Key Features:

High Light Transmission: Crafted from high-grade low-iron glass with high light transmittance, ensuring optimal visual performance for display and optical applications.

Safety Edge Processing: Precision edge processing improves both safety during handling and aesthetic integration into device enclosures or visible installations.

Superior Durability: Thick and stable glass body resists impact, thermal fluctuations, and mechanical stress, making it ideal for demanding industrial environments.

Clean Appearance: Smooth, dust-resistant edges ensure a polished, professional look for visible installations.

Customized Option:

Available Thickness: Ranging from 0.33 mm to 10 mm, depending on the insulation requirements and specific applications.

Size & Shape: Supports special-shaped cutting to meet diverse needs. Customizes as per drawing.

Cutting Option: CNC Cutting/Water jet Cutting/Diamond Blade Cutting

Edge Options: Polished Edge/Safety Edge/Beveled Edge/Smooth Edge/2.5D Edge/Pencil Edge/Straight Edge

Tempering Options: Physical Tempered/Checmical Strengthened

Coating Options: Anti-Reflective (AR) Coating/Anti-Fingerprint (AF) Coating/Scratch-Resistant Coating or Anti-Glare (AG)Coating.

Printing Options: UV Printing/Silk screen printing/Laser engraving printing

Adhesive Options: AB Tape/ Double-side Tape/3M Adhesive

Materials: Ultra Clear Soda Lime Glass

Shape: Round

Thickness: 2mm

Edge Work: Safety Edge

Tempered Method: Physical Tempered

Transmission Rate: 90%

Density: 2.5 g/cm³

Mohs Scale: ≥7H

Strengthness: IK07

Operating Temperature Range: Suitable for -30°C to 250°C.

Thickness Tolerances:± 0.2mm

Dimensional Tolerances:±0.5mm for large size; ±0.1mm for small size

Surface Quality: No visible scratches, bubbles, or inclusions under inspection light

Weather Resistance: Strong resistance to high temperatures and humidity, reducing aging effects

Precision Optics: Used in protective covers for optical lenses, microscopes, and inspection equipment, ensuring high transmittance and image clarity.

Electronic Displays: Suitable for screens, smart terminals, and touch panels, offering reliable surface protection.

Lighting Systems: Applied in LED lamps, spotlights, and display cabinet lights as protective covers, ensuring clear light output and sleek appearance.

Interior Decoration & Art Design: Common in modern home interiors, architectural finishes, and glass artwork, combining aesthetics and durability.

Industrial Protection: Ideal for high-demand environments like observation windows and machine viewports, with excellent heat and impact resistance.

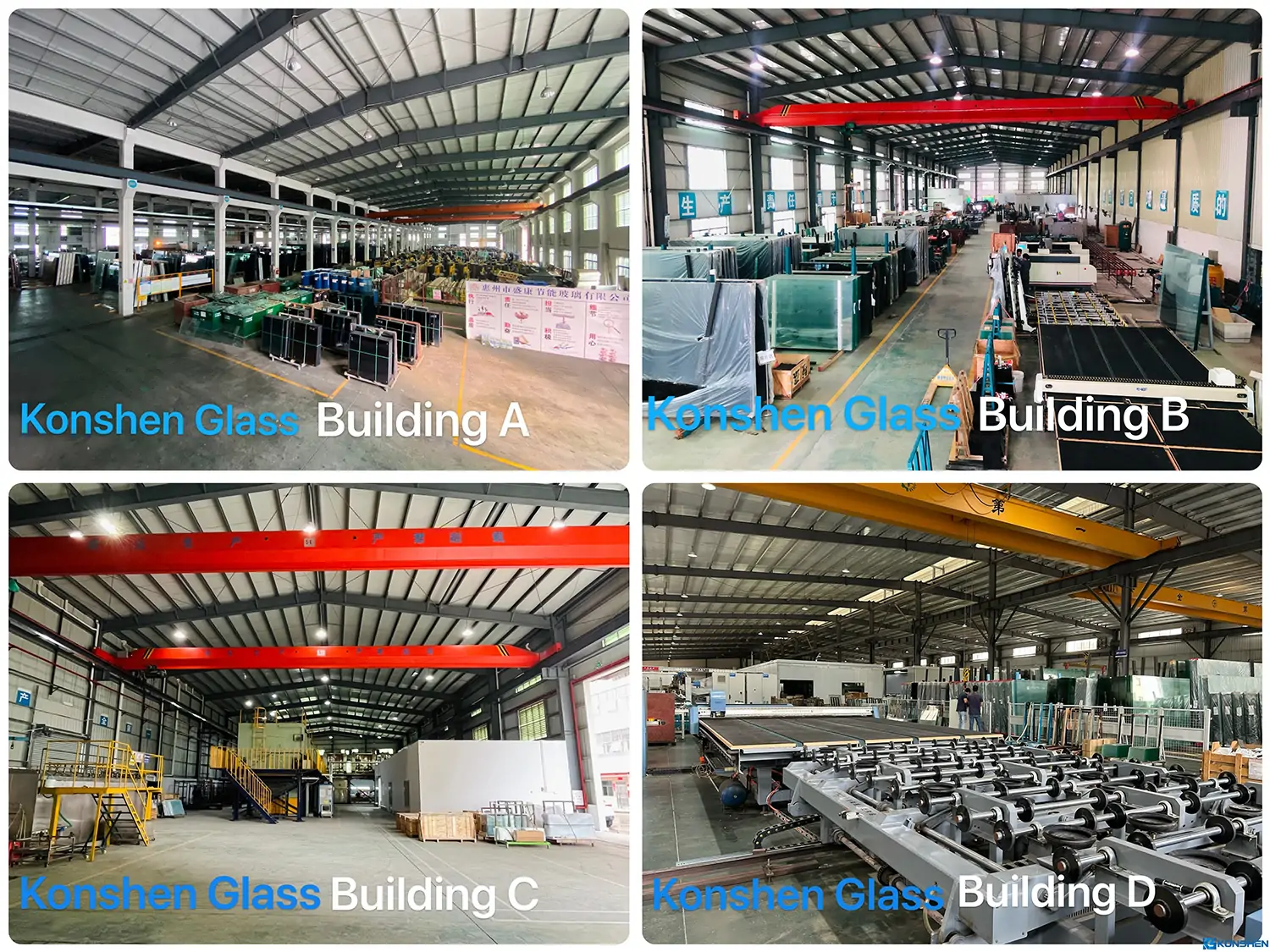

Customer Visit

Company Profile

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us