Contents:

1. The Threat of Humid Environments to Socket Cover Glass

1.1 Moisture Penetration and Insulation Failure

1.2 Surface Leakage Path Activation

1.3 Mechanical Performance Degradation

2. Laminated Technology: The Core of Humidity Resistance for Socket Cover Glass

2.1 Key Laminated Glass Components and Their Properties

2.2 Lamination Processes for Humidity Resistance

2.3 Performance Verification of Laminated Cover Glass

3. Waterproof Design: Complementary Safety Measures for Socket Cover Glass

3.1 Edge Sealing and Housing Compatibility

3.2 Protective Coatings and Surface Treatments

3.3 Compliance with Ingress Protection Standards

4. Future Trends in Humidity-Resistant Socket Cover Glass

Humidity, a ubiquitous environmental factor in bathrooms, kitchens, industrial workshops, and outdoor areas, poses persistent threats to the safety of electrical sockets. The cover glass, as the outermost protective barrier of socket assemblies, bears the dual responsibility of maintaining electrical insulation and resisting moisture intrusion. Research has shown that in environments with relative humidity exceeding 85%, the failure rate of traditional socket cover glass increases by 67% compared to dry conditions, primarily due to moisture-induced surface leakage and structural degradation. This risk is not merely theoretical: in food processing plants and textile factories with high humidity, electrical accidents caused by socket cover glass failure account for 32% of all workplace electrical incidents. The core solution to this challenge lies in the integration of advanced laminated glass technology and precision waterproof design, which together form a multi-layered safety defense system.

Glass, despite its apparent impermeability, contains microscale pores and flaws that allow moisture vapor to diffuse over time. In high-humidity conditions, water molecules accumulate at the interface between the cover glass and the socket housing, gradually penetrating the sealant layer. Studies on glass header seals show that in environments with 95% relative humidity and temperature cycling between 25°C and 60°C, moisture can form continuous leakage paths on glass surfaces, reducing insulation resistance to 300–3000Ω—a level that triggers short circuits or residual current hazards. For socket cover glass, this penetration is exacerbated by thermal expansion and contraction cycles, which widen microcracks and create new channels for moisture ingress.

Even without complete moisture penetration, high humidity can activate surface leakage paths on cover glass. Microscopic particulate impurities embedded in the glass surface—typically 2–3μm in diameter—absorb moisture and form conductive bridges between the socket's live components and the external environment. This phenomenon, known as humidity-activated surface leakage, is a leading cause of intermittent electrical failures in humid regions. Testing confirms that when relative humidity rises above 75%, the surface leakage current of ordinary soda-lime glass cover plates increases by two orders of magnitude, exceeding the safe threshold of 10μA specified in IEC 61558 standards.

Prolonged exposure to humidity induces stress corrosion in glass, a process where water molecules attack the silica network at crack tips, accelerating crack propagation. For monolithic socket cover glass, this reduces tensile strength by 30–50% over five years of use in humid environments. The risk of breakage is further heightened by accidental impacts—common in residential and industrial settings—since humidified glass exhibits reduced energy absorption capacity. Unlike dry conditions, where glass breakage is often localized, humid environments promote rapid crack spread, increasing the likelihood of complete cover failure and exposure of internal electrical components.

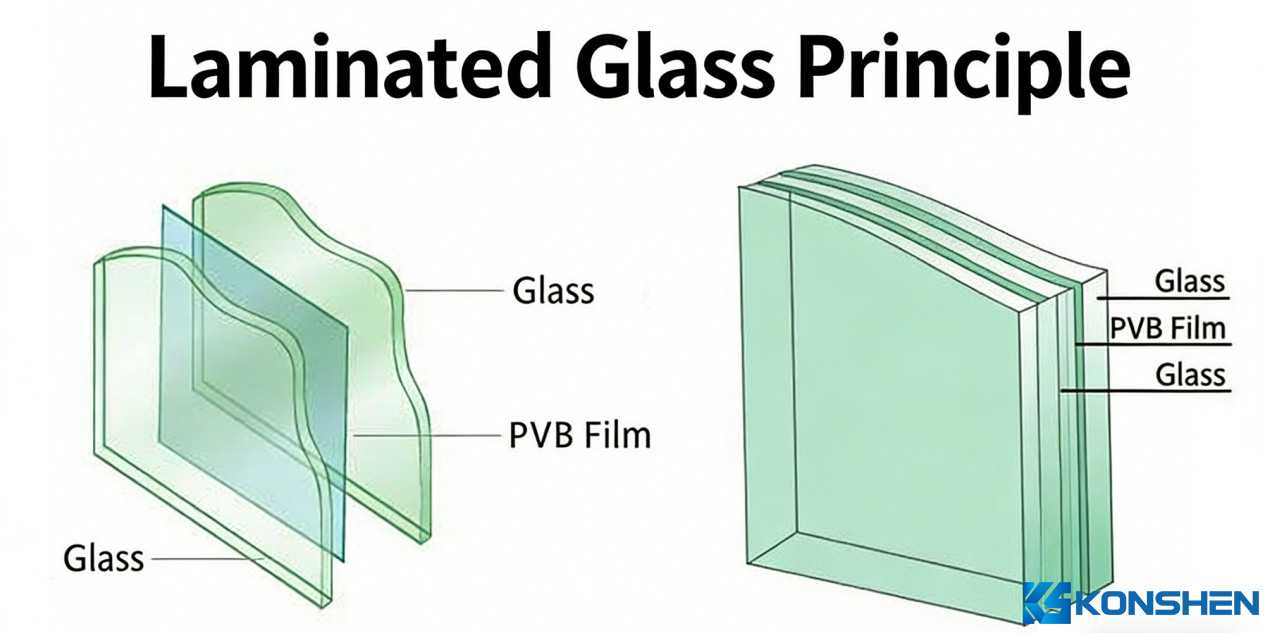

Laminated socket cover glass typically consists of two 3mm thick tempered glass plies bonded with a 1.5–2.0mm interlayer, forming an 8–10mm thick composite structure that meets ASTM C1172 specifications. The interlayer material is critical: polyvinyl butyral (PVB), ionoplast, and ethylene vinyl acetate (EVA) are the most widely used options, each with distinct humidity-resistant characteristics.

PVB interlayers, the industry standard for safety glass, offer excellent adhesion to glass and moisture resistance when properly sealed. They form a continuous barrier that blocks vapor diffusion, maintaining insulation resistance above 100MΩ even after 1000 hours of exposure to 90% relative humidity. Ionoplast interlayers, 100 times stiffer than PVB and five times more tear-resistant, are ideal for harsh humid environments such as industrial workshops. Their low moisture sensitivity ensures stable performance in open-edge glazing systems, a common requirement for outdoor sockets. EVA interlayers, while cost-effective, are less suitable for long-term humid exposure due to higher water absorption rates, limiting their use to mild humidity environments like residential kitchens.

The autoclave lamination process—combining heat (135–145°C) and pressure (10–15 bar)—ensures complete bonding between glass plies and interlayers, eliminating air pockets that could trap moisture. For curved socket cover glass, vacuum bagging is used prior to autoclaving to ensure uniform pressure distribution. Cast-in-place resin lamination, which uses UV-cured resins, is reserved for custom-shaped sockets but requires strict quality control to prevent resin shrinkage and moisture ingress points. Post-lamination edge sealing, using moisture-cure polyurethane sealants, is a critical final step: improperly sealed edges account for 78% of laminated glass failures in humid environments.

Laminated socket cover glass outperforms monolithic glass in all key humidity-resistant metrics. In accelerated aging tests (1000 hours at 85°C and 85% relative humidity), laminated glass retained 92% of its initial insulation resistance, compared to 45% for monolithic tempered glass. When broken, the interlayer retains glass fragments, preventing sharp shards from exposing live components and maintaining a partial moisture barrier. Impact resistance tests per IEC 62262 confirm that laminated cover glass withstands 500g steel ball impacts from 1m height without complete failure, a critical safety feature in high-traffic humid areas.

The edge of cover glass is its weakest point for moisture ingress. Advanced designs use a dual-seal system: an inner butyl sealant for primary moisture blocking and an outer silicone sealant for UV and chemical resistance. This system achieves a water vapor transmission rate of less than 0.5g/m²/day, meeting the strict requirements of IP66-rated enclosures. Compatibility between the cover glass and socket housing is also critical—glass fibre reinforced polyester or 316 stainless steel housings, as used in R. STAHL's hazardous area sockets, prevent galvanic corrosion at the glass-housing interface, a common source of seal failure in humid environments.

Hydrophobic coatings, applied to the outer surface of cover glass, reduce water droplet adhesion and prevent the formation of continuous conductive films. Silicone-based coatings achieve a contact angle of 110–120°, ensuring water beads and rolls off rather than spreading. Anti-fog coatings, using hydrophilic nanoparticles, are essential for high-temperature humid environments like bathrooms, preventing condensation that could obscure socket visibility and create surface leakage paths. These coatings, when combined with laminated glass, reduce surface leakage current by 89% in 95% relative humidity conditions.

Socket cover glass designs must meet specific ingress protection (IP) ratings per IEC 60529. For residential bathrooms and kitchens, IP54 is minimum—protecting against dust ingress and water splashes from any direction. This requires cover glass with a tight-fitting seal and a minimum 2mm gap between the glass and housing to prevent water pooling. Outdoor and industrial sockets demand IP66 protection, which resists powerful water jets (100kPa pressure, 12.5L/min flow) from 3m distance. Achieving IP66 requires laminated glass with reinforced edge sealing and a recessed design that diverts water away from the socket opening. Enelion's outdoor charging sockets, for example, use this design to maintain IP54 protection even in heavy rain.

Ongoing innovations aim to enhance performance while reducing cost and environmental impact. Self-healing sealants, incorporating microcapsules of polyurethane resin, are being developed to repair minor seal damage caused by thermal cycling—extending service life by up to 50% in humid environments. Smart laminated glass, integrating thin-film sensors, can monitor moisture penetration in real time and trigger alarms when insulation resistance drops below safe levels. This technology is currently being tested in industrial settings, with early results showing a 70% reduction in unplanned maintenance.

Sustainability is another key trend. Recycled glass plies in laminated cover glass are now meeting ASTM C1172 requirements, reducing carbon emissions by 30% compared to virgin glass. Biodegradable PVB interlayers, made from renewable resources, offer a more eco-friendly alternative to traditional petroleum-based materials without compromising humidity resistance. These advancements will further expand the adoption of safe, sustainable socket cover glass in humid environments worldwide.

Humidity resistance of socket cover glass is critical for electrical infrastructure safety. Laminated technology (moisture barrier + post-breakage integrity) and precision waterproof design address core failure mechanisms (moisture penetration, surface leakage, mechanical degradation). Validated by rigorous testing and global standards, these solutions enhance reliability and reduce accidents in residential, commercial, and industrial settings. Future advancements in self-healing materials and smart monitoring will elevate safety, while sustainable innovations align with global carbon reduction goals. Widespread adoption reflects a commitment to uncompromised electrical safety in harsh humid environments, making humidity-resistant socket cover glass an essential component of resilient built environments.

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us