Content:

Introduction

1. What Is Glass UV Printing Technology?

1.1 Definition and Technical Characteristics of Glass UV Printing

1.2 Main Classification of Glass UV Printing

2. Advantages of UV Printing in Cover Glass Manufacturing

2.1 Application Advantages

2.2 Comparison Between UV Printing and Screen Printing

3. Glass UV Printing Process

3.1 Process Flow

3.2 Equipment

3.3 Ink System

4. Quality Inspection Of Glass UV Printing

4.1 Quality Inspection Items

4.2 Common Inspection Standards and Methods

4.3 Common Defects and Engineering Solutions

5. Applicability and Selection Recommendation

6. Limitations and Considerations of UV Printing in Cover Glass Processing

In industries such as consumer electronics, industrial control, smart home appliances, and medical devices, continuous upgrades in product form and functionality have driven cover glass to evolve from a simple protective component into an integrated element combining structural protection, functional implementation, visual presentation, and brand identification. Whether used for touch display interfaces, functional indicator areas, or brand logos and decorative patterns, cover glass now plays an increasingly critical role in overall product design.

At the same time, market demand structures are undergoing significant changes. On one hand, end products are being updated at an accelerated pace, with frequent design iterations. On the other hand, the number of projects involving small-batch trial production, customized development, and multi-version parallel validation continues to grow. Traditional surface decoration processes, primarily screen printing, still maintain irreplaceable advantages in stability and cost efficiency during mass production. However, their limitations in sampling efficiency, design flexibility, and development cycle have gradually become apparent.

Against this backdrop, UV printing technology has been introduced into cover glass manufacturing as a complementary process. UV printing is not intended to replace conventional screen printing, but rather to address practical challenges encountered during the prototyping stage, small-batch production, and applications requiring high flexibility.

This article provides a systematic analysis of the application of UV printing technology in cover glass processing, covering its definition, process principles, advantages, quality control, and selection considerations, helping readers develop a clearer and more rational technical understanding.

Glass UV printing is a non-contact printing process based on digital inkjet technology. Its core principle involves directly jetting UV-curable inks onto the glass surface through printheads, followed by instantaneous curing using ultraviolet light, allowing the printed patterns to rapidly form and adhere to the glass surface.

From a technical perspective, glass UV printing typically exhibits the following key characteristics:

First, it is a digital printing process. All pattern data is directly driven by digital files without the need for physical screens or printing plates, significantly reducing the cost and time associated with design modifications.

Second, UV printing is a non-contact process. There is no mechanical contact between the printhead and the glass surface, minimizing physical stress on the substrate. This is particularly advantageous for thin glass or structurally complex cover glass products.

Third, UV printing utilizes UV-curable inks. These inks rapidly undergo crosslinking reactions under ultraviolet irradiation, enabling fast image formation while reducing risks such as ink flow or pattern distortion.

Finally, the process enables direct image formation on the glass surface without intermediate transfer media, simplifying the workflow and reducing the likelihood of pattern misalignment or positioning errors.

In cover glass manufacturing, UV printing can generally be classified from two perspectives: equipment configuration and ink effect.

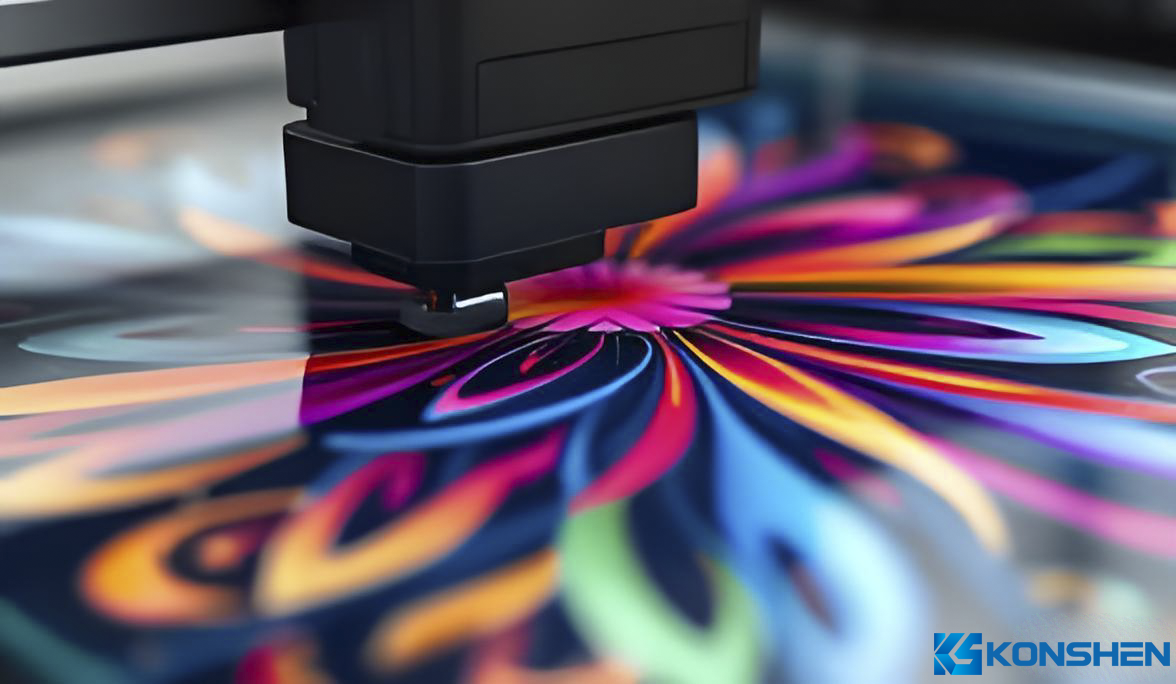

From an equipment perspective, the most widely used solution is flatbed UV printing. In this configuration, glass substrates are fixed on a flat working table while printheads move along the X and Y axes to complete pattern deposition. This method is suitable for the majority of flat cover glass products and offers high positioning accuracy and resolution.

From the perspective of ink and visual effects, UV printing can be divided into standard color UV printing, white ink or white base UV printing, and localized raised or textured UV printing. Among these, white ink layers are commonly used to enhance opacity and color contrast, while raised ink effects are mainly applied for decorative purposes and are less common in functional cover glass applications.

Impact of Plate-Free Printing on Project Development

In traditional screen printing processes, plate making is an unavoidable preliminary step. Each pattern or color combination requires a dedicated screen, increasing upfront development costs and extending the time from design finalization to sample delivery.

In engineering projects, the plate-free nature of UV printing effectively reduces decision-making costs during the design freeze stage. Before patterns and color schemes are finalized, engineering teams can complete multiple rounds of sample validation with lower time and cost investment, minimizing the risk of rework caused by late-stage design changes. This flexibility is particularly valuable in new projects where iterative modifications are unavoidable.

Significance of Pattern Freedom in Design Validation

From an engineering perspective, UV printing excels in rendering color gradients, fine details, and complex graphics, making it highly suitable for design validation phases. In contrast, screen printing has inherent limitations when handling complex gradients and fine lines, often requiring multiple printing steps or specialized screen designs. UV printing allows more accurate reproduction of design intent, enabling design teams to obtain visual feedback that closely resembles final product appearance during the sample stage, thereby reducing the likelihood of repeated revisions.

Coordination Between Localized Printing and Structural Design

Cover glass products typically include both functional and decorative areas. UV printing enables localized pattern deposition without affecting the surface properties of surrounding regions, providing greater design freedom. Engineers can flexibly adjust pattern layouts according to functional requirements without being constrained by full-area printing logic.

From an engineering and mass production perspective, UV printing is not a complete replacement for screen printing. Each process has its own focus in practical applications:

|

Comparison Aspect |

UV Printing |

Silkscreen Screen Printing |

|

Plate Requirement |

No plates required |

Plates required |

|

Suitable Production Volume |

Prototyping / small batches |

Medium to large batches |

|

Color Performance |

High flexibility, suitable for gradients |

Stable, high repeatability |

|

Pattern Complexity |

High |

Limited by screens |

|

Unit Cost |

Advantageous for small batches |

Advantageous for large batches |

|

Adhesion & Durability |

Process-dependent |

|

|

Typical Application Stage |

Prototyping / design validation |

Mass production |

In cover glass manufacturing, the stability of UV printing does not depend solely on the printing equipment itself but is jointly determined by factors such as glass substrate condition, surface treatment methods, ink systems, and curing parameters. From an overall process perspective, a typical UV printing workflow includes glass cleaning, surface pretreatment, UV printing, UV curing, and integration with subsequent processes.

Glass Surface Pretreatment:

Surface pretreatment quality directly determines ink adhesion stability. Glass inherently has low surface energy, and the presence of oil contamination, dust, or machining residues can easily result in poor ink adhesion. Common pretreatment methods include alcohol cleaning, ionized air dust removal, and plasma treatment to remove contaminants, followed by elimination of surface moisture and residual oils.

Application of Adhesion Promoter Coatings:

To enhance ink adhesion, a dedicated primer or coating is often applied to the cleaned and dried glass surface via spraying or lint-free wiping. After moisture and oil removal, coating application should typically be completed within 10 minutes to prevent reabsorption of moisture.

Printing Parameter Setup:

Printing software is configured with white ink and color ink printing functions, as well as resolution and feathering parameters. These settings directly affect print quality and efficiency.

Printing Process:

The prepared glass is placed securely on the UV printer platform with precise positioning. During printing, equipment status must be monitored to prevent issues such as nozzle clogging. UV-curable inks solidify instantly upon exposure to UV light, forming strong adhesion. Due to the transparency of glass, UV light can penetrate the substrate and facilitate rapid curing. Curing parameters must be carefully optimized, as insufficient curing can lead to poor scratch resistance, while excessive curing may increase internal stress and reduce durability.

Post-Processing:

After printing, additional surface treatments such as clear coating may be applied to enhance gloss and mechanical robustness.

Cover glass UV printing typically utilizes industrial-grade flatbed UV printers, comprising inkjet systems, UV curing systems, vacuum adsorption platforms, motion control systems, ink supply systems, and control software with RIP functionality.

Cover glass UV printing typically utilizes industrial-grade flatbed UV printers, comprising inkjet systems, UV curing systems, vacuum adsorption platforms, motion control systems, ink supply systems, and control software with RIP functionality.

Industrial piezoelectric printheads ensure high-precision ink deposition, directly influencing pattern clarity, edge quality, and consistency. UV curing systems use LED UV lamps that provide low heat output, low energy consumption, and long service life, making them suitable for temperature-sensitive glass substrates.

Vacuum platforms stabilize glass positioning during printing, while servo-driven motion control systems ensure accurate printhead movement, especially critical for multilayer printing and large-format applications. Ink supply systems maintain stable pressure and flow to minimize clogging risks. RIP and control software handle image processing, color management, white ink layering, and special effects, forming the backbone of high-quality UV printing.

UV-curable inks are the most commonly used inks in glass UV printing. They consist mainly of pigments, photoinitiators, oligomers (resins), and reactive diluents. Under UV irradiation, photoinitiators trigger polymerization, enabling rapid film formation. This curing mechanism does not rely on substrate absorbency, making it ideal for smooth, non-porous materials such as glass.

Role of White Ink:

Role of White Ink:White UV ink is essential for transparent or ultra-clear glass applications. Used as a base or blocking layer, it significantly enhances color saturation and contrast. Due to its high pigment density, white ink requires stable ink circulation and agitation systems.

Color Inks and Color Performance:

Color UV inks typically follow a CMYK configuration, offering high color accuracy and weather resistance. Through RIP color management and controlled layering, gradients, fine lines, and high-resolution patterns can be achieved.

Clear Varnish (Clear Ink):

Clear inks provide surface protection and aesthetic enhancement, enabling glossy, matte, or tactile effects. They can also improve scratch and chemical resistance to a certain extent.

In practical projects, UV inks are generally required to comply with environmental regulations such as RoHS.

In cover glass applications, UV printing is not merely a decorative process. Its quality stability directly affects assembly performance, end-use reliability, and long-term durability. Therefore, quality inspection must be conducted through comprehensive evaluation based on printing characteristics, glass substrate properties, and application environments.

|

Inspection Item |

Description |

|

Adhesion |

The most critical parameter. UV inks rely on physical adhesion and chemical bonding rather than fusion, making them highly sensitive to surface conditions. |

|

Pattern Integrity & Edge Definition |

Essential for visible and interactive areas, affecting overall appearance and brand perception.

|

|

Color Consistency |

In cover glass projects, color control in UV printing typically needs to be defined as consistency within a controllable color difference range, rather than absolute color value replication.

|

|

Surface Defects |

|

Cross-Cut Test:

A standard method for evaluating ink adhesion by observing peeling after grid cutting. Results are typically judged based on customer specifications rather than a single universal standard.

Visual and Magnification Inspection:

Conducted under standardized lighting conditions, supplemented by magnification to evaluate micro-defects, pattern details, and surface uniformity.

Customized Inspection Requirements:

Certain industrial, medical, or high-end projects may require additional tests such as abrasion resistance, basic chemical resistance, or post-assembly appearance evaluations.

Based on KS's extensive project experience, UV printing in cover glass manufacturing is primarily applied in the following scenarios:

During early development stages, when patterns, colors, and layouts are not finalized and multiple rounds of physical validation are required, UV printing is often preferred as a verification process due to its fast turnaround.

For small-batch customized projects with high pattern variability, UV printing offers advantages in cost and flexibility.

For multi-version parallel development projects targeting different markets or customer requirements, UV printing efficiently supports rapid version switching.

For ultra-large-volume production, outdoor applications requiring high wear and weather resistance, or products requiring stringent long-term reliability validation, traditional screen printing or other mature processes remain more suitable.

Adhesion and Long-Term Reliability:

From a material bonding perspective, UV ink layers rely on surface adhesion. Their long-term durability under friction and chemical exposure differs structurally from sintered screen-printing inks and is generally lower.

Limitations of Base Color Selection:

UV printing typically relies on white ink as the base layer, which may impose limitations on base color selection.

Compatibility with Tempering and Chemical Strengthening:

UV printing is generally unsuitable before thermal tempering or chemical strengthening, imposing stricter requirements on process sequencing and yield control.

Scratch Resistance and Aging Performance:

Under high-frequency touch or prolonged use, UV ink surfaces may exhibit scratches, gloss variation, or localized wear, necessitating protective coatings or structural compensation.

Overall, UV printing technology in cover glass manufacturing is not intended to fully replace traditional screen printing. Instead, it serves as a complementary solution better suited for prototyping, small-batch production, and high-flexibility applications. With appropriate process selection and control, UV printing can provide greater design freedom and faster development cycles, effectively supporting product innovation.

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us