| Thermal Properties | Softening Point: 700°C |

| Maximum Operating Temperature: Up to 290°C for continuous use | |

| Thermal Expansion Coefficient: 9.5 x 10⁻⁶ /°C | |

| Thermal Shock Resistance: Withstands temperature variations up to 250°C without breaking | |

| Heat Transfer Coefficient: 5.8 W/m²K (depending on glass thickness) | |

| Temperature Gradient Tolerance: Up to 200°C across the surface | |

| Mechanical Properties | Density: 2.5 g/cm³ |

| Poisson's Ratio: 0.23 – 0.25 | |

| Young's Modulus: 70-75 GPa | |

| Glass strength grade:IK07 or higher | |

| Impact Resistance: 5 times stronger than standard glass | |

| Hardness (Moh’s Scale):6 to 7 | |

| Compressive Strength: 800 – 1000 MPa | |

| Tensile Strength: 40 – 120 MPa | |

| Bending Strength: ≥ 120 MPa (approximately 4 to 5 times stronger than annealed glass) | |

| Modulus of Rupture: 150 – 200 MPa | |

| Maximun Working Size: | Outer Dimension:2440*1600mm |

| Thickness:2-19mm | |

| Tolerances: | Thickness Tolerances:± 0.2mm |

| Dimensions Tolerances:±0.5mm for large size; ±0.1mm for small size | |

| Flatness:≤ 0.5mm per meter |

Customer Visit

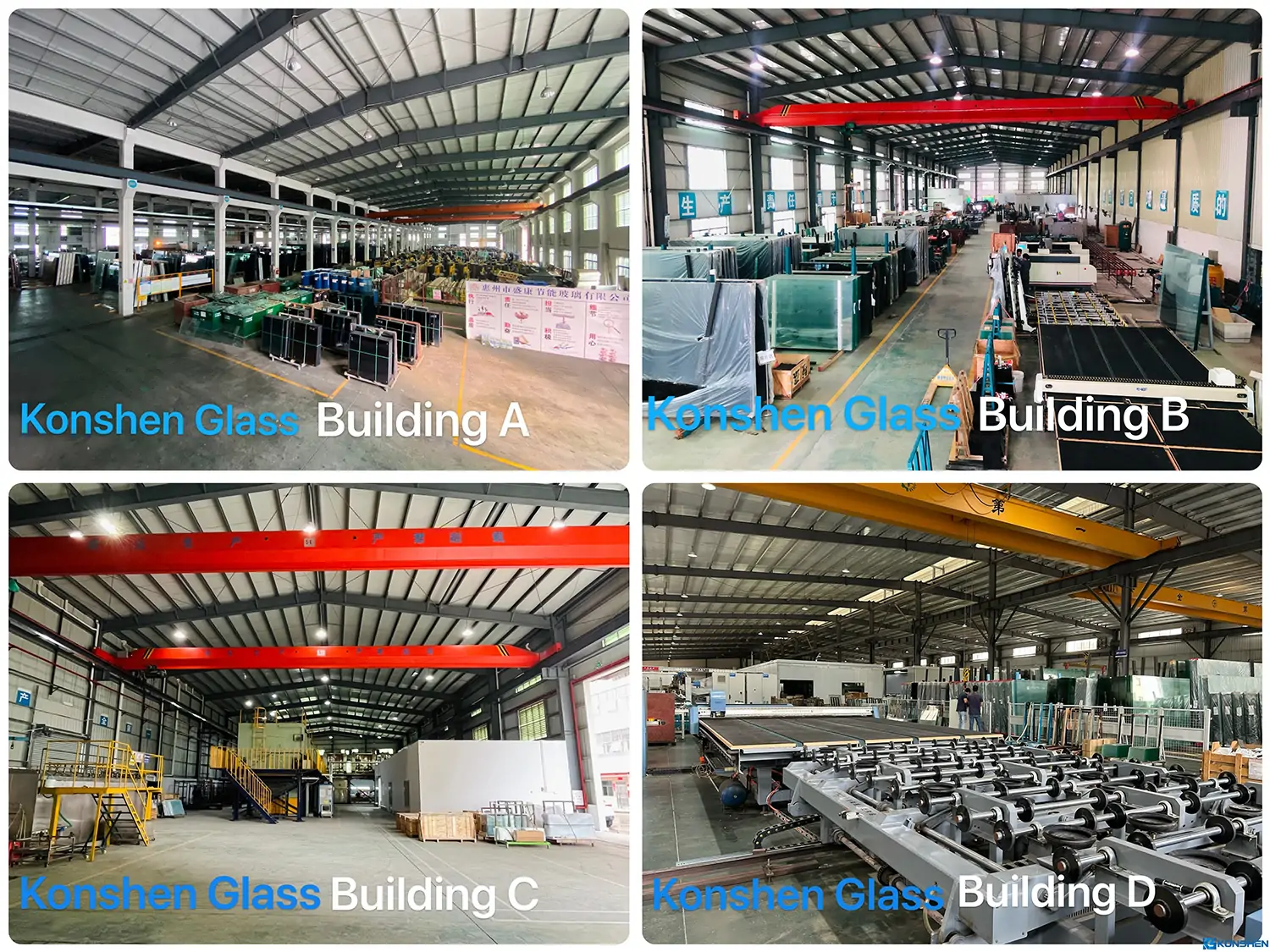

Company Profile

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us