Contents:

1. Structure and Working Principle of Vacuum Insulated Glass

1.1 Structural Composition

1.2 Core Working Principle

2. Performance Characterization of Vacuum Insulated Glass

2.1 Thermal Insulation Performance

2.2 Sound Insulation Performance

2.3 Mechanical Performance and Durability

3. Key Preparation Technologies of Vacuum Insulated Glass

3.1 Edge Sealing Technology

3.2 Vacuum Pumping Technology

3.3 Getter Technology

4. Application Status of Vacuum Insulated Glass

4.1 Architectural Field

4.2 Cold Chain Logistics Field

4.3 Photovoltaic Integration Field

Amid global climate change, countries worldwide have set carbon neutrality goals. The construction industry (30% of global energy consumption) is key for emission reduction. Glass, a vital building envelope component, has poor thermal insulation, causing massive energy loss. Traditional insulating glass (U-value 1.0–2.8 W/(m²·K)) fails to meet strict efficiency standards.

Vacuum Insulated Glass (VIG) is a new type of high-performance thermal insulation glass developed on the basis of vacuum thermal insulation principle. It realizes efficient thermal insulation by eliminating gas convection and reducing thermal conduction and radiation in the cavity. Since the 1990s, researchers from various countries have carried out in-depth research on VIG, and made significant breakthroughs in structural design, preparation technology and performance optimization. At present, commercial VIG products have been applied in architecture, cold chain logistics and other fields, and have shown significant energy-saving effects.

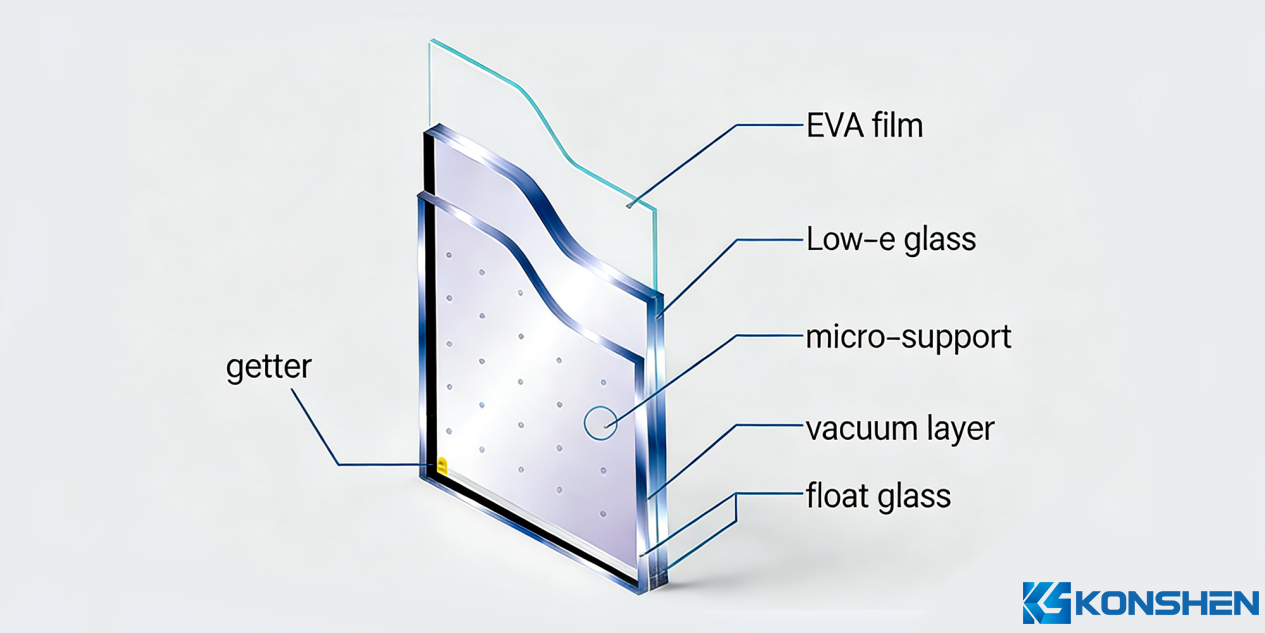

1.1 Structural Composition

The basic structure of VIG is composed of two or more pieces of tempered glass, edge sealing materials, spacers and getter materials. Among them, the glass substrate is usually low-iron tempered glass or ultra-white tempered glass, with a thickness of 3–6 mm, which ensures the mechanical strength and light transmittance of the product. The edge sealing material is the key to maintaining the vacuum degree of the cavity, and is usually made of low-melting-point glass powder, metal solder or organic-inorganic composite materials. The spacers are used to resist atmospheric pressure and prevent the glass sheets from collapsing, and are usually arranged in a regular grid with a spacing of 20–40 mm, a diameter of 0.3–0.5 mm and a height of 0.1–0.2 mm. The getter material is used to absorb the residual gas in the cavity and maintain the long-term stability of the vacuum degree, and common types include zirconium-aluminum alloy getters and nano-porous getters.

1.2 Core Working Principle

The thermal insulation mechanism of VIG is based on the three ways of heat transfer: thermal conduction, thermal convection and thermal radiation. In the vacuum cavity of VIG, the gas is almost completely removed, so the thermal convection between the glass sheets is fundamentally eliminated. At the same time, the inner surface of the glass sheet is coated with a low-emissivity (Low-E) film, which can reflect the far-infrared thermal radiation, thereby significantly reducing the radiant heat transfer. The remaining heat transfer mainly comes from the thermal conduction of the glass substrate and the spacers (thermal bridge effect).

The spacers are the main source of thermal conduction in VIG. To reduce the thermal bridge effect, researchers have optimized the material and structure of the spacers. For example, North Glass Group developed a micro-spring spacer, which reduces the thermal conductivity of the spacer by 35% compared with the traditional solid spacer, and at the same time improves the bending strength of VIG by 42%. In addition, the edge sealing material also has a certain impact on the thermal insulation performance. The use of low-thermal-conductivity edge sealing materials can further reduce the heat loss at the edge.

The thermal insulation performance of VIG is usually characterized by the U-value (heat transfer coefficient), which refers to the heat transfer per unit area per unit temperature difference per unit time. The lower the U-value, the better the thermal insulation performance. According to the published experimental data, the U-value of commercial VIG can reach 0.3–0.6 W/(m²·K), which is significantly lower than that of traditional double-layer insulating glass (1.0–2.8 W/(m²·K)) and triple-layer insulating glass (0.8–1.5 W/(m²·K)). For example, the Vacumax™ VIG produced by Vitro Architectural Glass has a U-value of 0.30 W/(m²·K) and a total thickness of only 8.3 mm. LandVac VIG has a U-value of 0.32 W/(m²·K), and its thermal insulation effect is equivalent to that of a 1.5 m thick brick wall.

The thermal insulation performance of VIG is affected by many factors, including the vacuum degree of the cavity, the thickness of the cavity, the type and structure of the spacers, and the performance of the Low-E film. Experiments show that when the vacuum degree of the cavity is lower than 1×10⁻² Pa, the U-value of VIG tends to be stable; when the thickness of the cavity is in the range of 0.1–0.2 mm, the thermal insulation performance is the best.

The sound insulation performance of VIG is characterized by the weighted sound reduction index (RW). Due to the elimination of gas in the cavity, VIG can effectively block the transmission of sound waves. The test data shows that the RW value of high-performance VIG exceeds 39 dB, and some products can reach 42 dB or more. Compared with traditional double-layer insulating glass (RW value 28–35 dB), VIG has a significant advantage in sound insulation, especially in blocking medium and high-frequency noise (such as human voice, car horn).

For low-frequency noise (such as vibration of heavy vehicles), the sound insulation effect of single-layer VIG is limited. Researchers usually improve the low-frequency sound insulation performance by designing composite structures (such as VIG combined with damping layers). The test shows that the composite VIG with damping layers can increase the RW value by 5–8 dB for low-frequency noise.

The mechanical performance of VIG is mainly reflected in bending strength and impact resistance. The bending strength of commercial VIG is usually 150–200 MPa, which meets the requirements of building glass. The impact resistance is related to the thickness of the glass substrate and the structure of the spacers. The use of tempered glass substrate can significantly improve the impact resistance of VIG.

Durability is an important index to measure the service life of VIG. The key to durability is the stability of the vacuum degree and the aging resistance of the edge sealing material. The accelerated aging test shows that the nano-porous getter material developed by Nanbo Group can effectively absorb the residual gas in the cavity, and the performance degradation rate of VIG is less than 0.8% per year under extreme climate conditions (temperature -40℃ to 80℃, humidity 85%). The service life of VIG can reach 50 years, which is equivalent to that of traditional building glass.

Edge sealing technology is the core technology of VIG preparation, which directly affects the vacuum degree and service life of VIG. Traditional edge sealing technologies include low-melting-point glass powder sealing, metal solder sealing and organic adhesive sealing. Low-melting-point glass powder sealing has the advantages of high sealing strength and good high-temperature stability, but the sealing temperature is high (350–450℃), which may cause thermal damage to the glass substrate. Metal solder sealing has high sealing efficiency, but the thermal conductivity is high, which increases the edge thermal bridge effect. Organic adhesive sealing has low sealing temperature, but poor aging resistance.

In recent years, micro-nano laser sealing technology has emerged as a new edge sealing technology. This technology uses laser to locally heat the edge sealing material, realizing low-temperature and high-precision sealing. The sealing temperature is reduced to 150–250℃, and the thickness of the edge sealing layer is reduced to 0.8 mm, which significantly reduces the edge thermal bridge effect. At the same time, the production yield of VIG is increased from 75% to 91%. North Glass Group has applied this technology to the mass production of VIG, realizing the continuous and stable production of VIG.

Vacuum pumping technology is used to remove the gas in the cavity of VIG to form a high vacuum environment. The traditional vacuum pumping method is to set a pumping port on the glass substrate, and use a vacuum pump to pump the gas, then seal the pumping port. This method has low pumping efficiency and is easy to cause air leakage at the pumping port.

The modern continuous vacuum pumping technology integrates the glass assembly and vacuum pumping into a production line. The glass assembly is put into a vacuum chamber, and the gas is pumped while the edge is sealed, which improves the pumping efficiency and vacuum degree. The vacuum degree of the cavity can reach below 1×10⁻¹¹ Pa·m³/s, which ensures the long-term stability of the vacuum degree. The fifth-generation continuous VIG production line developed by North Glass Group will be put into operation in 2026, with an annual capacity of 5 million square meters and a 32% reduction in unit energy consumption compared with the current production line.

Getter materials are used to absorb the residual gas in the cavity of VIG and the gas released by the edge sealing material and glass substrate during use, so as to maintain the vacuum degree of the cavity. Common getter materials include zirconium-aluminum alloy getters, titanium-zirconium alloy getters and nano-porous getters.

Nano-porous getter materials have become a research hotspot in recent years due to their large specific surface area and high adsorption capacity. The nano-porous getter material developed by Nanbo Group has a specific surface area of 800–1000 m²/g, which is 3–5 times that of traditional zirconium-aluminum alloy getters. It can absorb H₂, O₂, CO₂ and other gases, and the adsorption capacity is increased by 60% compared with traditional getters. The application of this material has significantly improved the durability of VIG.

The architectural field is the main application scenario of VIG, including new buildings and existing building energy-saving transformation. In new buildings, VIG is used in exterior windows, curtain walls and skylights, which can reduce building heating and cooling energy consumption by more than 60% compared with traditional glass. For example, in the energy-saving renovation project of an office building in Beijing, the use of VIG reduced the building's annual heating energy consumption by 62.3% and the annual cooling energy consumption by 58.7%.

In the energy-saving transformation of existing buildings, VIG has the advantage of thin thickness (total thickness 8–12 mm), which can be directly installed on the original glass without changing the original building structure. This reduces the transformation cost and difficulty. The energy-saving transformation project of old residential buildings in Shanghai using VIG has achieved a payback period of 7.5 years.

The cold chain logistics field has strict requirements on the thermal insulation performance and anti-condensation performance of glass materials. VIG has excellent thermal insulation performance and anti-condensation performance, which is suitable for refrigerated trucks, cold storage and display freezers. The cold chain-specific VIG produced by Fuyao Glass can maintain transparency without condensation even at -60℃, and the temperature difference between the two sides exceeds 70℃.

JD Logistics applied VIG to the cold storage of a logistics park in southern China. The test shows that the monthly energy consumption of the cold storage is reduced by 22.6% compared with the cold storage using traditional insulating glass, and the annual energy saving is about 120,000 kWh. This shows that VIG has significant energy-saving effects in the cold chain logistics field.

The integration of VIG and photovoltaic (PV) cells (PV-VIG) is an important development direction of building-integrated photovoltaics (BIPV). PV-VIG not only has thermal insulation performance, but also can generate electricity, realizing the dual functions of energy saving and energy generation. The PV-VIG developed by Suntech Power has a conversion efficiency of 24.3%, and the target conversion efficiency by 2026 is 25%.

PV-VIG has been applied in the curtain wall of a commercial building in Shenzhen. The curtain wall has a total area of 5,000 square meters, with an annual power generation capacity of 600,000 kWh, which can meet 15% of the building's annual electricity demand. This shows that PV-VIG has broad application prospects in the field of BIPV.

As a high-performance thermal insulation glass material, VIG has excellent thermal insulation, sound insulation and durability, and has broad application prospects in sustainable architecture, cold chain logistics and photovoltaic integration. The core working principle of VIG is to eliminate convective heat transfer through the vacuum cavity and reduce radiant heat transfer through the Low-E film, thereby achieving efficient thermal insulation. The key preparation technologies such as micro-nano laser edge sealing, continuous vacuum pumping and nano-porous getter have promoted the industrialization of VIG.

At present, VIG still faces challenges such as high production cost and difficult transportation and installation. In the future, with the optimization of production processes, the innovation of materials and the support of policies, the production cost of VIG will be further reduced, and the performance will be continuously improved. VIG will play an increasingly important role in promoting the energy-saving transformation of buildings, building low-carbon cities and realizing the carbon neutrality goal.

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us