Glass, as an indispensable fundamental material in modern manufacturing, plays a crucial role in various industries thanks to its exceptional transparency, aesthetics, chemical stability, and mechanical strength. Its applications extend across consumer electronics, optical instruments, automotive, architecture, medical devices, and high-end industrial fields. Cutting is the first and most critical step in transforming glass from raw sheets into finished products. The precision of this process directly affects subsequent stages such as edge grinding, coating, tempering, and assembly. Poor cutting quality not only leads to product rejection but can also compromise safety and durability.

With the advancement of industrial automation and intelligent manufacturing, glass cutting technologies continue to evolve. From traditional manual cutting to diamond wheel cutting, laser cutting, and waterjet cutting—and now toward emerging methods such as ultrasonic and optically assisted cutting—each technique has its own advantages, limitations, and ideal application scenarios.

This article provides a comprehensive analysis of glass cutting methods, applicable materials, quality standards, cost considerations, and environmental factors, serving as a practical reference for manufacturers, buyers, and process engineers.

In modern glass deep-processing workflows, raw glass sheets are first cut into specific sizes and shapes using suitable cutting techniques, followed by CNC edge grinding. The smoothed edges are then subjected to physical or chemical tempering to improve strength and safety. Depending on the end-use requirements, additional processes such as coating and screen printing may be applied before final cleaning, inspection, and packaging.

As the first step in glass deep processing, cutting defines not only the basic geometry and dimensions of the glass but also its initial edge quality and stress distribution. Uneven edges or micro-cracks generated during cutting can become stress concentration points in later tempering or coating processes, increasing the risk of breakage. Cutting inaccuracies may also complicate edge grinding and cause assembly deviations in the final product—an especially critical issue in electronics, optics, and automotive glass, where even minor dimensional errors can affect performance and user experience.

Therefore, glass cutting is not merely a basic manufacturing step—it is a key process for ensuring quality, reducing material waste, and enhancing overall product reliability.

The significance of glass cutting can be understood from three key perspectives:

Dimensional Accuracy

In the production of high-end displays, touch panels, and optical components, dimensional precision is critical. Even the slightest deviation can result in poor lamination, light leakage, or frame misalignment. For instance, excessive dimensional errors in automotive instrument glass or optical windows can directly affect installation accuracy and optical axis alignment, leading to performance degradation.

Edge Quality

The smoothness and defect control of cut edges determine the glass's crack resistance during subsequent tempering or lamination. If chipping, burrs, or micro-cracks are present, these flaws become stress concentration points that increase the likelihood of breakage during thermal or mechanical processing.

Stress Control

Residual stress induced during cutting, if not properly relieved, may lead to micro-crack propagation during tempering or service, reducing overall strength and durability. This is especially critical for ultra-thin or high-hardness glass. Improper stress control can cause hidden fractures or breakage even under light external forces.

|

Typical Application |

Key Quality |

Precision Requirement |

Cutting |

Recommended Cutting Method |

|

OLED Displays |

Bonding accuracy, light transmittance, visual consistency, anti-shattering performance |

±0.05~±0.1 mm |

Ultra-high precision cutting with no chipping or micro-cracks; often combined with CNC secondary trimming or laser cutting for full-lamination designs. |

Laser Cutting |

|

Home Appliance Panels |

Heat resistance, safety, surface flatness, appearance quality |

±0.1~±0.2 mm |

Edges must be smooth and safe(chipping < 0.1 mm); supports rounded or chamfered corners for aesthetics and user safety. |

Diamond Wheel Cutting |

|

Industrial Control Panels |

Structural strength, impact resistance, long-term reliability |

±0.15~±0.3 mm |

Slight edge roughness acceptable if it doesn’t affect installation; consistency and hole-position accuracy are prioritized. |

Diamond Wheel Cutting |

|

Optical & Laboratory Instruments |

Optical precision, light transmittance, no stress fringes, surface cleanliness |

±0.02~±0.05 mm |

Extremely high dimensional accuracy with stress-free cutting and crack-free edges. |

Laser Cutting |

The above data is based on typical industrial standards and manufacturing experience. Specifications can be customized according to customer requirements.

There are various methods for glass cutting, each suitable for different glass types, thicknesses, and application scenarios. Common cutting methods include manual cutting, diamond wheel cutting, waterjet cutting, laser cutting, and linear cutting. Regardless of the method used, it is essential to reserve an additional 1–2 mm in size to allow for material loss during subsequent CNC edge grinding.

Manual cutting utilizes the brittle nature of glass and the unique blade design of a glass cutter. The cutter scores a fine scratch line on the glass surface along a marked path. Internal stress within the glass then propagates along the score line, and by applying a controlled breaking force, the glass fractures neatly along the incision to achieve clean separation.

Manual glass cutting mainly relies on the glass cutter and auxiliary tools. The cutter head is typically made of hard alloy or oil-lubricated tungsten carbide, featuring a beveled edge that creates fine score lines on the surface to guide the fracture. Oil-lubricated cutters reduce friction and enhance smoothness, ideal for thin or high-transparency glass, while solid alloy cutters are more suitable for medium or thick glass but require careful force control to avoid micro-cracks. The cutting angle and applied pressure are crucial for achieving clean, even edges.

|

Classification |

Type of Glass Cutter |

|

By Head Shape |

Straight-handle, Angled, T-shaped, Compass type, Plate type, Oil-fed type |

|

By Wheel Material |

Diamond wheel, Alloy wheel |

|

By Function |

Diamond wheel, Alloy wheel |

| Tip Model | Applicable Thickness |

| 2mm | 2-4mm glass |

| 2.5mm | 4-6mm glass |

| 3mm | 6-8mm glass |

| 4mm | 8-10mm glass |

| 5mm | 10-12mm glass |

During manual cutting, straightedges or guide rails are essential to ensure straight and stable scoring lines. Small glass pieces can be aligned with steel rulers, while large or precision glass panels benefit from sliding rail systems that maintain cutting accuracy within ±0.1 mm. The flatness and anti-slip performance of the cutting table also affect the final quality. Operators should wear gloves and safety goggles, use marking pens or water-soluble templates for layout, and employ plastic or wooden breakers to apply even force and minimize edge chipping.

Low equipment cost and simple operation, ideal for small batches or on-site adjustments.

Efficient for cutting thin glass sheets (≤ 3 mm).

Highly flexible for custom or irregular sizes.

Cutting accuracy depends heavily on operator skill, making it prone to errors.

Edges are susceptible to micro-cracks or chipping, affecting subsequent tempering quality.

Not suitable for mass production.

Diamond wheel cutting operates by engraving the glass surface with diamond particles embedded on the wheel, while cooling fluid controls the cutting temperature to minimize thermal stress. The glass is then separated through mechanical breaking or controlled vibration, resulting in a clean and precise cut.

A diamond wheel cutting machine is designed for high-precision and thick glass cutting. Its core component is a rotating wheel embedded with ultra-hard diamond particles. The wheel scores the glass surface at high speed, and the diamond grit size and wheel diameter are selected based on glass type and thickness. For ultra-clear thin glass, fine-grain, high-speed wheels are preferred for smooth cuts, while coarse-grain wheels are used for thick or high-hardness glass to enhance efficiency. Regular inspection and replacement of worn wheels are essential to maintain cutting precision and edge integrity.

The cooling system plays a vital role during cutting. High-pressure spray or recirculating coolant not only reduces the temperature of the wheel and glass surface to prevent thermal stress but also provides lubrication to extend tool life. The coolant is typically maintained at 20–25 °C with a steady flow rate to prevent micro-cracks caused by thermal expansion.

The support platform and clamping system are equally crucial, ensuring the glass remains stable and flat during cutting to avoid vibrations or sagging that could compromise line accuracy.

Suitable for most glass types with minimal restrictions on material or thickness.

Effective for cutting thick and large-format glass sheets.

High cutting precision with tolerance controlled within ±0.2 mm.

High efficiency — cutting speed can reach 60–80 mm per second.

Diamond wheels gradually wear out at high speeds, requiring frequent inspection and replacement, which increases maintenance costs.

Limited shape flexibility: less efficient for irregular or complex geometries.

Potential surface risk: fine glass dust generated during cutting may cause minor surface scratches if not properly controlled.

Waterjet cutting—also known as hydrojet cutting—uses a high-pressure water stream to create a high-velocity jet that strikes the glass surface with tremendous impact to achieve cutting. For thicker or harder glass, fine abrasive particles such as aluminum oxide are added to the jet stream. The abrasive action of these particles enables precise material removal and clean separation. Key parameters that determine accuracy and efficiency include water pressure, nozzle diameter, and cutting speed.

Waterjet glass cutting relies on a waterjet machine and auxiliary systems to achieve non-contact, low-stress processing. The main components include a high-pressure pump, nozzle system, abrasive feeding system, and motion control platform.

The high-pressure pump generates a stable jet pressure typically ranging from 300–600 MPa, which can be adjusted according to glass hardness and thickness. The nozzle, made of wear-resistant ceramic, ensures a concentrated jet stream and high cutting precision. For thick or hard glass, abrasives such as aluminum oxide or quartz sand are mixed with the water stream to erode the surface efficiently.

The motion control platform ensures the glass moves smoothly along the programmed cutting path. CNC control allows precise straight, curved, and irregular cutting with tolerances up to ±0.1 mm. The support platform and clamps stabilize the glass, preventing vibration or sagging that could cause misalignment.

Operators must wear protective clothing, goggles, and waterproof gloves and be cautious of the high-pressure water jet and abrasive rebound. Waterjet cutting is ideal for irregular shapes or thick, brittle glass, especially when low thermal stress is required.

Non-contact cold cutting process with virtually no thermal stress.

Capable of processing thick and complex-shaped glass, supporting thicknesses from 1 to 40 mm with a tolerance of about ±0.5 mm.

Ideal for hard or brittle glass types; provides smooth cuts without deformation.

The process generates a significant amount of slurry and mist; improper control can cause surface scratches.

Edge quality is relatively rough and often requires post-grinding or polishing.

The operation environment is humid and noisy, requiring strict equipment maintenance and environmental management.

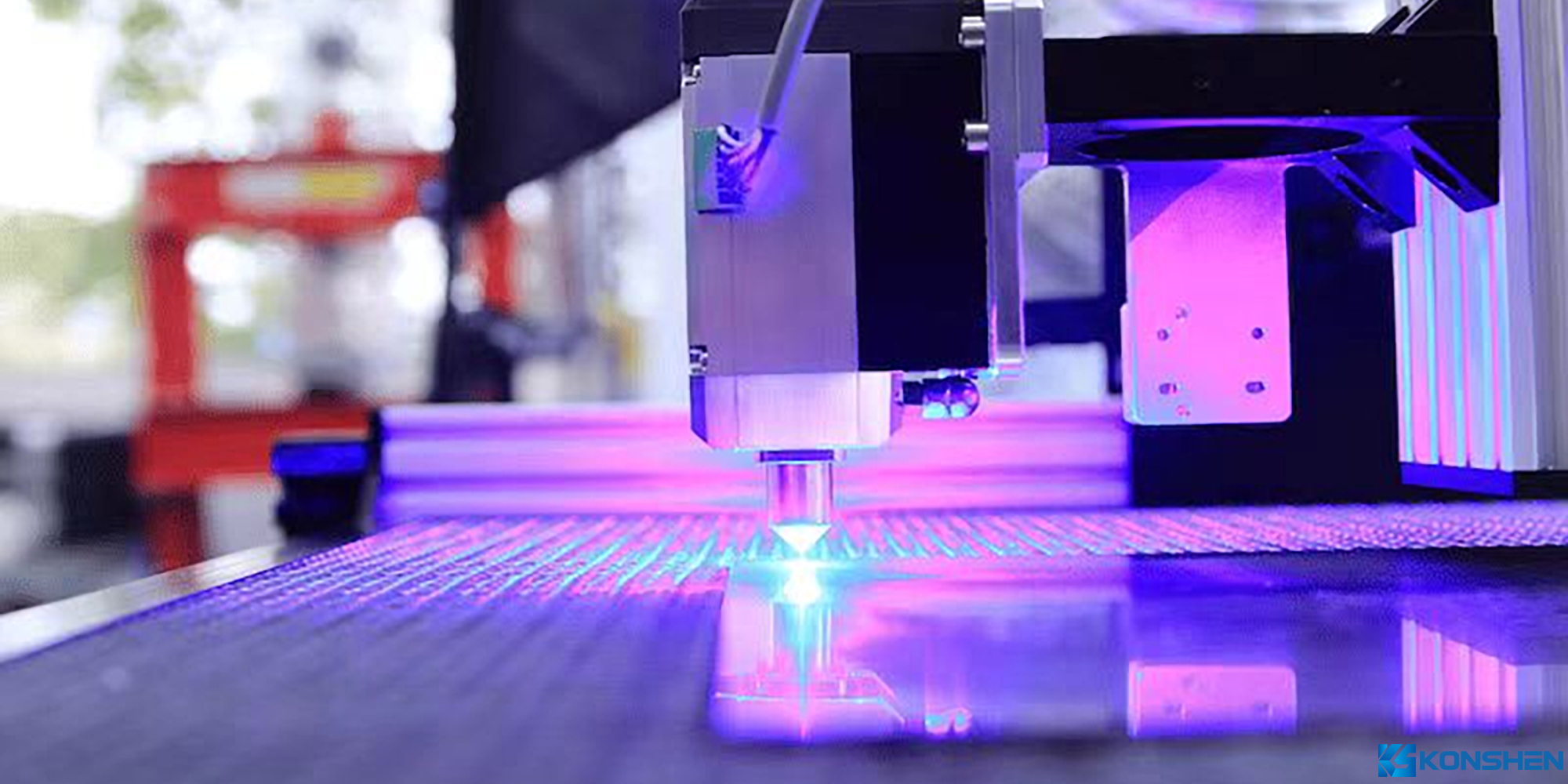

Laser cutting of glass is a non-contact technique that uses a high-energy-density laser beam to locally heat and control the fracture of the glass. Unlike traditional mechanical or waterjet methods, laser cutting achieves precise separation through thermal stress control and crack guidance. The resulting edges are clean, chip-free, and typically require no further polishing.

A laser cutting system typically consists of four main components: the laser generator, optical delivery system, cutting table, and CNC control system.

The laser generator can be configured for different glass types by selecting appropriate wavelength and power.

CO₂ lasers (10.6 μm) are suitable for most soda-lime and ultra-clear glass.

UV lasers (355 nm) are ideal for ultra-thin or precision optical components due to their short wavelength and minimal heat-affected zone.

The optical system, composed of mirrors and lenses, focuses the beam onto the glass surface, forming a small, high-energy spot that precisely scores or cuts the glass.

The cutting table often includes vacuum suction or mechanical clamps to stabilize the glass and prevent vibration or movement during processing.

The CNC control system regulates parameters such as laser power, scanning speed, focal length, and cutting path, enabling intricate and highly accurate cutting of complex shapes.

Laser cutting offers non-contact operation, low stress, and high precision, but requires a controlled environment with protective shielding, filtered viewing glass, and proper ventilation to prevent laser reflections and fume hazards.

This method is widely used in OLED display cover glass, precision optics, and ultra-thin specialty glass processing, valued for its clean edges and minimal micro-crack formation—ideal for high-end electronics and research equipment.

Non-contact cutting with no mechanical stress—ensures no surface damage.

Exceptional precision up to 0.001 mm, suitable for ultra-thin and optical-grade glass.

Capable of complex and irregular shapes with clean, low-defect edges.

High-speed operation, offering significantly better efficiency than traditional methods.

Cutting table size is limited, making it unsuitable for large-format architectural or industrial glass.

Only applicable to certain transparent glass materials, and thickness limitations apply.

High equipment and maintenance costs, requiring skilled operation and regular calibration.

Linear cutting of glass ingots is a high-temperature mechanical cutting process designed for bulk glass materials (ingots or large raw blocks) before forming or secondary processing. The process uses a mechanical cutter guided along a fixed linear rail to score the surface, followed by a controlled breaking force to achieve separation.

Because ingot glass is typically thick and uniform in size, the cutter pressure must remain even and the scribe line continuous. Some high-precision systems incorporate micro-vibration or ultrasonic assistance to improve scoring smoothness, thereby reducing edge micro-cracks and chipping.

This method relies on physical stress concentration at the scored line for clean fracture, avoiding thermal or chemical stress formation. It is widely used for optical glass, quartz glass, and borosilicate glass, particularly for precise dimensioning and pre-slicing of hard materials.

A linear glass ingot cutting machine typically consists of five main components: the cutting frame, linear rail system, scoring head assembly, breaking mechanism, control system, and worktable with clamping fixtures.

The linear rail system guides the cutting head along precision ball-screw or sliding rails, ensuring straightness and repeatability. Its high structural rigidity prevents deviation and provides accurate path control for consistent scoring.

The scoring head—the machine’s core unit—commonly uses a diamond or carbide-tipped wheel. Cutting pressure is precisely regulated by pneumatic or servo systems to maintain uniform force throughout the stroke. High-end systems may include micro-vibration or ultrasonic modules to reduce friction, enhance smoothness, and significantly minimize edge micro-cracks and chipping.

The breaking mechanism applies a controlled force after scoring to propagate cracks along the scribed line, achieving clean separation. Mechanical plates, rollers, or automated breaking systems may be used, with adjustable force and angle to ensure a neat break without secondary cracking.

The control system, usually CNC or PLC-based, manages parameters such as scoring speed, pressure, path, and breaking force. Some advanced systems integrate CCD vision inspection, automatically detecting edges and defects to optimize the cutting path and improve automation.

The worktable and clamping units stabilize the glass ingot using vacuum suction or mechanical fixtures, preventing any movement or vibration during operation.

Ideal for large and uniformly thick glass ingots requiring batch linear cutting.

Micro- or ultrasonic vibration assists in smoother scoring and reduces edge defects.

Generates no thermal or chemical stress, preserving the glass’s original optical and physical properties.

Easy equipment maintenance and reliable, safe operation.

Limited to straight-line or small-angle cuts; unsuitable for complex or irregular shapes.

Applicable only to pre-sizing of ingot glass, with relatively lower processing efficiency.

Requires high precision in pressure, rail alignment, and breaking force control—improper tuning may cause micro-cracks or chipping.

The quality of glass cutting directly affects subsequent processing, product performance, and safety. Therefore, establishing a strict quality control and inspection system is essential. Quality management covers not only dimensional accuracy, edge integrity, and surface finish, but also process stability and operational consistency.

GB 11614-2009 “Flat Glass”

This standard specifies requirements for dimensional accuracy, thickness tolerance, and edge quality of flat glass. Slight edge chipping is permissible, but no visible cracks, notches, or detached fragments are allowed. Surface defects such as scratches, bubbles, or inclusions that affect mechanical processing or appearance are prohibited. Example: For float glass with a thickness of 3–10 mm, the allowable thickness deviation is ±0.2 mm; the tolerance increases proportionally with larger glass sizes.

GB 9656-2016 “Safety Glass for Buildings”

This standard imposes stricter requirements on the edge quality of tempered, laminated, and insulating glass. Edges must be flat and free from sharp cracks to ensure safety. Minor edge chipping is acceptable but must be eliminated through grinding or chamfering to meet safety criteria.

GB/T 15763.2-2005 “Optical Glass and Optical Components”

For optical glass, the standard limits the allowable length and width of micro-cracks along the cutting edge to preserve surface integrity and ensure optical performance.

In general, Chinese GB standards specify clear numerical limits for cutting precision and edge integrity, while also defining quality grades according to end-use categories such as architectural, industrial, or optical applications.

International standards also set detailed requirements for glass cutting quality, particularly for architectural, display, and optical applications:

ISO 12543-1 Glass in Building Laminated Glass and Laminated Safety Glass

Defines dimensional and edge quality standards, allowing minimal chipping while limiting micro-crack length and notch depth. For optical glass, the cut surface must meet transmission and reflection criteria to maintain optical performance.

ASTM C1048 Standard Specification for Heat-Strengthened and Fully Tempered Flat Glass

Applies to heat-strengthened and tempered flat glass. For thicknesses under 12 mm (½ in.), dimensional tolerances for holes, notches, and cutouts are ±1.6 mm (±1⁄16 in.). The standard emphasizes that edges must be smooth, free of visible cracks or notches.

EN 572-2 Glass in Building -Float Glass

Specifies size tolerances, allowable edge defects, and surface quality levels for both straight and shaped cuts. Edge completeness and micro-crack limits are strictly defined.

Overall, international standards place strong emphasis on edge integrity and micro-crack control, particularly for high-end applications such as optics and displays, where precision, smoothness, and surface cleanliness are essential to performance.

The final quality of glass cutting depends not only on the cutting method but also on multiple influencing factors such as material properties, equipment precision, process parameters, operator technique, and environmental conditions. Improper control of any single factor can result in edge chipping, dimensional deviation, or stress concentration defects.

The chemical composition, thickness, density, and internal stress of glass significantly affect its cuttability.

Hardness and brittleness: Glasses with high silicon or alumina content are harder and more brittle, prone to micro-cracks during cutting. Lower pressure and high-precision tools are required.

Thickness: Thicker glass concentrates more stress along the cutting line, requiring enhanced cooling and controlled breaking systems.

The sharpness of the tool, wheel diameter, rail precision, and cutting speed control all determine the cut quality.

Tool wear: Dull wheels or laser focus degradation result in discontinuous cutting lines and rough edges.

Rails and fixtures: Any deviation in rail straightness or unstable clamping causes vibration and curved cutting paths.

Cooling system: Uneven coolant temperature or flow generates localized thermal stress, leading to micro-cracks along the cut.

Proper coordination between cutting pressure, speed, temperature, and scoring depth is crucial.

Excessive pressure causes deep scratches and chipping, while insufficient pressure produces incomplete scribing.

Overly high speed prevents full stress release; too slow results in overheating or surface melting.

In laser cutting, the balance between laser power and focal distance determines the size of the heat-affected zone and the smoothness of the cut edge.

Operator skill and ambient conditions (humidity and cleanliness) also play important roles.

Skill level: Experienced operators can adjust force and speed to match the glass type, reducing scrap rate.

Humidity and temperature: Low humidity increases static electricity, attracting dust; high temperature causes thermal expansion and edge deformation.

Cleanliness: Dust or oil on the surface interferes with tool contact, leading to deviation or uneven breaks.

3.3 Common Cutting Defects and Optimization Methods

Common cutting defects in glass include edge chipping, micro-cracks, dimensional deviation, scratches, and thermal deformation. These issues can reduce mechanical strength, compromise appearance, and affect downstream processing. Optimizing process parameters, equipment setup, and environmental conditions can significantly improve cutting quality and yield.

| Defect Type | Cause | Optimization |

| Edge Chipping |

|

|

| Micro-Cracks |

|

|

| Dimensional Deviation |

|

|

| Surface Scratches and Damage |

|

|

| Thermal Stress Deformation |

|

|

Glass cutting is not only a critical technical process but also a major cost factor influencing overall profitability. Accurate cost accounting must consider multiple dimensions, including raw material loss, cutting efficiency, equipment depreciation, labor cost, and scrap rate. By optimizing cutting workflow and process parameters, manufacturers can significantly improve productivity and reduce total cost.

The cost of glass cutting generally consists of five main components:

Raw Material Cost

Includes the price of glass substrates, transportation, and storage. Layout design and material utilization rate directly affect material waste.

Processing Cost

Determined by the cutting method (manual, waterjet, laser, etc.), covering energy consumption, tool wear, and coolant usage. While laser cutting provides higher precision, it incurs greater energy and maintenance costs; mechanical and waterjet cutting offer cost advantages for large-scale production.

Equipment Depreciation

High-precision cutting machines are capital-intensive, with typical depreciation periods of 5–8 years. Depreciation is allocated per production batch based on usage life.

Labor and Management Cost

Covers operator wages, training, and management expenses. Increasing automation can effectively reduce labor proportion in total cost.

Scrap and Rework Cost

Defects caused by cutting errors, stress cracks, or chipping can greatly increase unit cost. Improving yield rate is thus critical to cost optimization.

In glass production, yield and scrap rate are calculated as follows:

Yield Rate=(Number of Qualified Products÷Total Input)×100%

Scrap Rate=(Number of Scrapped Items÷Total Input)×100%

In most glass processing plants, the cutting yield rate generally ranges between 90% and 97%.

For ultra-thin or irregularly shaped glass, however, the rate may drop to 85%–90% due to uneven internal stress and the difficulty of fracture control.

A lower yield not only results in direct material loss but also increases the cost of subsequent polishing, edging, and cleaning processes.

Optimize Layout and Material Nesting

Use CNC layout or CAD/CAM systems to maximize material utilization and minimize offcut waste.

Select the Appropriate Cutting Method

Choose the optimal method based on product type and glass thickness. Laser cutting suits high-precision parts; waterjet cutting is ideal for thick or complex shapes; diamond cutting offers high cost-effectiveness.

Increase Automation

Implement automatic loading, intelligent inspection, and online monitoring to reduce human error and scrap rate.

Maintain Equipment and Tools

Regularly inspect wheel wear and rail alignment to ensure stable machine performance, extending lifespan and maintaining precision.

Refine Process Parameter Control

Establish a parameter database to automatically match pressure, speed, and cooling settings for different glass types, reducing trial-cutting costs.

The glass cutting process directly affects the safety of operators and the environmental standards of the production site. Strict safety regulations and environmental measures not only reduce the risk of workplace injuries but also help enterprises achieve green production and sustainable development.

Glass is fragile during cutting, handling, and subsequent processing, and its edges are sharp, posing significant risks to operators. Therefore, establishing comprehensive safety operating procedures is crucial.

Key safety measures include:

Personal Protective Equipment (PPE): Operators must wear cut-resistant gloves, safety glasses, protective clothing, and safety shoes to prevent injuries from sharp glass edges.

Training and Skill Assessment: Employees should receive training in glass cutting processes, equipment operation, and emergency handling, with periodic assessments to ensure safe operation practices are mastered.

Equipment Safety Measures: Cutting machines, laser cutters, and water jet cutters should be equipped with protective shields or safety barriers to prevent glass shards from causing injury.

Handling and Support Guidelines: When moving glass, suction cups, clamps, or racks should be used instead of manual handling of large panels. Supporting platforms should be stable and level.

Emergency Response Plans: Enterprises should develop procedures for handling broken glass, promptly clean up debris, provide first-aid kits, and train staff to manage cuts or other accidents.

Glass cutting generates dust, wastewater, and noise, which can affect both the environment and operator health, particularly during water cutting and mechanical edge grinding processes.

Environmental protection measures include:

Dust Control: Use dust collection systems and localized extraction devices to capture glass dust generated during cutting or grinding and prevent dispersion.

Wastewater Treatment: Wastewater from water cutting containing glass particles should be treated through sedimentation, filtration, and recycling systems to minimize water waste and environmental pollution.

Noise Control: Cutting machines and laser systems should be equipped with soundproof covers or operated in soundproof rooms to reduce noise exposure to workers and surrounding areas.

Waste Material Recycling: Scrap, glass offcuts, and fragments should be collected for reprocessing or recycling to reduce material waste and environmental burden.

The concept of green production is increasingly important in the glass processing industry. Proper energy-saving measures not only reduce production costs but also support sustainable development.

Energy-saving measures include:

Optimizing Process Parameters: Select the optimal cutting speed, pressure, and power according to glass thickness and type to reduce energy consumption.

Automated Cutting Systems: Use CNC equipment to optimize nesting and cutting paths, improving efficiency and reducing repeated operations and material waste.

Equipment Maintenance: Regularly maintain cutting machines, pumps, and laser systems to ensure high-efficiency operation and lower power consumption.

Reuse and Recycling: Cutting water, abrasives, and glass offcuts can be recycled, reducing consumption and environmental impact.

By implementing strict safety regulations, dust and wastewater control, and energy-saving measures, enterprises can ensure glass cutting quality and efficiency while protecting operator safety, reducing environmental impact, and achieving green, sustainable production.

With technological advances and increasing market demand, glass cutting processes are undergoing significant changes. Future trends involve not only upgrades in cutting technology but also the widespread adoption of automation, intelligence, and green production concepts.

Smart Manufacturing: CNC cutting systems, automatic nesting software, and intelligent monitoring devices will be widely used, enabling automatic adjustment of cutting precision, alarm for abnormalities, and quality tracking. Reduced manual intervention will greatly improve production efficiency and yield.

Data-Driven Process Optimization: Through big data analysis and machine learning, production parameters can be automatically optimized based on glass type, thickness, and historical process data, reducing scrap and cutting losses.

Green Production: Energy saving and environmental protection measures will become standard. Technologies such as water recycling, offcut reprocessing, and dust collection and filtration will gradually become widespread, promoting a low-carbon and eco-friendly industry.

High-Yield Cutting: By combining advanced cutting technology, intelligent monitoring, and optimized nesting, cutting yield will continuously improve. This is especially significant for high-end display glass, optical glass, and ultra-thin glass, where high yield can significantly reduce production costs and material waste.

Glass cutting is a crucial step in glass processing, directly affecting dimensional accuracy, edge quality, and safety. Selecting the right method based on glass type and application, adhering to standards, optimizing processes, and maintaining safety and environmental measures ensures high-quality, cost-effective, and sustainable production. Future trends focus on higher precision, automation, and green practices.

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us