Content:

1. The Principles of Anti-Fingerprint Technology in Cover Glass

1.1 Surface Energy and Contact Angle

1.2 Microstructure: Engineering Surface Roughness

1.3 Coating Adhesion: From Surface Application to Chemical Bonding

1.4 Comparative Analysis of Technologies

2. Three Generations of Anti-Fingerprint Technology

2.1 First Generation: Silicone Oil Coating

2.2 Second Generation: AF Coating

2.3 Third Generation: Nano Composite Coating

3. Practical Benefits in Real-World Use

3.1 Effortless Cleaning

3.2 Long-Term Durability

3.3 Enhanced Aesthetics and Functionality

3.4 Improved Hygiene

4. Advanced Applications of Cover Glass

4.1 Children’s Room: Anti-Fingerprint + Blue-Light Filtering Glass

4.2 Kitchen/Bathroom: Humidity-Resistant Anti-Fingerprint Glass

4.3 Budget Smart Switches: Economy Nano Composite Glass

4.4 High-End Smart Homes: Custom-Textured Anti-Fingerprint Glass

4.5 Retrofit Solutions: Anti-Fingerprint Glass Overlays

Smart home switches have evolved beyond simple push-button devices to incorporate functionalities such as dimming, curtain control, and appliance integration. However, a persistent issue remains: glass panels, once cleaned, quickly accumulate fingerprints with minimal contact, resulting in unsightly smudges. Over time, oil buildup can even impair switch responsiveness. In households with children, frequent touching introduces bacteria, complicating cleaning efforts. User expectations for smart switches are straightforward: reliability, aesthetic appeal, and ease of maintenance. The upgrade in anti-fingerprint technology for the protective cover glass—a core component of switch panels—directly addresses these demands. From initial simple coatings to advanced composite technologies, the efficacy of anti-fingerprint glass has significantly improved.

Anti-fingerprint technology may seem complex, but it fundamentally alters the surface properties of glass—either by modifying its structure to prevent oils from adhering or by facilitating easy removal.

Fingerprints primarily consist of oils, which readily adhere to standard glass due to its high surface energy. Anti-fingerprint coatings reduce this surface energy, minimizing oil adhesion.

A practical indicator is the behavior of oil droplets on the surface: spreading indicates high adhesion, while beading into discrete droplets signifies low adhesion. High-quality anti-fingerprint glass promotes beading, allowing effortless removal of oils.

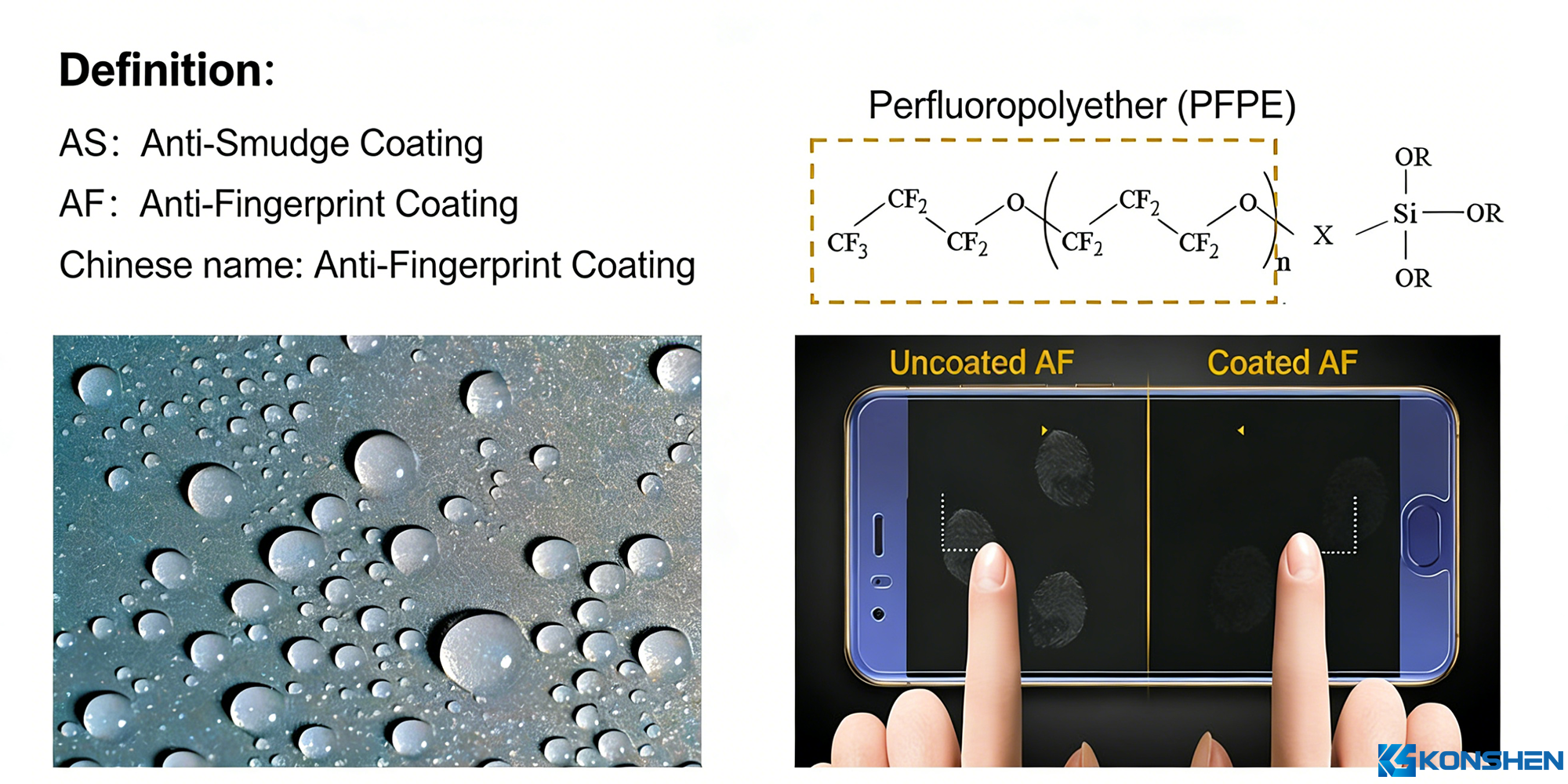

Fluorine-based anti-fingerprint (AF) coatings leverage fluorine’s low surface energy to repel oils. Nano composite coatings further enhance clean ability by enabling water to spread rapidly, carrying away contaminants.

Beyond reducing surface energy, some technologies modify the glass’s microstructure. For instance, anti-glare glass features microscopic protrusions (significantly finer than a human hair) created via chemical processes. These structures reduce the contact area with fingerprints by up to 90%, preventing adhesion and simplifying cleaning.

Nano composite coatings incorporate micro-pores that host nano silver particles, providing durable antibacterial protection without compromising wear resistance.

Coating durability hinges on adhesion strength:

- First-generation silicone oil coatings adhere superficially and wear off easily.

- Second-generation AF and third-generation nano-composite coatings form chemical bonds with the glass, ensuring superior abrasion resistance and longevity.

|

Technology type |

Surface energy (mN/m) |

Oil droplet contact angle |

Hardness (H) |

Number of wear-resistant cycles |

Antibacterial effect |

Product lifespan |

Core principle |

|

Ordinary glass |

45 |

60°-70° |

6-7 |

- |

No |

- |

The surface is prone to sticking to oil |

|

Silicone oil coating |

30-35 |

80°-90° |

2-3 |

≤500 times |

No |

1-3 months |

The surface is sprayed with an oil-resistant film |

|

Ordinary AF coating |

20-25 |

100°-110° |

4-5 |

2500-5000 times |

Weak |

1-2 years |

Contains fluorine, oil-resistant and durable |

|

Nanocomposite coating |

≤20 |

110°-120° |

10 |

≥100,000 times |

Up to standard |

10-15 years |

Net-like film, oil-resistant and antibacterial |

2. Three Generations of Anti-Fingerprint Technology

2. Three Generations of Anti-Fingerprint TechnologyAnti-fingerprint technology for smart switch glass has progressed through three key stages, each enhancing practicality:

Early smart switches used tempered glass with a silicone oil coating, which formed a thin, oil-repellent layer. However, these coatings had low hardness, wearing off after a few hundred wipes and lasting only 1–2 months. They also caused hazing, reducing indicator visibility.

AF coatings, now common in mid-range switches, utilize fluorine-based compounds to create a durable, low-energy surface. Similar to lotus-leaf effects, these coatings cause oils to bead up, enabling easy wiping. They withstand over 2,000 abrasion cycles and achieve oil contact angles exceeding 110°.

The latest nano composite coatings integrate anti-fingerprint,antibacterial,and scratch resistant properties. For example, silica-based films embedded with nano silver offer active protection. Key advantages include:

- Exceptional hardness (10H), resisting scratches from keys or nails;

- Exceptional hardness (10H), resisting scratches from keys or nails;

- Ultra-high abrasion resistance (>100,000 cycles), equivalent to 15 years of use;

- Antibacterial efficacy against common pathogens like E. coli and S. aureus;

- Enhanced cleanability with rapid water spreading for effortless stain removal.

Anti-fingerprint technologies deliver tangible improvements:

Nano-composite coatings enable cleaning with a damp cloth in seconds, eliminating the need for repetitive scrubbing or alcohol-based cleaners.

While standard AF coatings degrade after 1–2 years, nano-composite coatings last over a decade, aligning with typical renovation cycles and reducing replacement costs.

Modern coatings maintain high transparency (>92% light transmittance) for clear indicator visibility. Anti-glare options ensure a smudge-free appearance from any angle.

Antibacterial coatings achieve >99% reduction in common bacteria, ideal for high-touch areas like kitchens and bathrooms.

Specialized switches for children combine anti-fingerprint coatings with blue-light filtering particles, reducing indicator glare by 80% while ensuring easy cleaning and antibacterial protection.

Coatings with anti-fog additives prevent condensation and oil buildup, maintaining performance in humid conditions without degradation.

Scaled-down nano composite coatings now feature in affordable switches, offering robust anti-fingerprint and scratch resistance (50,000+ cycles) with 8–10-year lifespans.

Premium panels include matte or metallic finishes that minimize visual smudges while complementing interior designs (e.g., Scandinavian matte white or industrial gray).

Premium panels include matte or metallic finishes that minimize visual smudges while complementing interior designs (e.g., Scandinavian matte white or industrial gray).

Ultra-thin (0.3 mm) AF-coated adhesives allow easy upgrades for existing switches, enhancing durability and cleanliness without electrical modifications.

The evolution of cover glass for smart switches from silicone oils to nano composites reflects a persistent drive toward durability, ease of maintenance, and adaptability. By manipulating surface properties and structures, these technologies repel contaminants and meet diverse household needs. For consumers, this translates to reduced cleaning effort, extended product lifespans, and scenario-specific options. Future advancements may include self-healing surfaces and seamless integration with wall materials, further embodying the smart home ethos of convenience and comfort. In the coming years, anti-fingerprint technology will likely eliminate one of the last nuisances of smart switches, delivering unparalleled reliability and peace of mind.

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us