Content:

Introduction

1. IK Rating: The Safety Score for Cover Glass Protection

1.1 What is the IK Rating?

1.2 How is the IK Rating Tested?

1.3 Relationship with Familiar Standards

2. Glass Thickness and Protection

2.1 Core Matching Rule: Thickness as the Foundation

2.2 Cover Glass Materials: Thin Glass with High Protection

2.3 Clarifying Common Misconceptions: Thicker Glass doesn't mean Safer

3. Cover Glass Processes and Technologies

3.1 Tempering Processes

3.2 Surface Coatings

4. Scenario-Based Selection

4.1 Daily Electronic Devices

4.2 Outdoor Public Facilities

4.3 Industrial and Architectural Applications

4.4 Extreme Environments

Conclusion

Introduction

When picking up your phone, have you ever wondered why the 1.2mm-thick screen glass can withstand daily drops? When walking into a shopping mall, how do the glass panels of outdoor equipment endure crowds' collisions? In these scenarios, the unsung hero safeguarding device safety is Cover Glass, and the core standard for measuring its protective capacity — the IK Rating System — has long permeated every aspect of our lives.

According to data from the China Architectural and Industrial Glass Association, 30% of electronic device failures and 45% of architectural glass safety accidents result from impact-induced breakage. From mobile phone screens to skyscraper curtain walls, from charging pile panels to hospital protective windows, the impact resistance of Cover Glass directly determines product lifespan and usage safety. This article will decode the mysteries of the IK Rating System, reveal the matching rules between glass thickness and protective capacity, and explain the scientific principles behind "thin glass shatter resistance" and "thick glass explosion protection."

1.IK Rating: The Safety Score for Cover Glass Protection

1.1 What is the IK Rating?

The IK Rating (Impact Protection Rating) is a mechanical impact protection standard formulated by the International Electrotechnical Commission (IEC) (corresponding to Chinese national standard GB/T 20138-2021). It acts like a "safety score" for glass — ranging from IK00 (no protection) to IK10 (highest protection), totaling 11 levels. The higher the level, the stronger the impact resistance.

| IK Rating |

Impact Energy (J) |

Test Method |

Typical Impact Scenario |

Corresponding Minimum Thickness (mm) |

|

IK05

|

0.9

|

Mechanical Impact with 1.7kg Impact Hammer

|

Daily Minor Collisions

|

1.0 (Soda-Lime Glass)

|

|

IK06

|

1.2

|

Mechanical Impact Test

|

Moderate Impacts in Commercial Environments

|

2.0 (Soda-Lime Glass)

|

|

IK07

|

1.7

|

Mechanical Impact Test

|

Light Impacts in Industrial Environments

|

3.0 (Aluminosilicate Glass)

|

|

IK08

|

5.0

|

Ball Drop Test (500g Steel Ball, 1m Drop Height)

|

High-Frequency Impacts on Outdoor Equipment

|

4.0 (Tempered Glass)

|

|

IK09

|

10.0

|

Ball Drop Test (1kg Steel Ball, 1m Drop Height)

|

Heavy Industrial Collisions

|

5.0 (Chemically Tempered Glass)

|

|

IK10

|

20.0

|

Ball Drop Test (1kg Steel Ball, 2m Drop Height)

|

Extreme Impact Environments

|

6.0 (Chemically Tempered Glass)

|

Note: The Ball Drop Test is the mainstream verification method in the industry (Reshine Display 2024 Actual Test Data). Test environment requirements: Temperature 23±5℃, Humidity 50±10%. Samples must undergo 24-hour constant temperature and humidity conditioning prior to testing.

1.2 How is the IK Rating Tested?

Professional testing institutions conduct tests in strict accordance with standardized procedures:

1. Prepare 3 or more standard-sized samples (at least 100mm×100mm) and condition them at 23℃ and 50% humidity for 24 hours in advance;

2. Use impact hammers or steel balls of specified weights to freely fall from specific heights and impact vulnerable parts of the glass, such as surfaces and edges;

3. A sample is deemed qualified for the rating if it shows no penetrating cracks or fragment detachment.

Notably, test results depend not only on thickness but also on glass material and manufacturing processes. For instance, 3mm-thick ordinary soda-lime glass may only reach IK06, while chemically tempered aluminosilicate glass can achieve IK08.

1.3 Relationship with Familiar Standards

You may be familiar with the IP Rating (Ingress Protection for dust and water), such as IP68 for mobile phones. The IK Rating is a dedicated impact resistance score, and the two can be used in combination. For example, the panels of outdoor charging piles are often marked "IP66/IK10," meaning "fully dustproof, rainproof, and capable of withstanding heavy impacts."

In the construction field, Australia's AS2208 certification stipulates that curtain wall glass in high-density public areas such as schools and hospitals must reach IK10 with a thickness of no less than 8mm.

2. Glass Thickness and Protection

2.1 Core Matching Rule: Thickness as the Foundation

Thickness is a key factor affecting the IK Rating, but "thicker is not always better" — there are clear matching rules. Based on actual test data, the corresponding relationship between mainstream glass thickness and IK Rating is as follows:

-

1.0-2.0mm: Ordinary soda-lime glass, corresponding to IK05-IK06. Commonly used in low-end electronic devices, it may crack from minor daily collisions;

-

2.0-3.0mm: Aluminosilicate glass, corresponding to IK07. For example, early smartphone screens can resist daily scratches from keys and coins;

-

4.0-5.0mm: Tempered aluminosilicate glass, corresponding to IK08-IK09. Used in outdoor equipment and charging piles, it can withstand moderate impacts from handbags, tools, etc.;

-

6.0mm and above: Chemically tempered glass, stably reaching IK10. Suitable for architectural curtain walls and industrial control cabinets, it can resist hammer blows and falling heavy objects.

Key Data: For every 1mm increase in thickness, impact strength increases by an average of 15-20%. However, beyond 12mm, the growth rate drops to 8-10% — for example, the impact resistance of 12mm glass is not twice that of 6mm glass, which is known as the "marginal effect of thickness."

2.2 Cover Glass Materials: Thin Glass with High Protection

Why can some mobile phone glasses (only 1.2mm thick) resist drops from 1.2 meters? The secret lies in materials and manufacturing processes. There are 4 common Cover Glass materials, with vastly different protective capabilities:

-

Soda-lime glass: The most basic type. 1.1mm-thick soda-lime glass only reaches IK06. Low-cost but fragile, it is mainly used in doors, windows, and low-end devices;

-

Aluminosilicate glass: The mainstream mid-to-high-end material (e.g., Corning Gorilla Glass). 1.8mm-thick chemically tempered aluminosilicate glass can reach IK08, with drop resistance 5 times that of ordinary glass;

-

Ceramic Shield glass: Used in Apple iPhone 12 and later models. Embedded with nano-ceramic crystals, 2.0mm-thick Ceramic Shield glass achieves IK09, with shatter resistance twice that of ordinary aluminosilicate glass;

-

Glass-ceramic: Contains a large number of nano-crystals. 3.0mm-thick glass-ceramic can reach IK10, with impact resistance 10 times that of ordinary glass, but its cost is extremely high.

2.3 Clarifying Common Misconceptions: Thicker Glass doesn't mean Safer

Many people believe thicker glass is safer, but the actual situation is:

-

For glass thicker than 25mm, the improvement in impact resistance is limited, and additional steel structure reinforcement is required, increasing the overall cost by 30%;

-

Simply increasing thickness is less effective than the "thickness + process" combination: For example, 6mm chemically tempered glass offers far better protection than 10mm ordinary tempered glass;

-

Edge design is more critical: Chamfering the glass edges by 2mm or more can reduce stress concentration, increasing the IK Rating by 1 level.

3. Cover Glass Processes and Technologies

3.1 Tempering Processes

Tempering processes can double glass strength, mainly divided into two types:

-

Chemical tempering: Through ion exchange technology, a compressive stress layer is formed on the glass surface (strength up to 600MPa), increasing the IK Rating by 1-2 levels for the same thickness. For example, 3mm aluminosilicate glass only reaches IK07 without tempering, but can achieve IK09 after chemical tempering;

-

Physical tempering: Heating to high temperatures followed by rapid cooling, resulting in a surface compressive stress of approximately 300MPa. 3mm glass can only reach IK08 with physical tempering, and its flatness is poor, making it suitable for scenarios with low optical performance requirements.

3.2 Surface Coatings

Surface treatments can further enhance protective capabilities:

-

AF anti-fingerprint coating: Not only resists oil stains but also increases surface hardness to 7H, raising the IK Rating of 2mm glass from IK07 to IK08;

-

Nano-coating: Forms a dense protective layer through chemical vapor deposition (CVD) technology, improving impact resistance by 50%. 2.5mm glass with nano-coating can achieve IK09;

-

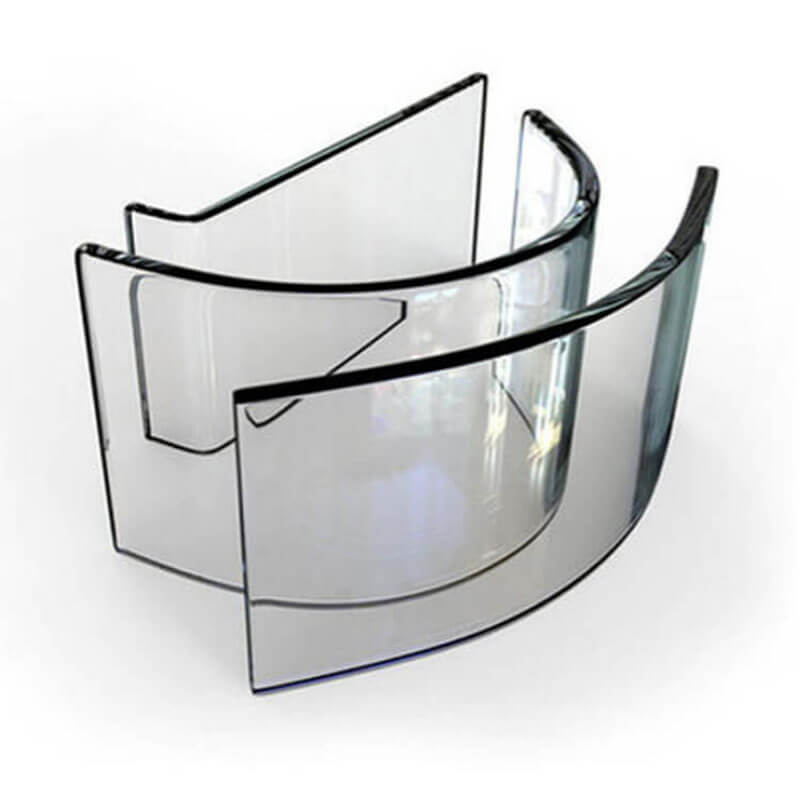

Laminated technology: Bonding two layers of glass with PVB (Polyvinyl Butyral) or SGP (SentryGlas Plus) film. Even if broken, the glass will not splinter. Commonly used in architectural curtain walls, 8mm laminated glass stably reaches IK10.

4. Scenario-Based Selection

4.1 Daily Electronic Devices

Requirement: Thin, lightweight + daily protection (IK06-IK08);

Recommendation: 1.2-1.8mm chemically tempered aluminosilicate glass (e.g., Gorilla Glass GG6). Suitable for mobile phones and tablets, it can resist drops from within 1 meter and scratches from keys.

4.2 Outdoor Public Facilities

Requirement: Weather resistance + collision resistance (IK09);

Recommendation: 3.0-4.0mm nano-composite glass + AR coating. Suitable for outdoor kiosks and charging piles, it can withstand rain, ultraviolet radiation, and malicious collisions.

4.3 Industrial and Architectural Applications

4.3 Industrial and Architectural Applications

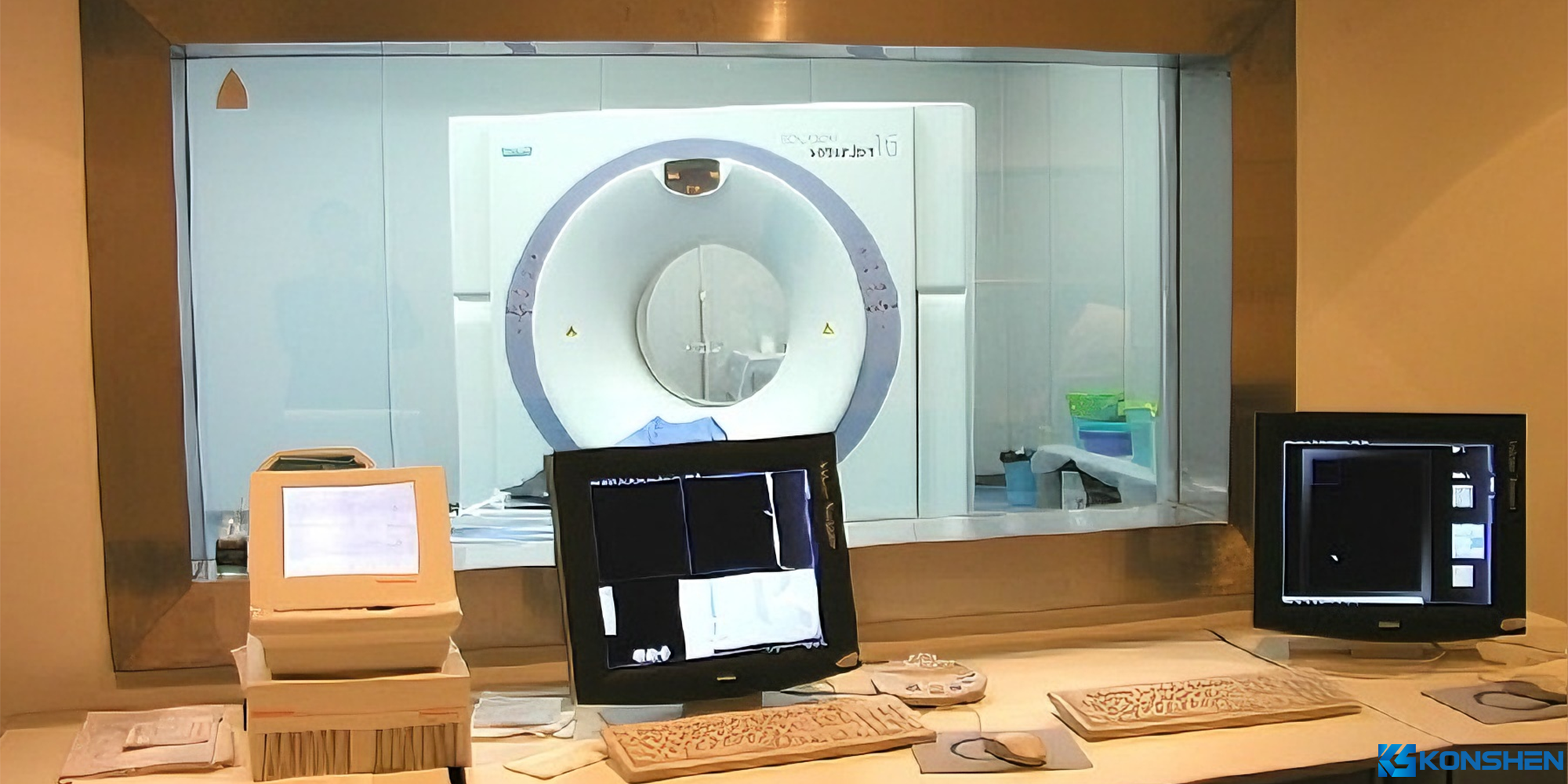

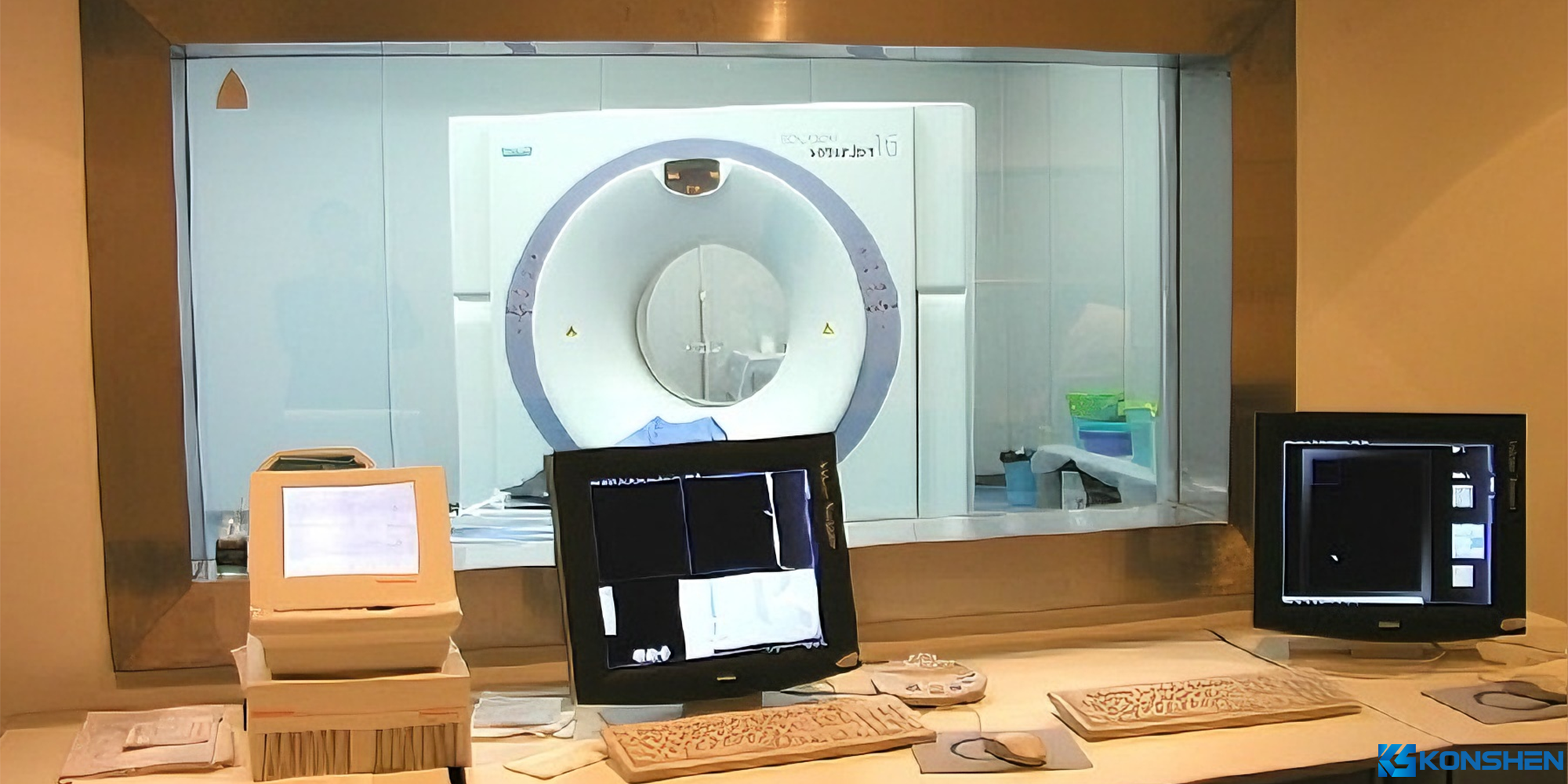

Requirement: Explosion protection + safety (IK10);

Recommendation: ≥6.0mm chemically tempered glass (industrial) and ≥8.0mm laminated glass (architectural). Suitable for industrial control cabinets and hospital curtain walls, it can resist heavy object impacts and falling debris from heights.

4.4 Extreme Environments

Requirement: Super high protection (IK10-IK12);

Recommendation: 6.0-8.0mm lithium aluminosilicate glass (double tempering). Suitable for polar equipment and military products, lithium aluminosilicate glass has a flexural strength of up to 1700MPa, 1.5 times that of ordinary aluminosilicate glass.

Conclusion

The IK Rating System provides a unified standard for the protective performance of Cover Glass, and the scientific matching of thickness with materials and processes is the key to achieving a "balance between safety and cost-effectiveness." From mobile phone screens to skyscrapers, from daily use to extreme environments, understanding this knowledge not only helps us select more durable products but also allows us to appreciate the charm of materials science — behind a small piece of glass lies countless precise calculations about strength, thickness, and safety.

In the future, with the development of nanotechnology and composite materials, we may see 0.5mm-thick glass resisting drops from 2 meters or even self-repairing damage. The IK Rating System will continue to serve as a safety ruler, guarding every aspect of our lives.

Coated GlassElevate your projects with advanced coated glass solutions from KS Glass.

Coated GlassElevate your projects with advanced coated glass solutions from KS Glass. Cover GlassUpgrade your devices with our cover glass.

Cover GlassUpgrade your devices with our cover glass. Solar Panel GlassUpgrade your devices with our cover glass.

Solar Panel GlassUpgrade your devices with our cover glass. Glass MaterialDiscover the endless possibilities of working with large glass material.

Glass MaterialDiscover the endless possibilities of working with large glass material.

4.3 Industrial and Architectural Applications

4.3 Industrial and Architectural Applications