| Composition: | SiO₂ (Silicon Dioxide): ~70-75% |

| MgO (Magnesia): ~0-2% | |

| Fe₂O₃(Iron Oxide ): <0.01% | |

| CaO (Lime):10-13% | |

| Na₂O (Sodium Oxide/Soda) : ~12-15% | |

| Al₂O₃ (Aluminum Oxide): ~1-2% | |

| Thermal Properties | Softening Point: 720°C-750°C (1328°F to 1382°F) |

| Annealing Point: 550°C-600°C(1022°F to 1112°F) | |

| Strain Point: 500°C-520°C(932°F to 968°F) | |

| Maximum Operating Temperature: 400°C-450°C(752°F to 842°F) | |

| Thermal Expansion Coefficient (20°C to 300°C): 9.0 × 10⁻⁶/°C | |

| Thermal Conductivity:0.93 W.m/m2°C | |

| Coefficient of Thermal Stress:0.62 mPa/°C | |

| Optical Properties | Refractive Index: 1.50-1.52 |

| Light Transmittance: >91% | |

| UV Cut-off Wavelength: ~350 nm | |

| Solar Energy Transmittance:Up to 90% for solar panel appliction | |

| Mechanical Properties | Density: 2.5 g/cm³ |

| Young's Modulus: 70-75 GPa | |

| Hardness (Moh’s Scale):5 to 6 | |

| Tempered Strength:Up to IK07 or higher, depending on thickness and coatings. | |

| Poisson's Ratio: 0.20-0.25 | |

| Bending Strength: 80-120 MPa |

Customer Visit

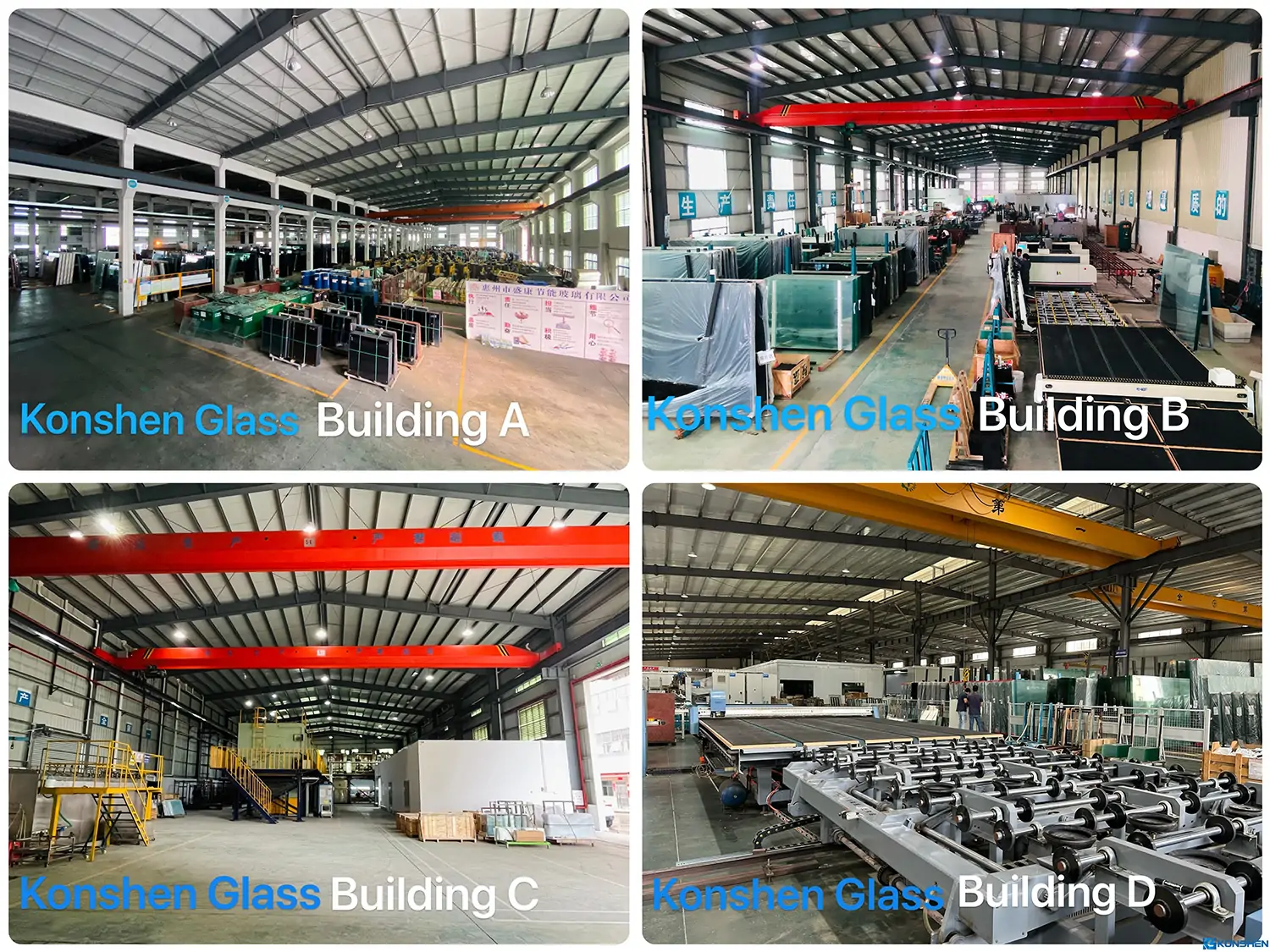

Company Profile

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us