withstanding -40°C to 85°C cyclic changes without cracking. Coastal or marine environments require tempered glass with anti-corrosion coatings to resist salt fog, with chemical stability tested via 5% HCl immersion for 24 hours showing weight loss ≤0.1mg/cm². For high-altitude applications, pressure-resistant tempered glass with bending strength ≥120MPa ensures structural integrity under low atmospheric pressure.

Tempered glass has established dominance in the global smart cover glass market, driven by its safety advantages and technological maturity. The global cover glass market reached USD 7.91 billion in 2024 and is projected to grow at a CAGR of 7.71% to USD 14.34 billion by 2032. The smartphone segment accounts for the largest share, with the global smartphone cover glass market estimated at USD 1.54 billion in 2025 and expected to reach USD 1.73 billion by 2034. Asia-Pacific leads the market with a 54% share, followed by North America (21%) and Europe (18%), with major manufacturers including Corning (28% market share), AGC (17%), and SCHOTT focusing on tempered glass innovation.

Sustainability has become a key focus for global manufacturers. AGC's Recycle Glass program collects end-of-life glass waste from construction and renovation projects, processing it into cullet for reuse in tempered glass production. This approach reduces CO₂ emissions by lowering melting energy requirements and replaces virgin raw materials, with AGC providing customers with certificates verifying resource savings and emission reductions. 56% of 2024 smartphone models already adopt recyclable tempered glass materials, reflecting the industry's shift toward circular economy principles.

Future trends in tempered glass for smart cover panels include three key directions: ultra-thin and lightweight design, with thickness expected to decrease below 0.5mm to meet the demands of foldable devices; multifunctional integration, combining anti-fingerprint, anti-glare, and antimicrobial properties with conductive coatings for touch-sensitive applications; and advanced strengthening technologies, such as laser tempering, which enables precise stress distribution for complex shapes. Flexible tempered glass innovations will expand application scenarios to wearable devices and curved automotive displays, further solidifying its position as the safe material of choice for smart cover panels.

In the evolving landscape of smart devices, the safety and reliability of cover glass directly define user trust and product competitiveness. By adhering to application-specific selection criteria—matching thickness to device type, optimizing strengthening processes and surface treatments, complying with international standards, and adapting to extreme environments—manufacturers can fully leverage the safety advantages of tempered glass. This ongoing evolution reinforces tempered glass's status as the cornerstone of smart cover panel safety worldwide, underpinning the reliability of the smart devices that integrate seamlessly into modern life.

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us