| Thermal Expansion Coefficient | ~9 x 10⁻⁶ /°C |

| Thermal Conductivity | 0.9~1.0 W/m·K |

| U-Value: | 1.2-1.6 W/m²·K |

| R-Value: | 0.6 to 1.2 m²·K/W |

| Climatic Adaptability | withstand a broad temperature range (e.g., -40°C to +85°C) |

| Density: | ~2.5 g/cm³ |

| Refractive Index: | 1.5 |

| UV Cut-off : | Blocks up to 99% of UV Radiation |

| Light Transmittance: | 70%-90% visible light transmission |

| Color Rendering Index (CRI): | Typically above 90 |

| Maximum Operating Temperature: | Up to 200°C |

| Bending Strength: | 60-75Mpa for typical standard laminated glass(PVB or EVA interlayer) 500MPa for SentryGlas® interlayer |

| Compressive Strength | 100-150 MPa |

| Young's Modulus: | 60–75 GPa |

| Hardness (Moh's Scale) | 5-6 |

| Moisture Transmission Rate | PVB interlayer:0.1 to 1.0 g/m²·day EVA interlayer:0.05 to 0.5 g/m²·day SGP interlayer:< 0.01 g/m²·day |

| Impact Resistance: | High Impact Resistance,meeting ANSI Z97.1 or BS 6206 safety standards |

| Surface Resistivity | 10^12 to 10^16 ohms/sq |

| Volume Resistivity | 10^14 ohm·cm |

| Dielectric Strength | 0-50 kV/mm |

| Thermal Insulation Performance: | Good |

| Acoustic Insulation: | Sound Reduction Coefficient (SNR): ~40 dB (depending on interlayer material and thickness) |

| Lifetime Performance: | Service Life: Laminated glass is designed to perform reliably for 10-20 years, depending on environmental conditions, and is resistant to fading, discoloration, and physical degradation. |

Customer Visit

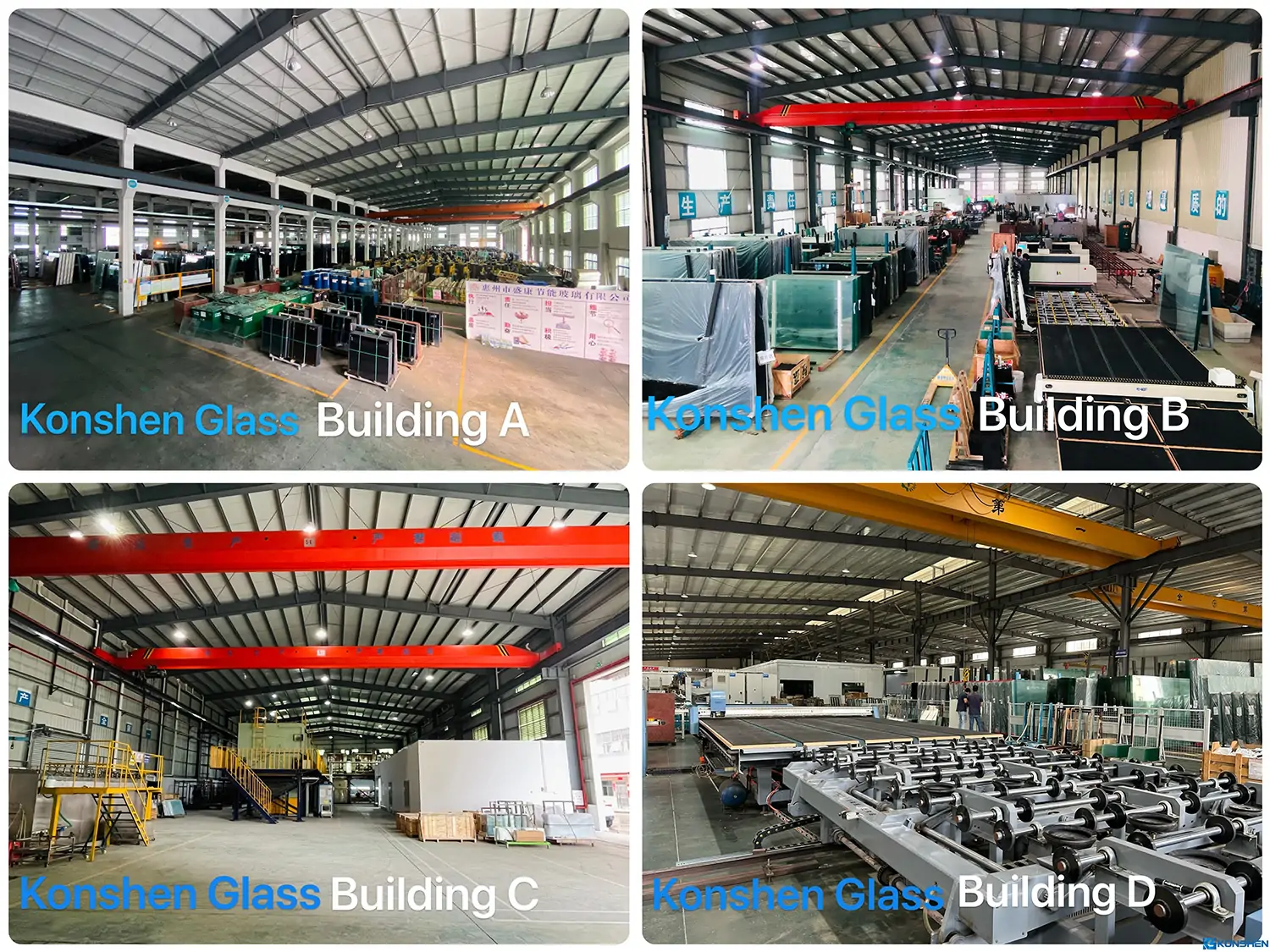

Company Profile

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us