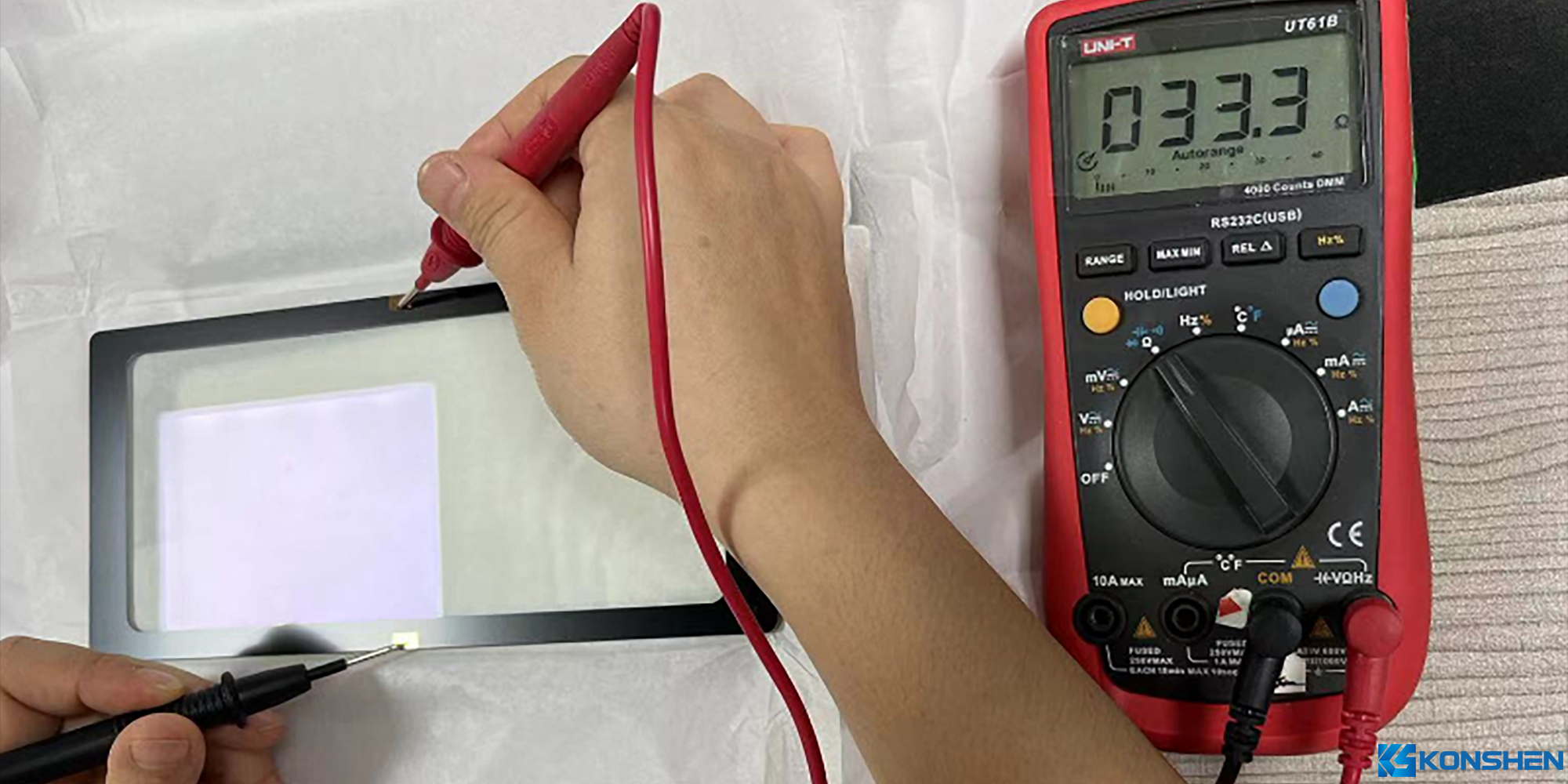

ITO (Indium Tin Oxide) is a transparent conductive oxide (TCO) material widely used in touch panels, displays, solar cells, sensors, and transparent electrodes.

To create electrodes, wiring, or microstructures, the continuous ITO layer must be partially removed in specific regions — a process known as etching.

Different etching techniques (laser, dry, or wet) each have unique strengths and weaknesses in terms of precision, cost, environmental impact, and throughput. Selecting the right method directly affects your product yield, quality, and cost efficiency.

Laser etching removes the ITO film using focused high-energy laser pulses, which trigger localized photothermal or photochemical effects (vaporization, delamination, or modification).

Depending on the pulse duration and wavelength, lasers can be classified as nanosecond (ns), picosecond (ps), or femtosecond (fs) types.

Ultra-short pulses (ps/fs) achieve “cold” ablation with minimal heat damage, while longer ns pulses may introduce thermal diffusion and substrate stress.

Key parameters include wavelength, pulse width, fluence (energy density), repetition rate, and scan speed.

Femtosecond and picosecond lasers can remove ITO precisely with minimal substrate damage.

Nanosecond lasers can offer higher absorption efficiency but usually produce larger heat-affected zones (HAZ).

Parameter selection depends on ITO film thickness, substrate type (glass vs. PET), and target linewidth.

Laser etching is ideal for rapid prototyping, low-volume, and mask-free production where flexibility is key.

However, redeposited particles, carbonization, or splatter may occur. It’s recommended to apply plasma or chemical cleaning after etching to restore the film’s optical and electrical performance.

Maskless, flexible, and non-contact process.

Compatible with flexible substrates and complex designs.

Environmentally friendly (no liquid chemical waste).

Low throughput for large-scale manufacturing.

High equipment cost, especially for ultrafast lasers.

Possible thermal damage if parameters are not optimized.

Dry etching removes ITO through plasma discharge in a vacuum chamber. Reactive ions and radicals physically and chemically interact with ITO, breaking down and removing the film.

Typical gas chemistries include Cl₂, BCl₃, SiCl₄, Ar, and more recently Ar/H₂ “green” processes, which reduce harmful by-products.

Dry etching provides excellent anisotropy, meaning more vertical sidewalls and higher precision than wet etching.

Halogen gases (Cl₂, BCl₃, SiCl₄) produce volatile indium or tin chlorides that accelerate the etch rate.

Inert gases (Ar, He) improve physical sputtering and surface morphology.

Green alternatives like Ar + H₂ mixtures help reduce environmental impact without compromising etch performance.

Etching performance depends on RF/ICP power, substrate bias voltage, pressure, and temperature.

Higher bias voltage increases ion energy but can cause surface damage if excessive.

Dry etching excels at micro-scale structures with superior vertical sidewalls and consistent repeatability, but comes with higher operational cost.

Advantages:

High resolution and excellent anisotropy.

Compatible with semiconductor and optoelectronic fabrication lines.

High reproducibility for mass production.

Limitations:

High equipment investment and maintenance.

Some chemistries involve toxic or corrosive gases.

Large glass panels require advanced fixture systems to ensure uniformity.

Wet etching uses acidic or complexing solutions to dissolve or oxidize the ITO layer.

This method typically involves photolithography to define patterns:

Coating → Exposure → Development → Chemical Etching → Resist Removal → Cleaning

Common etchants include HCl, HCl + HNO₃, FeCl₃, and oxalic acid.

Etch rate depends on concentration, temperature, agitation, and ITO composition.

Raising temperature significantly accelerates etching but also increases lateral etching (undercut).

Proper waste neutralization and operator safety are essential in mass production.

Mature and cost-effective process.

Low equipment cost and easy implementation.

Suitable for large-area glass panel production (e.g., displays).

Limited resolution due to undercut.

Acid waste requires strict environmental management.

Not ideal for micro-scale or high-precision applications.

|

Application Scenario |

Recommended Method |

Reason |

|

Rapid prototyping / small batch / custom patterns |

Laser etching |

Mask-free, fast iteration |

|

Fine lines / vertical sidewalls / microelectronics integration |

Dry etching (RIE/ICP) |

High anisotropy and repeatability |

|

Large-area, cost-sensitive mass production |

Wet etching |

Lowest cost per area, mature process |

|

Flexible substrates (PET, ultra-thin glass) |

Femtosecond or low-temp dry etch |

Prevents heat deformation or warping |

Each method serves a unique purpose — optimizing cost, speed, precision, and environmental performance requires balancing these trade-offs.

ITO film thickness & composition (In:Sn ratio):

Impacts etch rate, energy settings, and residual conductivity

Minimum line width & edge quality:

Wet etch has undercut issues; dry/laser methods provide sharper edges.

Substrate damage inspection:

Check for micro-cracks or stress after laser; residual contamination after dry etch.

Environmental & safety compliance:

Wet etch requires acid neutralization systems; dry etch needs gas scrubbing; laser etching needs optical and fume safety measures.

6. Practical Insights from Industry and Research

BCl₃/Cl₂ (ICP) recipes show etch rates exceeding 100 nm/min with smooth sidewalls — ideal for dense microstructures.

Femtosecond and picosecond lasers can remove ITO without damaging glass substrates, preserving optical performance.

Oxalic acid wet etch offers smooth surfaces but slower etch rates, suitable for high-surface-quality applications.

A: It depends on laser energy and pulse mode. Properly tuned ultrashort pulses remove ITO cleanly with minimal substrate damage. Overexposure may cause oxidation, carbonization, or cracks that affect conductivity.

Q2. How to reduce undercut in wet etching?A: Improve photoresist coverage and adhesion, reduce temperature, shorten etch time, or switch to dry etching for better vertical profiles.

Q3. Are there more eco-friendly etching methods for ITO?A: Yes. Emerging Ar + H₂ plasma etching avoids harmful halogen gases. Laser etching is also considered an environmentally friendly alternative since it produces no liquid waste.

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us