Key Features:

Ultra-Thin Thickness: Manufactured from 0.8mm ultra-thin low-iron glass, this panel delivers a lightweight structure while maintaining mechanical strength, ideal for compact and portable electronic systems where space and weight are critical.

2.5D Edge Treatment: The 2.5D edge chamfering process provides a smooth, curved edge that enhances tactile comfort and elevates the overall look and feel, making it suitable for premium devices and user-facing panels.

High Opacity Black Silk Printing: The high-opacity black silk printing offers excellent light blocking, ensuring inner components are hidden for a clean visual design. It's also heat- and abrasion-resistant, making it suitable for visible and functional interfaces.

Custom Precision CNC Shaping: Fully customizable to complex shapes via CNC machining, including curves, notches, and holes, this glass can match any device housing or design drawing with high precision.

Safety Edge Polishing: All edges are safety polished and deburred to prevent injury and ensure secure handling during assembly, enhancing reliability in both industrial and consumer applications.

Customized Option:

Materials Options: Soda Lime Glass,Mid-Aluminum Glass,High-Aluminum Glass

Available Thickness: 0.33 mm to 10 mm, customizable for different application needs.

Size & Shape: KS Glass offers various custom shapes and sizes tailored to your specifications.

Cutting Options: Laser Cutting,Water jet Cutting,Diamond Blade Cutting,CNC

Edge Options:Polished Edge,Safety Edge,Beveled Edge,Smooth Edge,2.5D Edge,Pencil Edge,Straight Edge

Tempering Options:Physical Tempered/Checmical Strengthened

Coating Options: Anti-Reflective (AR) Coating,Anti-Fingerprint (AF) Coating,Scratch-Resistant Coating(AS),Anti-Glare Coating(AG)

Printing Options: UV Printing,Silk screen printing,Laser engraving printing

Adhesive Options: AB Tape, Double-side Tape,3M Adhesive

Materials: Soda Lime Glass

Shape: Custom

Thickness: 0.8mmT

Edge Work: 2.5D edge by CNC engraving carving machine

Tempered Method: Chemical Strengthened

Coating: Anti-fingerprint(AF) coating

Printing Method: Silk screen printing #RAL9004 BK

Transmission Rate: ≥ 90%

Density: 2.5 g/cm³

Hardness: at least 6H

Strengthness: IK07

Operating Temperature Range: Suitable for -30°C to 250°C.

Thickness Tolerances:± 0.2mm

Dimensional Tolerances:±0.5mm for large size; ±0.1mm for small size

Weather Resistance: Strong resistance to high temperatures and humidity, reducing aging effects

UV Resistance: High UV-blocking capability

Impact Resistance: 2-5 times stronger than standard glass. Specific impact resistance can vary based on thickness and treatment.

Smart Home Control Panels: Widely applied in smart home devices such as gateways, video doorbells, environmental monitors, and touch switches. The elegant appearance and precise fitting significantly enhance product quality and user interaction.

Medical Instruments & Portable Terminals: Its scratch resistance, chemical durability, and ease of cleaning make it ideal for use in medical tablets, handheld diagnostic tools, and portable health monitoring devices.

Touch Interface Front Covers: Designed for capacitive and infrared touch systems, the printed mask layer defines transparent and sensing zones precisely, enhancing touch accuracy and system performance.

Consumer and Industrial Display Covers: Used in e-labels, smart meters, wearables, and more, this cover glass is fully customizable in shape and aesthetics, providing seamless integration with both consumer and industrial devices.

Equipment Display Windows: Acts as a protective window for instruments, control panels, and specialized terminals, offering high transmittance and scratch resistance for optimal performance in demanding environments.

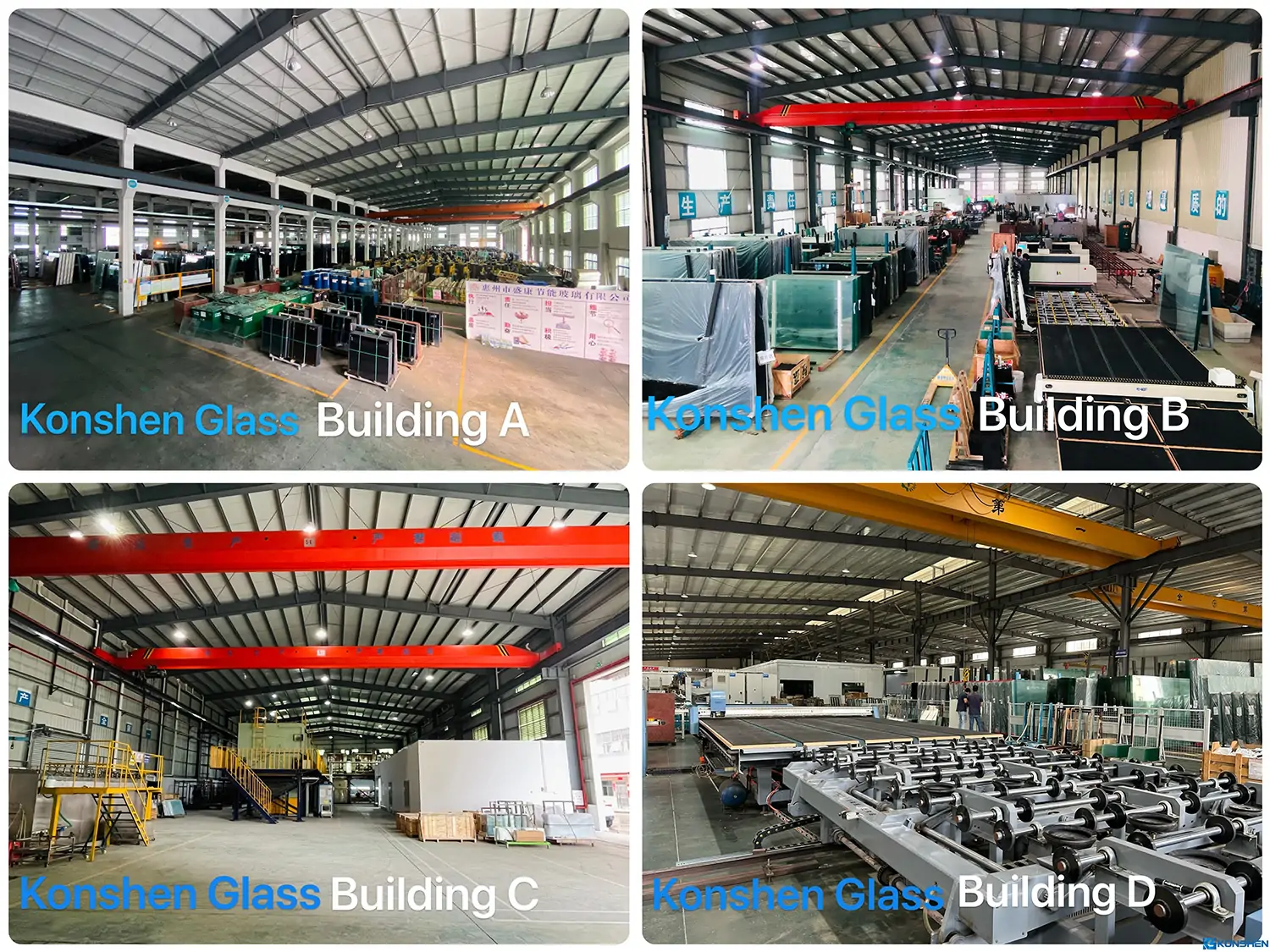

Customer Visit

Company Profile

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us