Key Features:

Ultra-Thin & High Strength: Despite its 0.8mm ultra-thin profile, this glass delivers exceptional mechanical strength thanks to advanced chemical strengthening. It is ideal for compact devices that demand both minimal thickness and maximum durability.

Superior Optical Clarity: With a light transmittance of ≥91%, this glass guarantees high-definition visual performance, minimal distortion, and accurate color reproduction—essential for optical systems and photography lenses.

Advanced Chemical Strengthening: The chemical tempering process enhances the glass surface hardness and impact resistance, ensuring longevity and reducing the risk of cracks or breakage in demanding environments.

Precision Black Printing: Integrated black screen printing not only improves the appearance but also provides excellent masking for internal components, allowing seamless integration into modern device designs.

Enhanced Scratch and Wear Resistance: Designed for frequent handling and long-term use, the surface maintains clarity and smoothness even under abrasive conditions, making it suitable for professional applications.

Customizable for Diverse Applications: Available in different diameters, printing designs, and edge treatments (such as polished safety edges), making it adaptable for various electronic and optical devices.

Customized Option:

Available Thickness: Ranging from 0.1 mm to 15 mm, depending on the insulation requirements and specific applications.

Size & Shape: Supports special-shaped cutting to meet diverse needs. Customizes as per drawing.

Cutting Option:CNC Cutting/Water jet Cutting/Diamond Blade Cutting

Edge Options: Polished Edge/Safety Edge/Beveled Edge/Smooth Edge/2.5D Edge/Pencil Edge/Straight Edge

Tempering Options: Physical Tempered/Checmical Strengthened

Coating Options: Anti-Reflective (AR) Coating/Anti-Fingerprint (AF) Coating/Scratch-Resistant Coating/Indium Tin Oxide(ITO) Coating or Anti-Glare (AG)Coating

Printing Options: UV Printing/Silk screen printing/Laser engraving printing

Adhesive Options: AB Tape/ Double-side Tape/3M Adhesive

Materials: High-Aliminum Glass

Shape: Round

Thickness: 0.8mmT

Edge Work: Safety edge by CNC machine

Tempered Method: Chemical Strengthened

Printing Method: Silk screen printing #RAL9004 BK

Light Transmittance: 92.5%

Density: 2.5 g/cm³

Hardness: at least 6H

Strengthness: IK07

Operating Temperature Range: Suitable for -30°C to 250°C.

Thickness Tolerances:± 0.1mm

Dimensional Tolerances:±0.5mm for large size; ±0.1mm for small size

Weather Resistance: Strong resistance to high temperatures and humidity, reducing aging effects

UV Resistance: High UV-blocking capability

Impact Resistance: 2-5 times stronger than standard glass. Specific impact resistance can vary based on thickness and treatment.

Photography and Camera Lenses: Perfect for high-end cameras, professional lenses, and optical filters, offering maximum clarity and protection without compromising image quality.

Advanced Electronic Devices: Commonly used as a cover glass for sensors, control panels, and display modules in smart home devices, industrial equipment, and portable electronics.

Optical Instruments and Laboratory Equipment: Designed for instruments requiring high transparency and precision, such as microscopes, spectrometers, and imaging systems.

Smart Wearable Technology: Ideal for smartwatches and compact electronic gadgets, providing both stylish design and robust protection in everyday use.

Professional Imaging and Detection Devices: Excellent choice for high-accuracy detection systems, imaging sensors, and specialized industrial cameras, where performance and durability are critical.

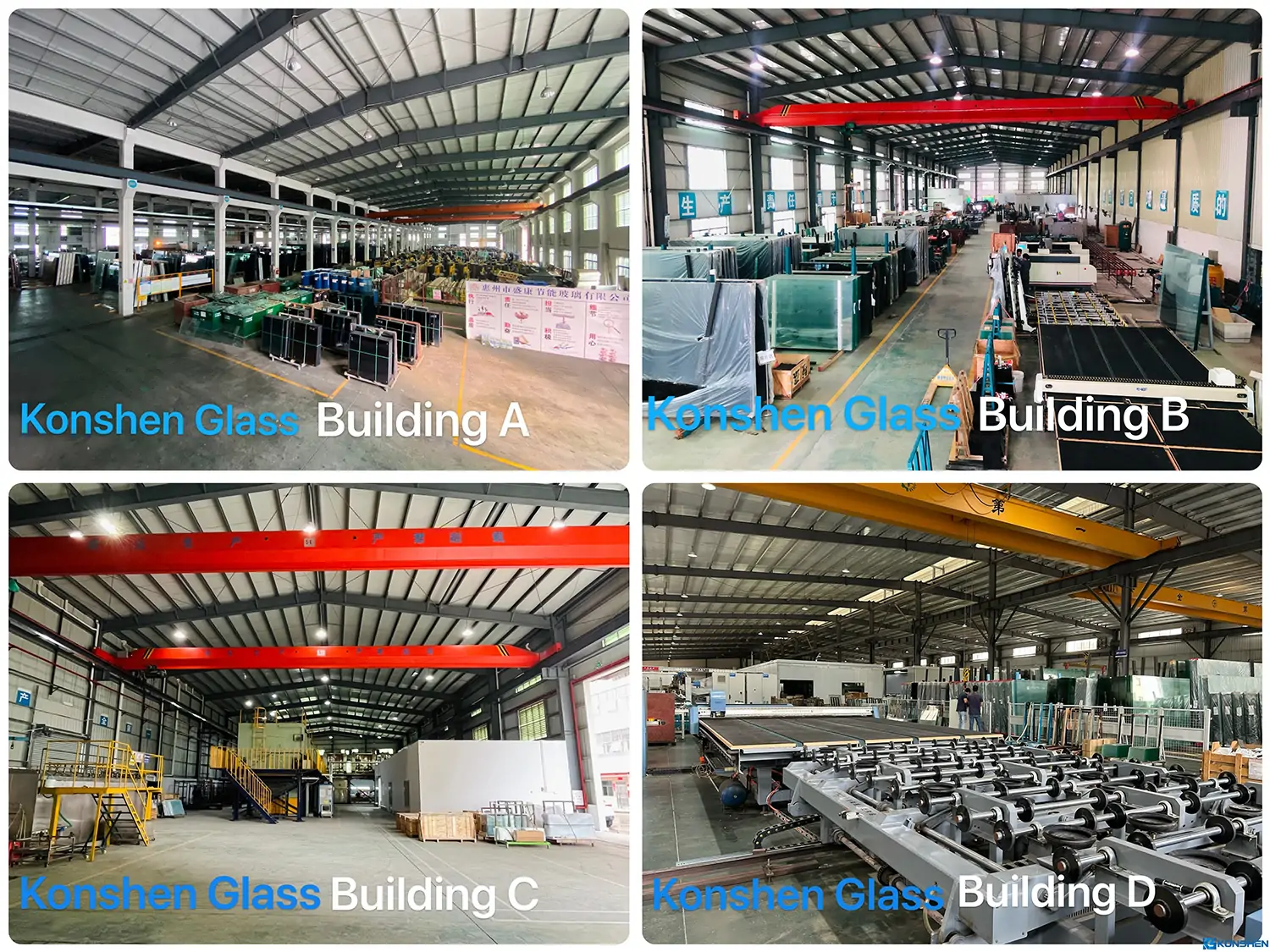

Customer Visit

Company Profile

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us