Key Features:

Ultra-Thin 0.5mm Profile: The glass sheet is manufactured with a precise 0.5mm thickness, making it ideal for compact and lightweight applications where dimensional accuracy and minimal bulk are essential.

Premium SCHOTT BF33 Material: Crafted from original SCHOTT BF33 borosilicate glass, this material offers exceptional chemical resistance, high thermal stability, and excellent optical clarity, ensuring long-term reliability in harsh environments.

High Thermal Resistance: With a softening point of approximately 820°C and a low coefficient of thermal expansion (3.3 × 10⁻⁶ /K), BF33 glass maintains stability under rapid temperature changes, making it suitable for thermal processing and laboratory conditions.

Excellent Optical Clarity: BF33 glass has high light transmittance (up to 92% in visible range) and low autofluorescence, making it perfect for optical windows, sensors, and analytical instruments that require accurate light transmission and minimal distortion.

Strong Chemical Durability: The glass offers outstanding resistance to water, acids, alkalis, and organic solvents, allowing it to be used in demanding chemical and biomedical environments without degradation or surface damage.

High Surface Quality & Precision Machining: Our BF33 glass undergoes precision cutting, edge polishing, and quality control to meet stringent industry standards. Optional customization includes drilled holes, edge grinding, and surface coating for specific application needs.

Versatile Applications: Widely used in scientific research, microfluidic devices, high-end displays, and analytical instruments, this glass supports a wide range of industries from electronics and optoelectronics to medical diagnostics.

Customized Option:

Available Thickness: Ranging from 0.2 mm to 15 mm, depending on the insulation requirements and specific applications.

Size & Shape: Supports special-shaped cutting to meet diverse needs. Customizes as per drawing.

Cutting Option: CNC Cutting/Water jet Cutting/Diamond Blade Cutting

Edge Options: Polished Edge/Safety Edge/Beveled Edge/Smooth Edge/2.5D Edge/Pencil Edge/Straight Edge

Coating Options: Anti-Reflective (AR) Coating/Anti-Fingerprint (AF) Coating/Scratch-Resistant Coating/Indium Tin Oxide(ITO) Coating or Anti-Glare (AG)Coating

Materials: SCHOTT BF33 Borosilicate Glass

Shape: Round

Thickness: 0.5mmT

Diameter: 100mm

Edge Work: Safety edge by CNC machine

Density: 2.23 g/cm³

Thermal Expansion Coefficient: 3.3 × 10⁻⁶ /K

Softening Point: ~821°C

Annealing Point: ~560°C

Strain Point: ~518°C

Refractive Index (nd): 1.47

Young's Modulus: ~64 GPa

Chemical Resistance: High

Flatness: ≤λ/4 (customizable)

Poisson's Ratio: 0.2

Hardness (Mohs): ~6.5

Surface Roughness (Ra): <10 nm (optically polished)

Electrical Resistivity: 10¹³–10¹⁴ Ω·cm

Birefringence: Very low

Surface Quality: 60/40, better options available

Visible Light Transmission: ~92% @ Visible Spectrum (400–700nm)

UV Cut-off Wavelength: ~300 nm

Operating Temperature Range: Suitable for -30°C to 250°C.

Thickness Tolerances:± 0.05mm

Dimensional Tolerances:±0.5mm for large size; ±0.1mm for small size.

Laboratory & Scientific Equipment: With excellent thermal stability and chemical resistance, BF33 glass is ideal for lab slides, viewports, microfluidic chips, and container covers used in biological, materials, and physical science research.

Optical Windows & Laser Systems: The high transmittance and minimal birefringence of BF33 make it an excellent choice for optical windows, IR filters, and laser system front panels—ensuring clean and accurate light transmission.

Display & Sensor Modules: Used in sensor windows, display covers, and camera module glass, this material supports high optical clarity and structural reliability in compact electronic devices.

Medical Imaging & Diagnostic Devices: Employed in medical analyzers, diagnostic windows, and sample imaging devices, BF33 offers excellent optical clarity, anti-fouling surface, and chemical resistance for hygienic environments.

AR/AF Coating Substrates: Due to its excellent surface quality and optical uniformity, BF33 is widely used as a substrate for AR/AF coatings in aerospace, defense optics, and high-end display applications.

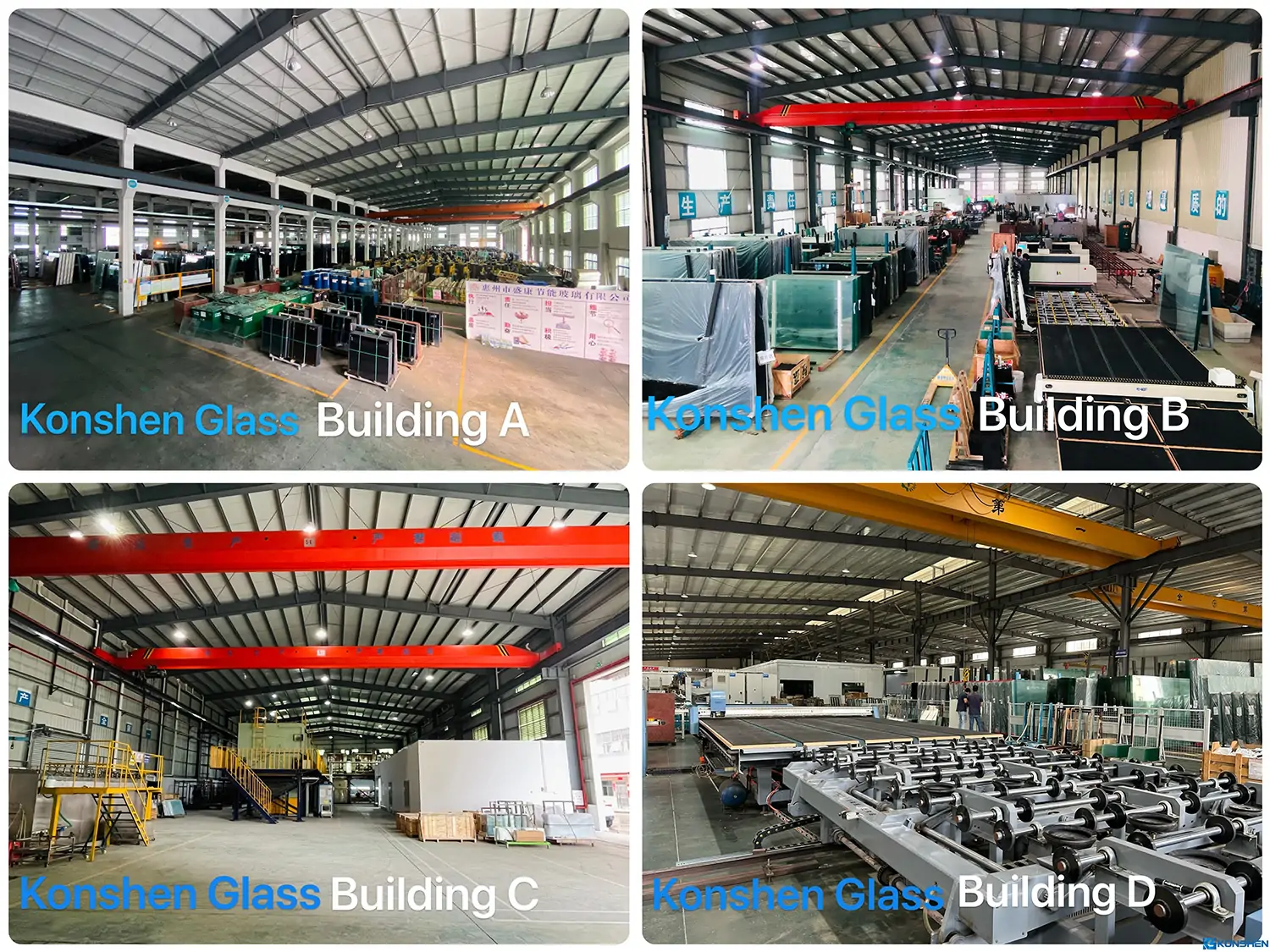

Customer Visit

Company Profile

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us