From ancient civilizations to modern industries, glass has played an essential role throughout human history. It is not only a key material in architecture and decoration but also the core foundation of modern technology, display, photovoltaic, and electronics industries.Behind every glass product lies the same starting point— the glass substrate. As the base material for all deep-processed glass (such as tempered glass, coated glass, and cover glass), its composition and manufacturing process determine the performance and quality of the final product.

This article begins with the origin of glass, providing a systematic analysis of the evolution of raw glass materials, their main classifications, manufacturing methods, quality inspection standards, leading global brands, and future technological trends. It aims to help B2B buyers and industry professionals understand the core value of glass substrates in modern manufacturing.

The origin of glass can be traced back to ancient Egypt and Mesopotamia around 3500 BCE.

Archaeological evidence shows that as early as 3500–3000 BCE, people in Mesopotamia had already begun to use natural glass. It is believed that the earliest glass was accidentally formed when natural alkali and silica sand fused under high temperatures, producing colored or semi-transparent natural glass — obsidian being the most common example.

Ancient Egyptians are widely recognized as the first glassmakers in history. Around 3000 BCE, Egyptian artisans deliberately began smelting glass by mixing sand, soda ash, and limestone at high temperatures to produce colorful beads, ornaments, and small containers. These early handmade glasses were created using molding and core-forming techniques, marking the birth of artificial glass. Archaeological discoveries from tombs and excavation sites have confirmed these findings.

The early Egyptian mastery of glassmaking laid the foundation for later innovations such as glassblowing and decorative glass craftsmanship.

Following the invention of the core-forming and casting methods in ancient Egypt, craftsmen used clay molds to shape molten glass along the mold’s surface and later removed the mold once the glass cooled — a time-consuming and expensive process.

It wasn’t until the 1st century BCE that Syrian artisans invented the glassblowing technique, using a hollow iron tube to blow air into softened molten glass, forming hollow vessels. This innovation enabled the mass production of thin and lightweight glassware in various shapes, making glass more accessible to ordinary people. It also laid the groundwork for the widespread adoption of glass across the Roman Empire.

In 64 BCE, Roman General Pompey conquered Syria and brought glassblowing technology back to Rome. After the conquest of Egypt in 30 BCE, the Romans combined Egypt's traditional casting techniques with Syria's glassblowing technology to develop the mold-blown glass process. This allowed for more standardized and diverse glass shapes.

The Romans also developed decolorization techniques that removed green impurities, resulting in clearer glass. Their optimization and large-scale promotion of these technologies led to the industrialization of early glass production across the Mediterranean.

By the Middle Ages, glassmaking centers shifted to Venice, Italy. Venetian craftsmen invented Venetian crystal glass, renowned for its clarity and brilliance among European nobility. Meanwhile, stained glass art flourished, with churches and cathedrals using colored glass windows for decoration and symbolism.

By the late 17th and early 18th centuries, Europe had already developed mature glass smelting and forming techniques. Venetian crystal glass and French mirror glass were famous examples. However, production still relied heavily on skilled craftsmen, limiting output and keeping costs high.

The Industrial Revolution transformed the industry. Britain pioneered the use of coal instead of wood to heat crucible furnaces. Coal’s higher and more stable burning temperature improved glass purity and consistency while reducing energy costs.

This fuel revolution laid the energy foundation for glass mass production. With the advent of steam engines, coal-fired furnaces, and mechanical drives, glass manufacturing entered a new era of mechanization and large-scale production.

The Industrial Revolution also expanded glass applications into new scientific and optical fields. The demand for precision glass drove innovation in material composition and performance:

In the 1880s, SCHOTT AG (Germany) developed borosilicate glass, which became essential for optical instruments, chemical ware, and later electronic components.

French and British researchers improved lead glass and soda-lime glass formulas, achieving higher transparency and more stable refractive indices.

By the late 19th century, glass was indispensable for light bulbs, optical lenses, laboratory equipment, microscopes, and early cameras. Standardized production lines emerged across Europe and the United States, making glass one of the most critical industrial base materials alongside steel and cement.

This mass-production revolution not only changed how glass was made but also redefined its role in society and industrial development.

In 1688, French inventor Louis Lucas de Nehou of Saint-Gobain developed the cast plate glass process, which involved pouring molten glass onto a metal table and flattening it mechanically, followed by manual grinding and polishing. This allowed the creation of large, flat glass sheets for the first time — marking the shift from artisanal to semi-mechanized industrial production.

In the early 19th century, Britain developed the Cylinder Blown Sheet technique, in which a blown glass cylinder was cut and flattened into sheets. It became the mainstream method for architectural window glass production during that period.

At the end of the 19th century, American engineer Michael J. Owens invented the fully automatic bottle-blowing machine, which replaced manual glassblowing entirely and increased productivity dozens of times over. This was the first fully automated glass production in history and laid the foundation for industrial glass container manufacturing. The concept of float glass also began to take shape around this time.

Belgian engineer Émile Fourcault invented the Fourcault process in the late 19th to early 20th century. Molten glass was continuously drawn upward through a slot to form long, flat sheets, later cooled and trimmed. This method improved output and dimensional control, representing the early continuous production of flat glass.

Later, American engineer Colburn enhanced the Fourcault process by improving control over drawing speed and temperature gradient, producing glass with more uniform thickness and higher stability. The process became widely used for windows, mirrors, and industrial plates, signifying the maturity of mechanized continuous production in glassmaking.

According to Grand View Research (2024), the global flat glass market was valued at USD 311.4 billion in 2024 and is expected to reach USD 404.8 billion by 2030, with a CAGR of 4.6%.

Market growth is primarily driven by demand from construction, automotive, and electronic display industries.

Regional insights:

Asia-Pacific holds about 45.4% of the global market, led by China, India, and Japan.

Europe and North America show slower growth but rising demand for high-performance optical and energy-efficient glass, pushing the industry toward higher value-added products.

With the expansion of photovoltaic glass, large-format display glass, and high-performance architectural glass, the global market is projected to maintain steady growth.

Modern manufacturing has reached a high level of automation and continuous processing, dominated by techniques such as Down Draw, Float, and Overflow processes — each with distinct advantages in formability, thickness control, and surface flatness. Detailed comparisons will be presented in the next chapter.

Raw glass materials refer to base glass sheets that have not yet undergone deep processing, such as cutting, tempering, coating, or printing.

These materials are produced through melting, forming, and annealing processes to create glass substrates that serve as the foundation for all downstream applications, including architectural glass, display glass, and optical components.

| Glass Type | Components | Characteristics | Applications |

|

Soda-Lime Glass |

SiO₂, Na₂O, CaO |

Light transmittance: 85–91%. Low cost, excellent workability, the most widely used glass type globally. |

Architectural windows, automotive glass, some display panels. |

|

Aluminosilicate Glass |

SiO₂, Al₂O₃ |

Light transmittance: 91–92%. High mechanical strength and thermal stability. Can be chemically strengthened for impact resistance. Divided by Al₂O₃ content into medium-alumina (8–12%) and high-alumina (12–13%) types. Typical representative: Corning Gorilla Glass® series. |

High-end display cover glass, electronic devices, in-vehicle displays. |

|

SiO₂, B₂O₃ |

Low thermal expansion and excellent chemical resistance. Cannot be tempered. Heat resistance: 450°C (long-term), 500°C (short-term). Typical representative: SCHOTT BOROFLOAT® 33. |

Laboratory ware, lighting, solar modules, precision optics. |

|

|

Fused Quartz (Silica) Glass |

SiO₂>99.9% |

Made from natural quartz fused at high temperature. Extremely low thermal expansion (1/10–1/20 of ordinary glass), high transparency, and superior chemical stability. Cannot be tempered. Heat resistance: 1100–1200°C (long-term), 1400°C (short-term). |

Optical windows, semiconductorequipment, precision optics, lasersystems. |

|

Appearance Type |

Characteristics |

Applications |

|

Clear Glass |

High iron content, greenish tint, visible light transmittance 89–91%. |

General construction, furniture, interior applications. |

|

Ultra-Clear (Low-Iron) Glass |

Low iron impurities, pure and bright color, light transmittance > 91%. |

Solar modules, display cabinets, electronic panels. |

|

Tinted Glass |

Colored by adding metal oxides (gray, bronze, black, etc.). |

Energy-saving and architectural curtain walls. |

|

Patterned (Rolled) Glass |

Textured or embossed surface patterns (square, ripple, prism, matte, diamond, etc.) |

Decorative and privacy glazing, skylights, daylight panels. |

Modern glass production primarily relies on four major manufacturing methods: the Float Process, Down-Draw Process, Overflow Process, and Rolling (Calendering) Process.

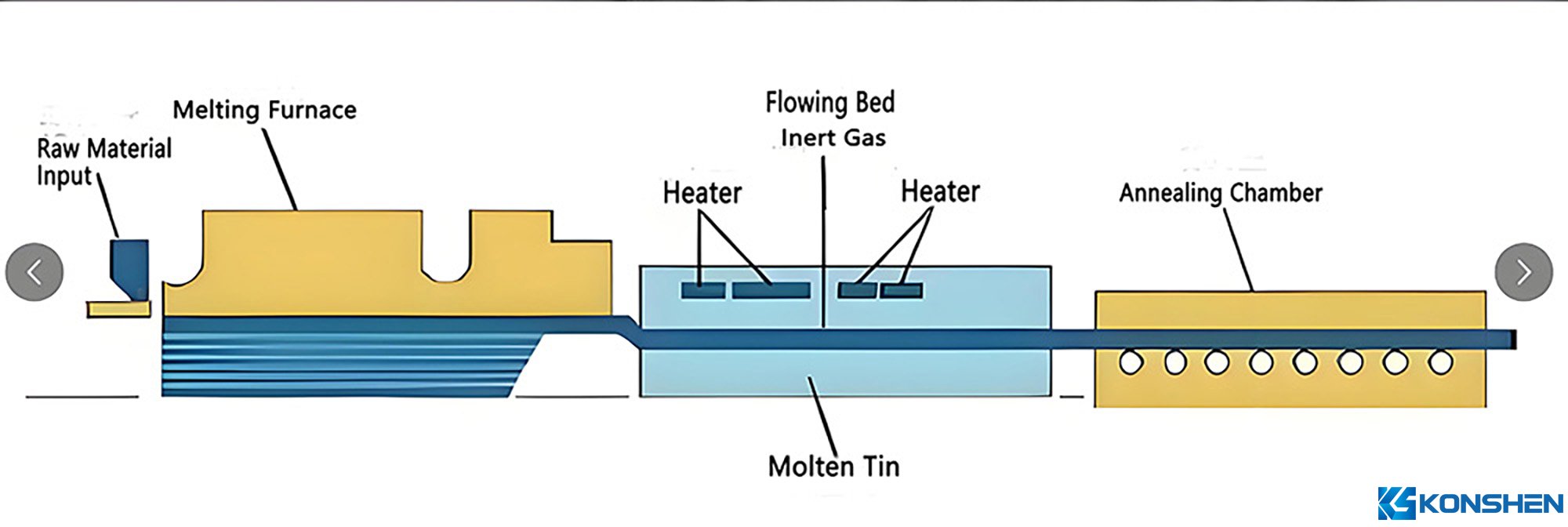

The Float Process is currently the most widely used method for producing flat glass substrates globally. It is commonly applied in architectural curtain walls, automotive windshields, home appliances, and photovoltaic glass.

This process was first invented and commercialized by Pilkington (UK) in 1959.

In the float process, molten glass flows from the melting furnace onto a bath of molten tin.Under gravity and surface tension, the glass spreads naturally across the tin surface, forming a flat ribbon with perfectly smooth upper and lower surfaces.

By precisely controlling temperature and draw speed, the glass thickness can be adjusted.The solidified glass ribbon is then drawn out of the tin bath onto a roller conveyor and sent to the annealing room to relieve internal stress.

Excellent surface flatness — no need for post-polishing.

Uniform thickness and stable production.

Difficult to achieve ultra-thin thickness (<1 mm) with consistent uniformity.

Not ideal for high-precision optical or specialty glass applications.

High capital investment in equipment; suitable only for large-scale continuous production.

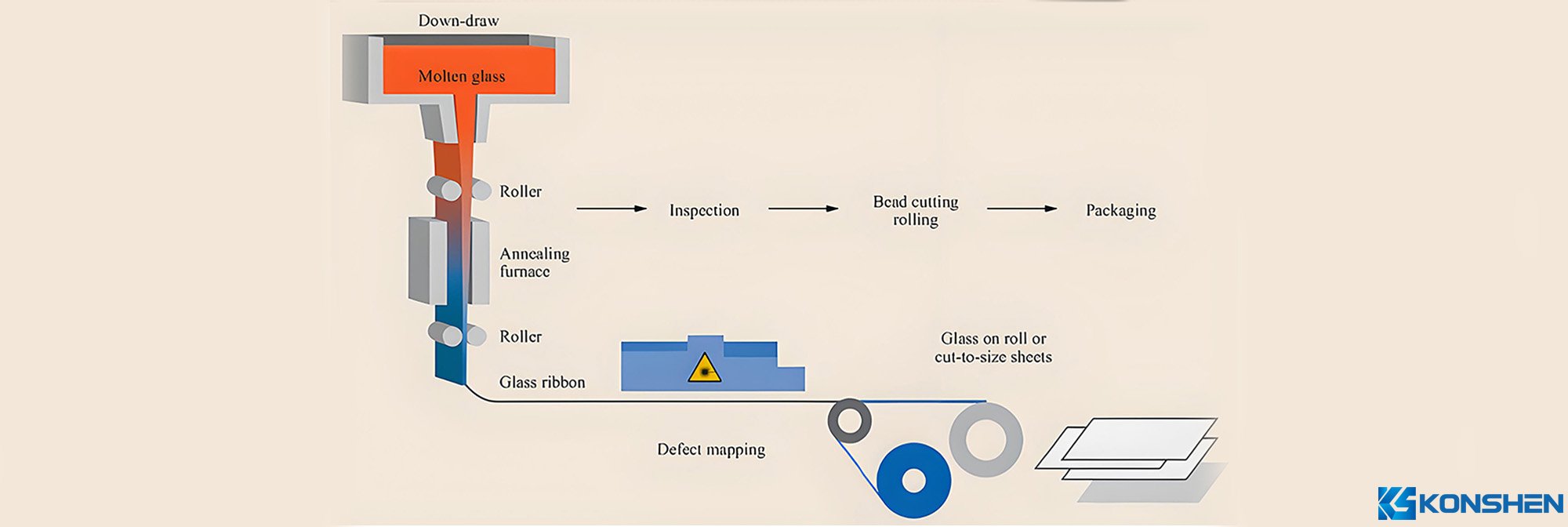

The Down-Draw Process is a continuous manufacturing method specifically developed for ultra-thin and high-precision glass. It is an industrial evolution of the vertical drawing method originally invented by Émile Fourcault (France, 1905).

This process is mainly used for display panels, touch screens, and precision optics.

Molten glass flows from the melting furnace into a forming trough, then is drawn downward along the outer walls of a precision mold by gravity and traction.

As the glass cools, it solidifies into a sheet, and its thickness is determined by the mold slot width and drawing speed.

During the forming process, both sides of the glass remain untouched by solid surfaces, ensuring an extremely smooth and defect-free finish.

Flawless surface finish — no roller contact, minimizing scratches or marks.

High thickness accuracy and uniformity; ideal for thin glass production.

No tin contamination, unlike the float process.

Stable and controllable production process.

Slower drawing speed and lower output than float glass.

Limited sheet width — not suitable for very large architectural glass.

High equipment precision and maintenance requirements.

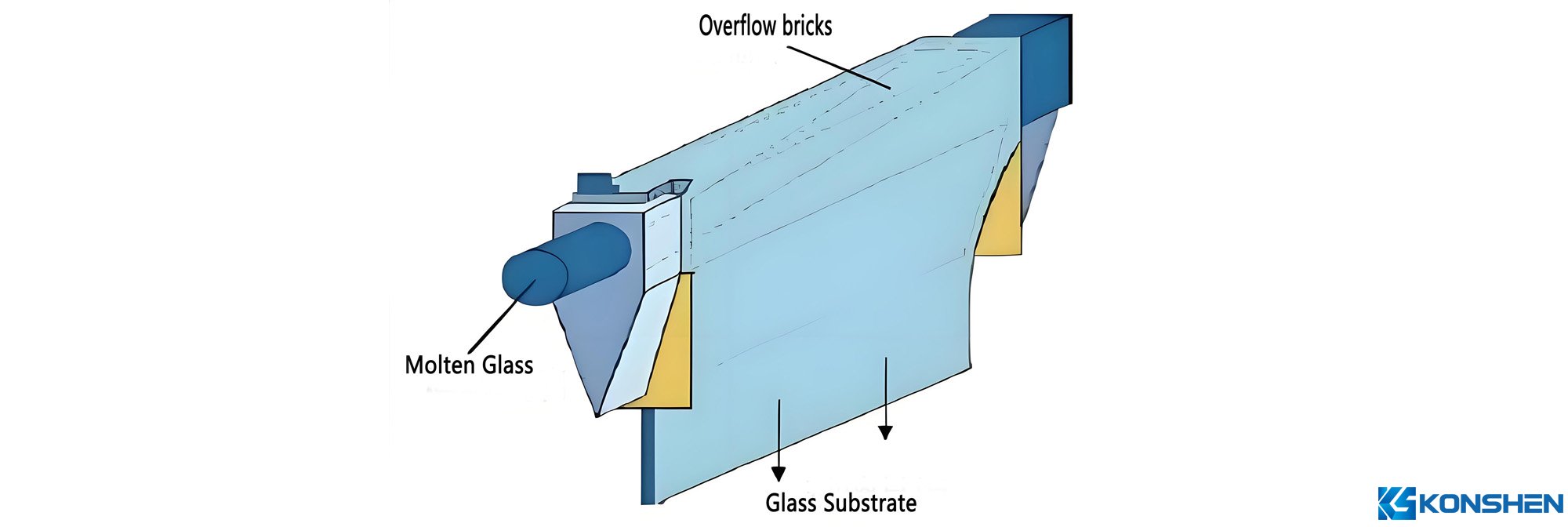

The Overflow Process, also known as the Fusion Draw Process, is an advanced evolution of the down-draw method. It was developed and industrialized by Corning Incorporated (USA) during the 1960s–1970s for manufacturing high-flatness ultra-thin display glass.

Molten glass flows from the melting furnace into a trough-shaped forming vessel with overflow lips on both sides.The glass overflows symmetrically down both sides and rejoins at the bottom center, naturally forming a continuous fusion ribbon.

Since the molten glass never contacts any solid surfaces during forming, both sides are exceptionally smooth.The glass ribbon then cools gradually and enters the annealing lehr to eliminate internal stress before being cut, inspected, and packaged.

Exceptionally smooth surfaces with high optical purity.

Excellent thickness accuracy and uniformity.

Precise width control through overflow trough design.

Low internal stress due to gradual cooling and annealing.

Ideal for high-end display and optical glass.

High process complexity and capital cost.

Mainly used for display and optical glass, not large-volume architectural glass.

Limited glass thickness range (0.4–6 mm typical).

Requires extremely pure raw materials — impurities can cause visible defects.

Process Relationship:

The Down-Draw Process is a modern refinement of the older vertical drawing method, while the Overflow Process is a further technological advancement of the down-draw technique.

All three aim for flat, uniform, and high-purity substrates, differing mainly in forming direction, contact condition, and achievable thickness precision.

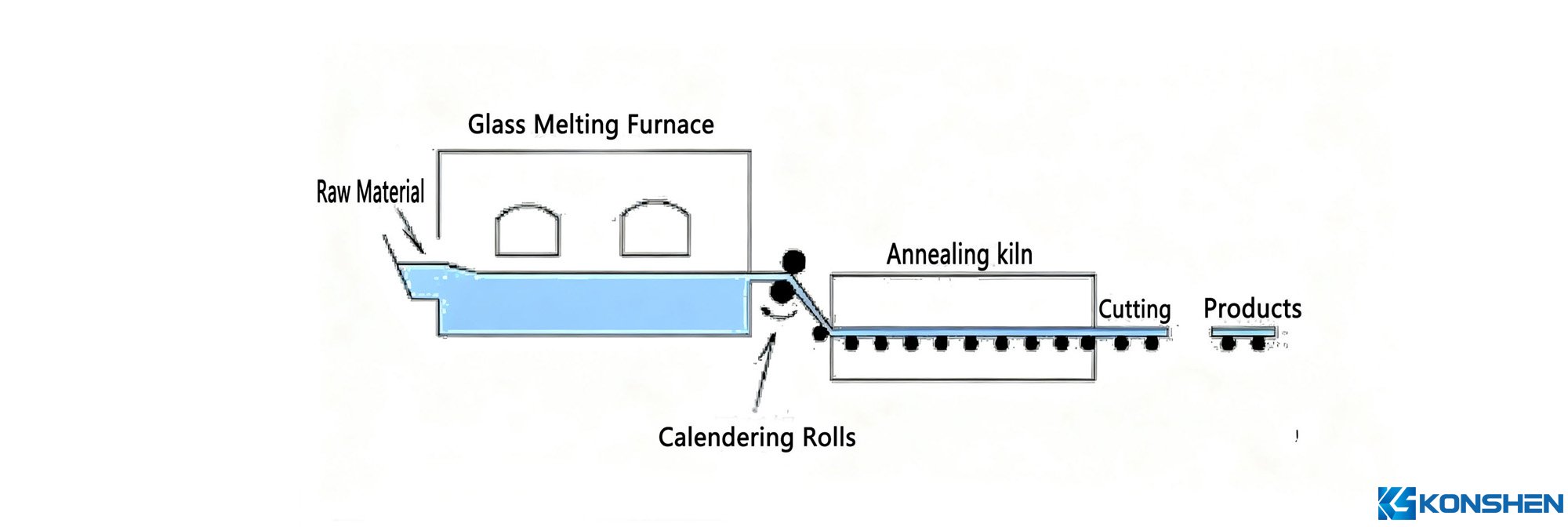

The Rolling Process (also called Calendering or Casting) forms flat glass through mechanical pressing or rolling of molten glass. It was first developed by French inventor Louis-Nicolas Robert.

Molten glass is poured into a roller machine or flat mold, where rollers or pressing plates compress it to the desired thickness.The glass is then annealed to remove internal stress, producing the finished sheet.The final thickness is controlled by adjusting the roller gap.

Simple and versatile process.

Suitable for thick or large-sized glass.

Lower equipment and operational costs.

Thickness uniformity inferior to float glass (±0.2–0.5 mm variation typical).

Slightly rough surface requiring post-polishing or coating.

Textured patterns may limit optical applications.

Lower production efficiency compared with float glass; best for specialty or decorative glass.

To ensure the stability and consistency of raw glass substrates, manufacturers evaluate them through two main dimensions: visual inspection and performance testing, supported by international and national standards.

Bubbles: trapped gas inclusions or air pockets within the glass body.

Inclusions: unmelted particles or impurities embedded during melting.

Scratches: surface abrasions formed during processing, handling, or drawing.

Mottles / Pitting: slight surface unevenness or fine pits on the glass.

Stones / Stone Spots: dense particle-like defects caused by raw material impurities or localized crystallization.

Bubbles: Diameter ≤ 0.5 mm acceptable; ≤ 5 pcs/m² (≥0.3 mm) uniformly distributed; no clustering.

Inclusions: Single inclusion ≤ 0.3 mm; ≤ 3 pcs/m², not concentrated in viewing area.

Scratches: Depth ≤ 1 μm acceptable; length ≤ 2 mm; no continuous or concentrated scratches.

Mottles / Pitting: Total mottled area ≤ 0.05 cm²/m²; ≤ 5 pcs/m²; avoid optical center area.

Stones / Stone Spots: Diameter ≤ 0.2 mm; ≤ 2 pcs/m²; none in center vision zone.

Note: The above parameters are common industry references. Actual standards may vary depending on product type (e.g., stricter for high-precision display glass).

Manual Optical Inspection: Conducted under standardized lighting or in a darkroom using both transmission and reflection observation to identify bubbles, inclusions, and scratches.

Optical Transmission Testing: Utilizes light transmittance detectors or CCD camera scanning systems to map and quantify bubble, scratch, and pit distribution.

Glass quality is also defined by its optical and physical characteristics, including:

Transmittance: measures light transmission capability.

Color Deviation (Chromaticity): measured using CIE color coordinates (x, y) or ΔE value.

Thickness Tolerance: indicates uniformity of sheet thickness across production batches.

Flatness: overall surface planarity; critical for optical and display applications.

Transmittance: ≥ 85% for general glass; ≥ 90% for high-precision display glass.±1% uniformity variation allowed.

Color Deviation (Chromaticity):≤ 1.5 (≤ 1.0 for display-grade glass).Minimal perceptible color difference.

Thickness Tolerance: ± 0.2 mm for standard glass; ± 0.05–0.1 mm for precision glass.Batch variation ≤ ±0.05 mm (for ultra-thin glass).

Flatness: ≤ 0.5 mm/m² for standard glass; ≤ 0.1–0.2 mm/m² for high-precision glass.Prevents optical distortion.

Transmittance: Measured using a spectrophotometer under standard illumination to determine transmission in visible and near-infrared ranges.

Color Deviation: Evaluated by colorimeter or spectrophotometer, comparing to reference whiteboards or standard samples via CIE color coordinates.

Thickness Measurement: Using vernier calipers, laser thickness gauges, or online thickness monitoring systems.

Flatness Measurement: Measured via laser interferometer, autocollimator, or precision flatness measurement table to detect bow, warp, or waviness.

|

Standard Code |

Scope |

Description |

|

EN 572-8 |

Appearance defects in flat glass |

European general standard for architectural glass. |

|

ASTM C1036 |

Classification and appearance of flat glass |

U.S. standard for building and furniture glass. |

|

GB/T 11614 |

Quality grades for flat glass |

Chinese national standard. |

|

GB/T 2680 |

Optical transmittance for glass |

Chinese optical inspection standard. |

The modern glass industry is highly concentrated, with a few global leaders mastering advanced manufacturing processes, strict quality management, and strong R&D capabilities.These manufacturers provide high-performance substrates widely used across architecture, automotive, electronics, optics, and solar industries.

Global Leading Glass Substrate Manufacturers:

|

Brand |

Country |

Founded |

Model |

Brand Positioning |

Main Applications |

|

AGC |

Japan |

1907 |

Float Glass |

A world-leading supplier of architectural, automotive, and electronic glass solutions. |

Curtain wall glass, automotive glass, display substrates, electronic glass. |

|

NSG |

Japan |

1918 |

Pilkington™ |

One of the global leaders in architectural and automotive glass. |

Energy-saving glass, automotive windshields, safety glass, display glass. |

|

Saint-Gobain |

France |

1665 |

COOL-LITE® |

A historical materials group offering sustainable and energy-efficient glass solutions. |

Architectural glass (facades, low-E windows), automotive glass, solar glass, low-carbon glass. |

|

Corning |

USA |

1851 |

Specialized in advanced glass and material innovation for electronics and optical fields. |

Smartphone and tablet cover glass, display substrates, optical fiber, semiconductor glass. |

|

|

SCHOTT |

Germany |

1884 |

BOROFLOAT® 33, D263® T eco |

A global supplier of high-end specialty glass and glass ceramics. |

Optical and instrument window glass, semiconductor substrates, solar aerospace glass. |

Procurement Tip:

When sourcing glass substrates, it is essential to evaluate not only price and lead time but also the supplier’s technical capability, quality consistency, and application suitability.

The following table lists standard substrate dimensions and thickness ranges commonly available in the global glass market.Actual specifications may vary depending on manufacturer, application, and processing capability.

|

Glass Type |

Common Substrate Sizes (mm) |

Typical Thickness Range (mm) |

|

Soda-Lime Glass |

1830*2440mm |

2/3/4/5/6/8/10/12/15mm |

|

Aluminosilicate Glass |

2440*3660mm |

0.33/0.4/0.55/0.7/0.8/1.1/1.5/2/3/4/5mm |

|

Borosilicate Glass |

1700*1300mm |

0.3/0.5/0.7/1.1/1.5/2/2.5/3/4/5/6/8/10mm |

|

Fused Quartz (Silica) Glass |

1200*1200mm |

0.3/0.5/1/1.1/1.5/2/3/4/5/6/8/10mm |

To ensure optimal performance, cost efficiency, and process compatibility, buyers should consider the following factors when sourcing raw glass materials:

(1) Select the Appropriate Glass Type

Choose the right substrate based on final application and performance requirements

Consider specific conditions such as heat resistance, impact strength, scratch resistance, UV protection, and chemical stability to ensure reliability in end-use environments.

(2) Select Standard Sizes and Compatible Thickness

Opt for standard sheet sizes to minimize cutting waste and reduce cost,match glass thickness with final product requirements and machining capacity to prevent warping or breakage and ensure processing equipment can handle the sheet’s dimensions and weight.

(3) Focus on Quality and Defect Control

Inspect raw glass for bubbles, scratches, pits, and surface waviness, which directly affect optical transmission and visual appearance.Pay attention to parameters such as flatness, refractive index, light transmittance, and thickness tolerance to guarantee batch consistency.For high-end or optical applications, perform sampling inspections or trial production runs before mass procurement.

(4) Ensure Safe Transportation and Storage

Glass substrates are fragile and susceptible to edge damage or cracking during handling.Use wooden crates or shockproof frames for packaging; avoid stacking too high or exposing to vibration.Store in dry, ventilated, and neutral environments, away from acids or alkalis.

For long-term storage, use protective films or paper interlayers to prevent surface contamination or scratches.

Energy Efficiency and Emission Reduction:

Modern glass factories are increasingly adopting high-efficiency combustion, waste heat recovery, low-energy furnaces, and eco-friendly raw materials to minimize energy consumption and carbon emissions.

Green Supply Chain:

More manufacturers are implementing sustainability across the entire lifecycle — from raw material sourcing and production to transportation and processing — ensuring compliance with international environmental standards such as ISO 14001 and REACH.

With the rapid evolution of smartphones, tablets, wearables, and flexible displays, ultra-thin glass (<0.5 mm) has become a key industry focus. This trend imposes higher demands on substrate uniformity, strength, and optical clarity.

Technical Challenges:

Producing ultra-thin glass while maintaining flatness, optical performance, and mechanical strength is difficult, particularly in cutting, tempering, and coating stages.

It requires high-purity raw glass, precision forming equipment, and stringent process control to ensure reliability.

Continuous innovation in raw glass manufacturing aims to achieve higher production efficiency, better quality uniformity, and lower energy and material consumption.

Intelligent Furnace Control:

Traditional float, overflow, and down-draw processes are being enhanced with AI-assisted furnace control, precision temperature regulation, and automated draw-speed management to improve flatness and thickness uniformity.

Energy Efficiency and Green Production:

Use of high-efficiency burners, waste heat recovery systems, low-melting-point raw materials, and electric melting technologies significantly reduces energy usage and carbon footprint.

Ultra-Thin Manufacturing:

Dedicated forming, cooling, and annealing processes are being developed for sub-0.5 mm glass, ensuring high strength, flatness, and excellent processability for downstream applications.

Digitalized Melting and Drawing Systems:

Real-time monitoring of furnace temperature, viscosity, and draw rate enables micron-level thickness control and consistent optical performance.

Automated Handling and Cutting Lines:

Fully automated conveyors and robotic interfaces connect forming and cutting stages, minimizing manual intervention and improving yield rates.

Industrial IoT (IIoT) Integration:

Sensors and big data analytics provide real-time diagnostics, predictive maintenance, and adaptive process adjustments — enhancing production stability and reducing downtime.

AI-Powered Defect Detection:

High-speed cameras and machine-learning algorithms identify bubbles, scratches, inclusions, and thickness variations in real time.

Optical Measurement Systems:

Interferometers, laser gauges, and refractometers ensure ultra-thin and optical-grade glass meets strict tolerance specifications.

Digital Traceability:

Through MES (Manufacturing Execution Systems) and integrated data recording, each batch can be tracked from melting to final delivery, improving quality assurance and reducing defect rates.

Glass substrates are vital industrial materials. From ancient glassblowing to modern float methods, advances have driven electronics and construction. Today, high transparency, low iron, thinness, and smart features guide material selection and innovation.For buyers and manufacturers, knowing glass processes and properties improves selection and opens new industry opportunities.

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us