| Common Model: | Corning Gorilla Glass 3/Corning Gorilla Glass 5/Corning Gorilla Glass Victus/Corning Eagle XG | |||

| Thickness Options: | Available thickness ranging from 0.4 mm to 2.0 mm | |||

| Cutting Option: | Laser Cutting/CNC Cutting/Water jet Cutting/Diamond Blade Cutting | |||

| Edge Work: | Polished Edge/Safety Edge/Beveled Edge/Smooth Edge/2.5D Edge/Pencil Edge/Straight Edge | |||

| Tempering Options: | Chemical Strengthened | |||

| Coating Options: | Anti-glare/Anti-reflective/Anti-fingerprint/Anti-scratches/ITO | |||

| Printing Options: | Silk Screen Printing/UV Printing | |||

| Package: | Safety plywood packaging | |||

| Place of Origin | Guangdong,CN | |||

| Gorilla® Glass 3 | Gorilla® Glass 5 | Gorilla® Glass Victus | Corning® Eagle XG® | |

| Softening Point | ~900°C | ~720°C | ~760°C | ~700°C |

| Annealing Point | ~628°C | ~560°C | ~580°C | ~550°C |

| Strain Point | ~574°C | ~510°C | ~530°C | ~500°C |

| Maximum Operating Temperature | Up to 130°C | Up to 150°C | Up to 160°C | Up to 100°C |

| Thermal Expansion Coefficient (20°C to 300°C) | 9.2 x 10⁻⁶ /K | 9.2 x 10⁻⁶ /K | 8.5 x 10⁻⁶ /K | 9 x 10⁻⁶ /K |

| Thermal Conductivity | 1.1 W/m·K | 1.1 W/m·K | 1.1 W/m·K | 0.9-1.0 W/m·K |

| Refractive Index | 1.52 | 1.51 | 1.52 | 1.52 |

| Light Transmittance | Up to 90% | Up to 91% | 92% | 78-82%(depends on coating) |

| UV Cut-off Wavelength | ~320 nm | ~320 nm | ~300 nm | ~310 nm |

| Solar Energy Transmittance | ~84% | ~85% | ~80% | 40-60%(depends on coating) |

| Coefficient of Thermal Stress | ~20 MPa/°C | ~20 MPa/°C | ~18 MPa/°C | ~16 MPa/°C |

| Density | 2.40 g/cm³ | 2.40 g/cm³ | 2.5 g/cm³ | 2.5 g/cm³ |

| Young's Modulus | 70 GPa | 73GPa | 72 GPa | 71 GPa |

| Hardness (Moh’s Scale) | 6-7 | 6-7 | 5-6 | 5-6 |

| Poisson's Ratio | 0.23 | 0.23 | 0.23 | 0.23 |

| Bending Strength | ~650 MPa | ~700MPa | ~600MPa | ~550MPa |

Customer Visit

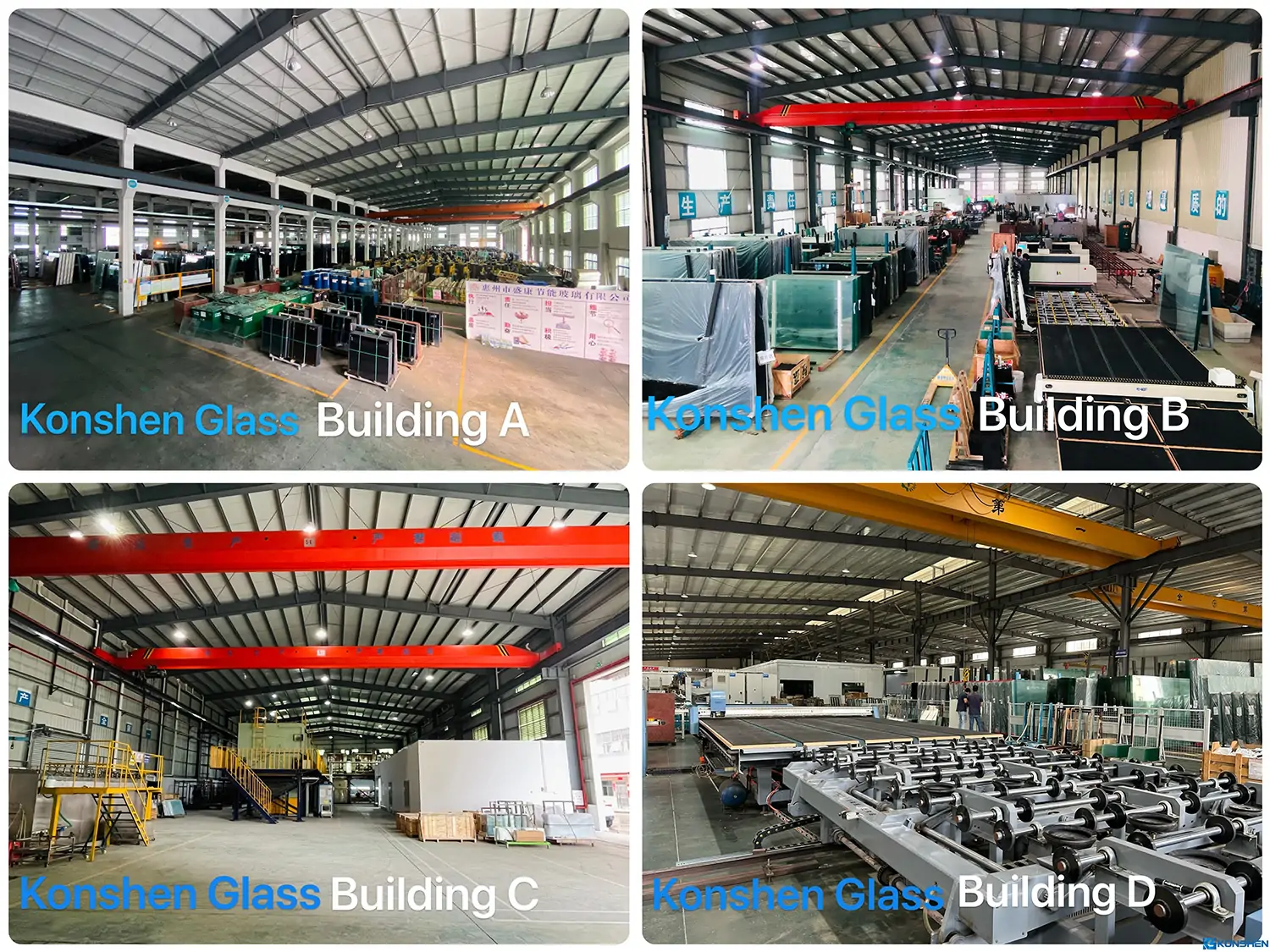

Company Profile

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us